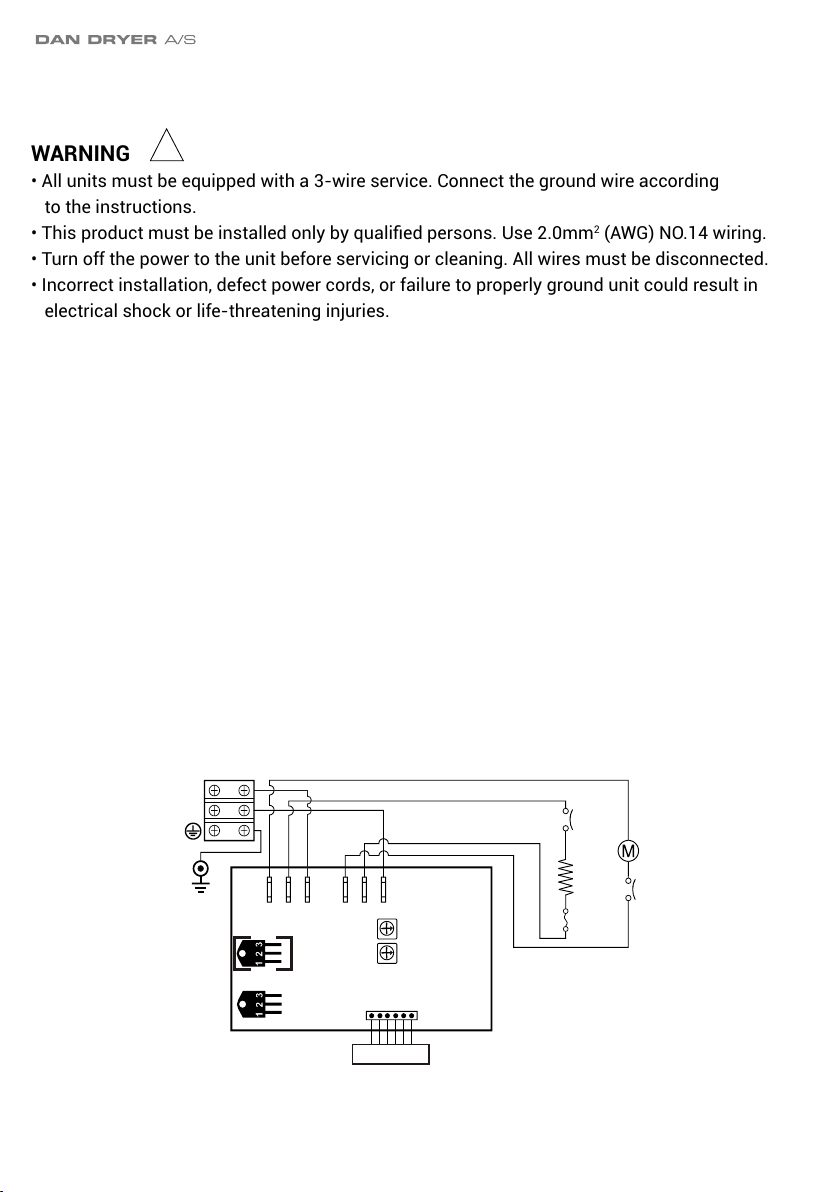

SYMPTOM CORRECTIVE ACTION: FIRST-TIME INSTALLED HAND

DRYERS

The dryer does not run First ensure that the breaker supplying the dryer is opera-

tional. If it is, disconnect the power and remove the cover.

Taking suitable precaution to avoid shock hazard, recon-

nect the power and check for voltage on the terminal block.

Verify that connections are made correctly.

The dryer cycles by itself and

runs constantly Ensure that there is no obstruction on or in front of the IR

sensor. Clean any dirt off the sensor lens. If problem per-

sists, replace the sensor.

The dryer is very loud and

does not run for a complete

cycle

Ensure that the supply voltage is correct. The dryer will

make a loud humming noise if the input voltage is too high.

Verify voltage requirement on the unit rating label and

correct accordingly. If PCB is damaged, replace unit as well

as IR sensor.

The dryer runs, but the

airspeed is low Ensure that the supply voltage is correct. The dryer will run

slowly if the input voltage is too low.

SYMPTOM CORRECTIVE ACTION: USED HAND DRYERS

The dryer does not run First ensure that the breaker supplying the dryer is opera-

tional. If it is, disconnect the power and remove the cover.

Replace PCB and IR sensor. Taking suitable precaution to

avoid shock hazard, reconnect the power and check for vol-

tage on the terminal block.

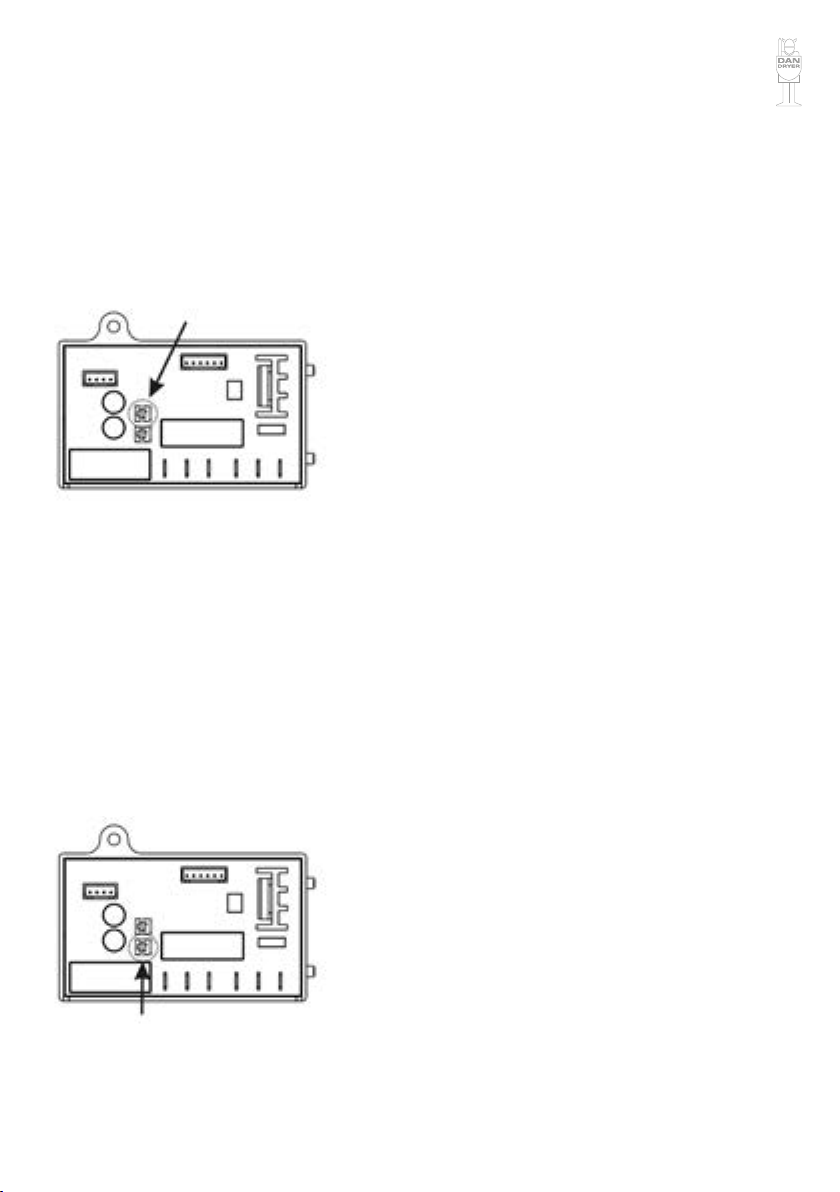

The IR-sensor detects only

close range objects Ensure that there is no obstruction on or in front of the IR

sensor. Clean any dirt off the sensor lens. If problem per-

sists, disconnect the power and remove the cover. Taking

suitable precaution to avoid shock hazard, reconnect the

power and try carefully adjusting the sensitivity range (yel-

low slot in blue component on PCB). If problem persists,

replace IR sensor.

The dryer gets hot, but there is

no air stream Disconnect the power. Remove the cover and disassemble

the blower/fan unit. Replace motor.

The dryer blows only cold air

during a full cycle Disconnect the power. Remove the cover and disassemble

the blower/fan unit. Test the thermostate for open circuit.

Check the heating element for defects. Replace defect

heating element.

The air pressure is low Check the output nozzle for obstructions. If none, discon-

nect the power and remove the cover. Remove any dirt from

the inlet. Disassemble the blower/fan unit, check if motor

brushes are worn (≤ 10 mm graphite remains) and replace

them, if necessary.