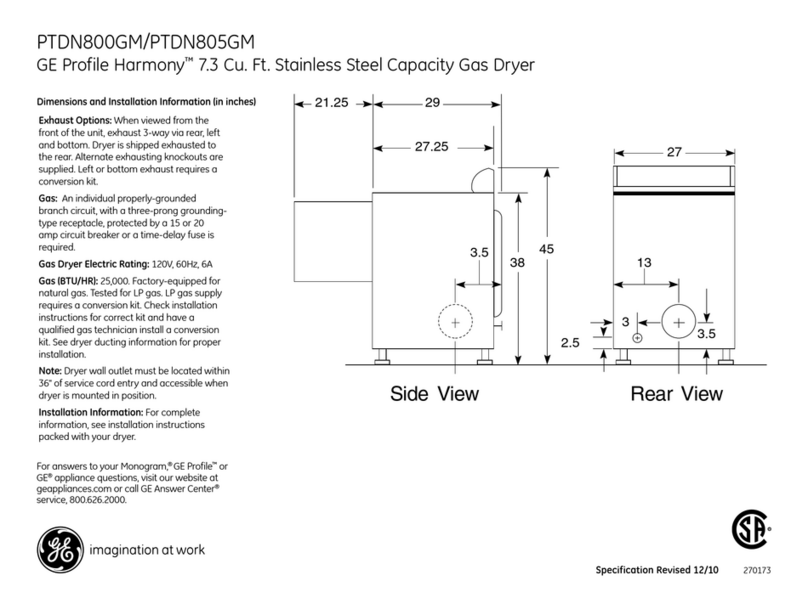

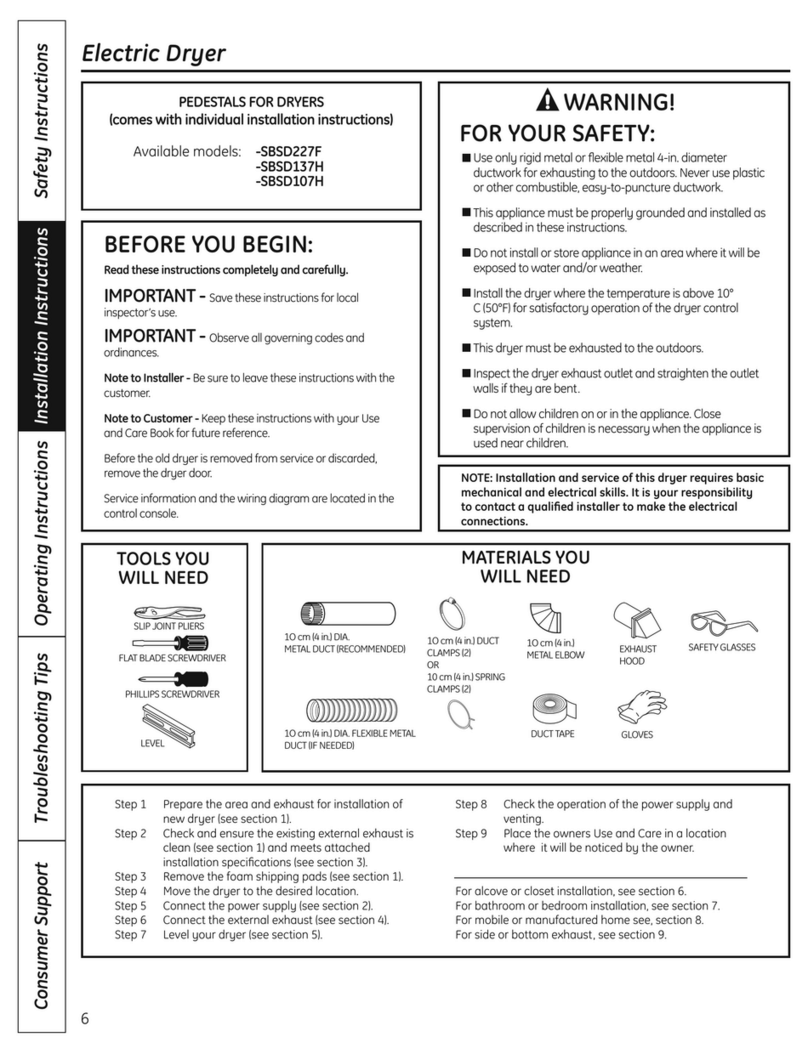

Installation

Instructions Electric

Dryer

or Visit our Web site at: www.GEApplionces.com (US) J

BEFORE YOU BEGIN

Readthese instructions completely and carefully.

, IMPORTANT - save these instructions for local

inspector's use.

, IMPORTANT - Observe all governing codes and

ordinances.

, Note to Installer - Be sure to leave these instructions with

the customer.

, Note to Customer - Keep these instructions with your Use

and Care Bookfor future reference.

, Before the old dryer is removed from service or discarded,

remove the dryer door.

, Service information and the wiring diagram are located in

the control console.

, Do not allow children on or in the appliance. Close

supervision of children is necessary when the appliance is

used near children.

, Install the dryer where the temperature isabove 50°Ffor

satisfactory operation of the dryer control system.

AWAR IG

, Toreduce the riskof severe injury or death, Fire Hazard

follow all installation instructions.

, Clothesdryer installation must be

performed by a qualified installer.

, Install the clothes dryer according to these instructions and in

accordance with local codes.

, Thisdryer must be exhausted to the outdoors.

, Use only rigid metal 4" diameter ductwork insidethe dryer

cabinet and use only ULapproved transition ducting between

the dryer and the home duct.

, DONOTinstall a clothes dryer with flexible plastic venting

materials. If flexible metal (semi-rigid or foil type)duct is

installed, it must be ULlisted and installed in accordance with

the instructions found in "ConnectingDryer to House Vent"

later in this manual. Flexibleventing materials are known to

collapse,be easily crushed, and trap lint. These conditions will

obstruct clothes dryer airflow and increase the risk of fire.

, Do not install or store this appliance in any location where it

could be exposed to water and or weather.

,To reduce the risk of severe injury or death, follow all

installation instructions.

, Savethese instructions. (Installers: Besure to leave these

instructions with the customer).

234DI753P001Rev. 5 31-16697

_lk This isthe safety alert symbol. This symbol alerts you to

potential hazards that can kill or hurt you and others.

Allsafety messageswillfollowthe safety alertsymbol and the word

"DANGER""WARNING"or "CAUTION".Thesewords are defined as:

DANGER Indicates a hazardous

situation which, if not

avoided, will result in

death or serious injury.

A WAR I G Indicatesa hazardous

situationwhich,if not

avoided,could resultin

death or seriousinjury.

CAUTIO Indicates a hazardous

situation which, if not

avoided, could result in

minor or moderate injury.

AWA I G

Fire Hazard

, Nowasher can completely remove oil.

, DONOTdry anything that has ever had any

type of oil on it (including cooking oils).

, Items containing foam, rubber or plastic

must be dried on a clothesline or by using

an Air Dry cycle.

, Failure to follow this instructions can result

on death or fire

o

o

Q

o

Electrical "

Shock Hazard

Plug into a grounded 3 prong outlet.

DONOTremove ground prong.

DONOTuse an adapter.

DONOTuse an extension cord.

Failure to do so can result in death, fire, or

electrical shock.

Explosion

Hazard

, Keep flammable materials and vapors, such

as gasoline, away from dryer.

, Placedryer at least 18 inches (46 cm) above

the floor for a garage installation.

, Failure to do so can result in death,

explosion, or fire.

, DONOTallow children on or inthe appliance.

Closesupervisionof children isnecessary

when the appliance isusednear children.

NOTE:Installation and serviceof this dryer requires basic

mechanical and electrical skills.It is your responsibility to contact

a qualified installerto make the electrical connections.