GE Profile UPVH890 Operating instructions

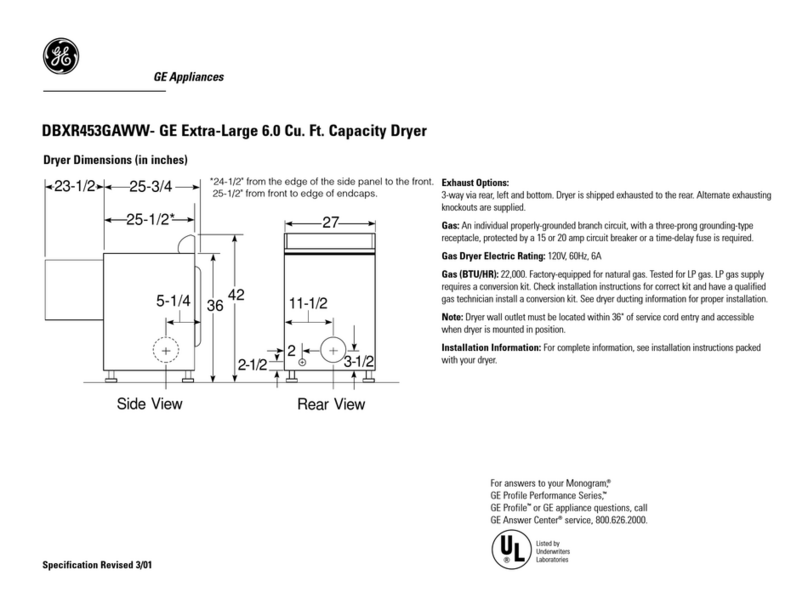

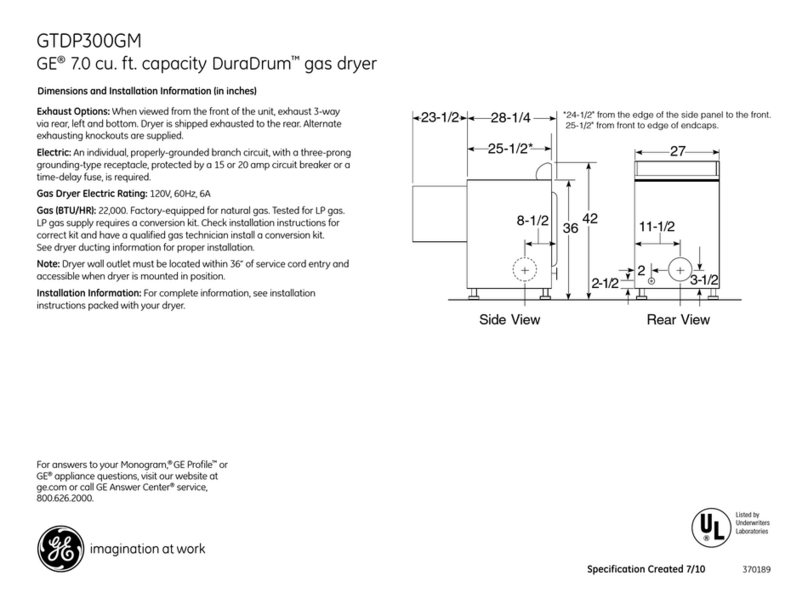

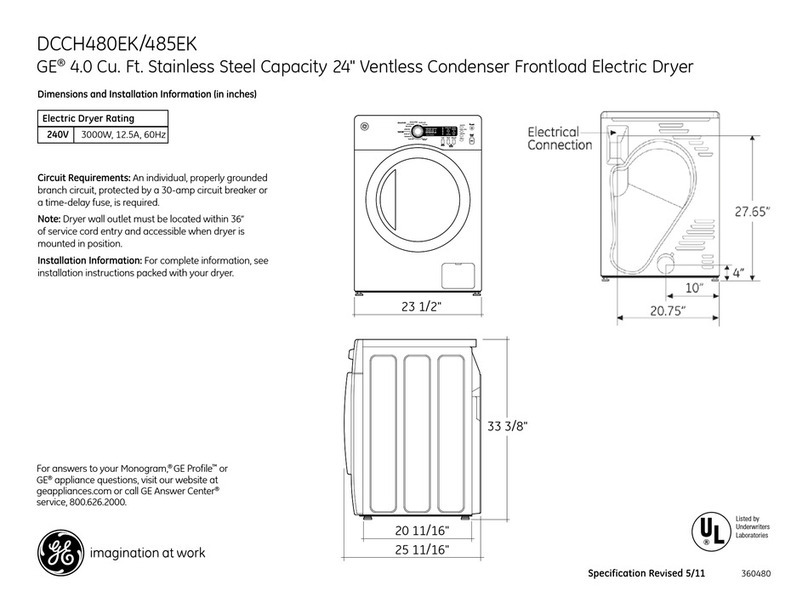

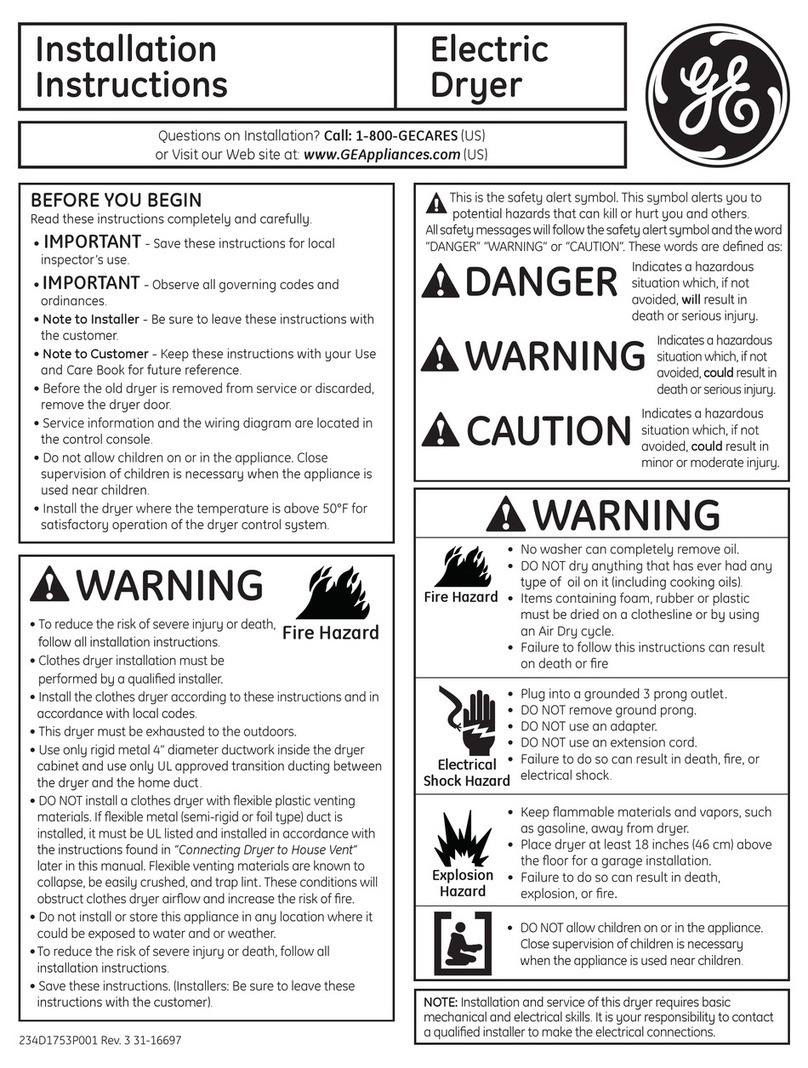

Other GE Dryer manuals

Popular Dryer manuals by other brands

Alliance Laundry Systems

Alliance Laundry Systems TMB795C Installation

Asko

Asko T793C operating instructions

Kenmore

Kenmore 8041 - 5.8 cu. Ft. Capacity Electric Dryer installation instructions

Frigidaire

Frigidaire CAQE7077KW0 use & care

Bosch

Bosch WTX8HKM9SN User manual and installation instructions

Sharp

Sharp KD-NHH9S7GW2-PL user manual