FP1500 Installation, Configuration and Commissioning Manual 1

CONTENTS

1Introduction............................................................................................................................................ 3

1.1 Contents of the package ............................................................................................................... 3

1.2 Glossary of symbols...................................................................................................................... 4

1.3 The FP1500 analogue system ......................................................................................................4

1.4 Safety precautions and warnings.................................................................................................. 5

2The FP1500 analogue fire panel........................................................................................................... 7

2.1 Description of the control panel .................................................................................................... 7

2.2 Access levels and authorization codes ......................................................................................... 8

2.3 Features and functions.................................................................................................................. 9

3Installation of the system ................................................................................................................... 10

3.1 Installation tools .......................................................................................................................... 10

3.2 Panel positioning......................................................................................................................... 11

3.3 Fixing the fire panel to the wall ................................................................................................... 11

3.4 Selecting a language................................................................................................................... 11

3.5 Electrical connections and cables ...............................................................................................12

3.5.1 Connecting power........................................................................................................ 12

3.5.2 Connections on the main electronic board .................................................................. 14

3.5.3 Connecting a loop........................................................................................................ 14

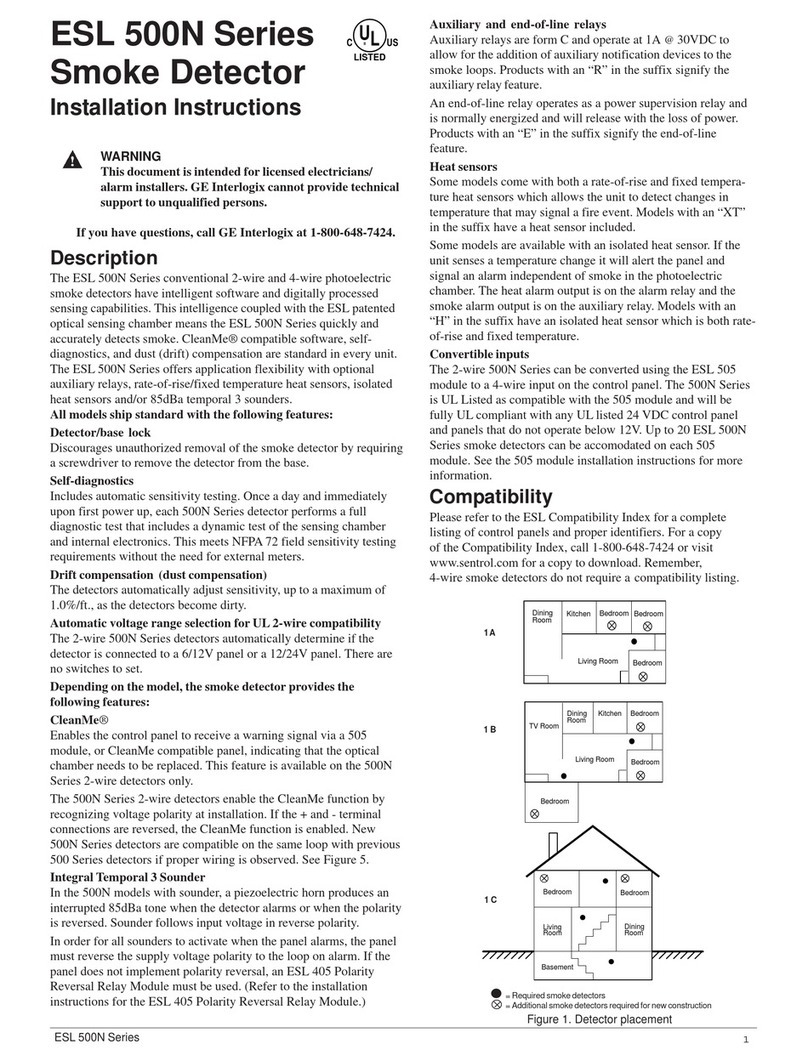

3.5.4 Connecting sensors ..................................................................................................... 16

3.5.5 Connecting modules .................................................................................................... 17

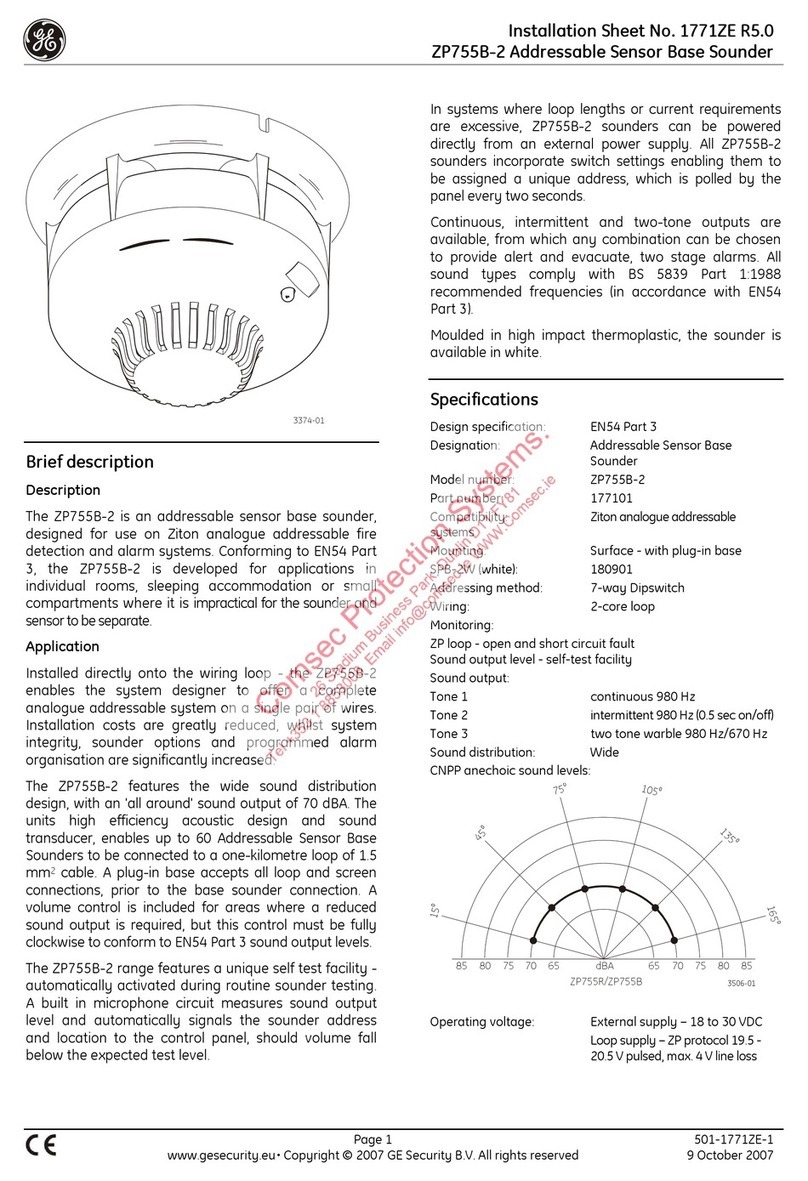

3.5.6 Connecting sounders................................................................................................... 18

3.5.7 Connecting relays ........................................................................................................ 19

3.6 Mounting optional elements ........................................................................................................ 19

4System configuration.......................................................................................................................... 21

4.1 Basic configuration...................................................................................................................... 21

4.1.1 General parameters..................................................................................................... 22

4.1.2 Setting the Time and Date ........................................................................................... 23

4.1.3 Configuring a loop........................................................................................................ 24

4.1.4 Configuring a zone....................................................................................................... 25

4.1.5 Configuring elements................................................................................................... 26

4.1.6 Configuring sounder outputs ....................................................................................... 28

4.1.7 Configuring relay outputs............................................................................................. 30

4.2 Configuration with advanced options .......................................................................................... 31

4.2.1 Day mode setting......................................................................................................... 31

4.2.2 Sensitivity setting ......................................................................................................... 32

4.2.3 Configuration of the network........................................................................................ 33

4.2.4 Configuration of a repeater .......................................................................................... 34

4.2.5 Connection of a modem............................................................................................... 35

4.2.6 Connection to ethernet ................................................................................................ 39

4.2.7 Changing the firmware version.................................................................................... 40

4.2.8 Connection of a computer............................................................................................ 40

4.2.9 Connection to a printer ................................................................................................ 40

4.2.10 Changing the access level codes ................................................................................ 41

4.3 Graphics software ....................................................................................................................... 42

5Commissioning of the system ........................................................................................................... 43

5.1 Checking the system................................................................................................................... 43

5.2 System power up ........................................................................................................................ 43

5.2.1 Initial system configuration .......................................................................................... 43

5.3 Operational tests ......................................................................................................................... 44

5.4 Troubleshooting guide................................................................................................................. 44

5.4.1 Earth faults................................................................................................................... 44

5.4.2 Communication errors ................................................................................................. 44

5.4.3 Double addresses........................................................................................................ 45

5.4.4 CPU failure .................................................................................................................. 45

5.4.5 Out of service............................................................................................................... 46