IV!'llW:lH OlIO[,1

Before you begin--Read these instructions completely and carefldly.

IMPORTANT: Save these instructions for local inspector's use,

IMPORTANT: OBSERVE ALL GOVERNING CODES AND ORDINANCES.

NOTE TO INSTALLER: Be sure to leave these instructions with the

Coilsuiner.

NOTE TO CONSUMER: Keep these instructions with your Use and Care

Book tor flttttI'e referet/ce.

This appliance must he properly grounded. See "Electrical Supply", page 9. ]

If you have questions concerning the installa-

tion of"this product, call the (;E Answer

Center #_Consumer Information Service at

800.626.2000, 24 hours a day, 7 days a week.

Proper installation is tile responsibility of the

installer. Product fi_ilut'e due to improper installation

is not covered under tile (;E Appliance V',_lrranty. See

tile [Tse K"Care Guide tor warranty intormation.

If you received a damaged oven, you should

conutct your dealer.

CAUTION:

• This oven should be installed by a qualified

installer or service technician.

• Never use the oven tor warming or heating a

room. Prolonged use of the oven without

adequate ventilation can be hazardous.

Check with local utilities for electrical codes which

apply in your area. Local codes vary. Installation,

electrical connections and grounding must comply

with applicable codes. In tile absence of local codes,

the oven should be installed in accordance with

National Electrical Code ANSI/NFPA 70-1990.

Contents Design Information

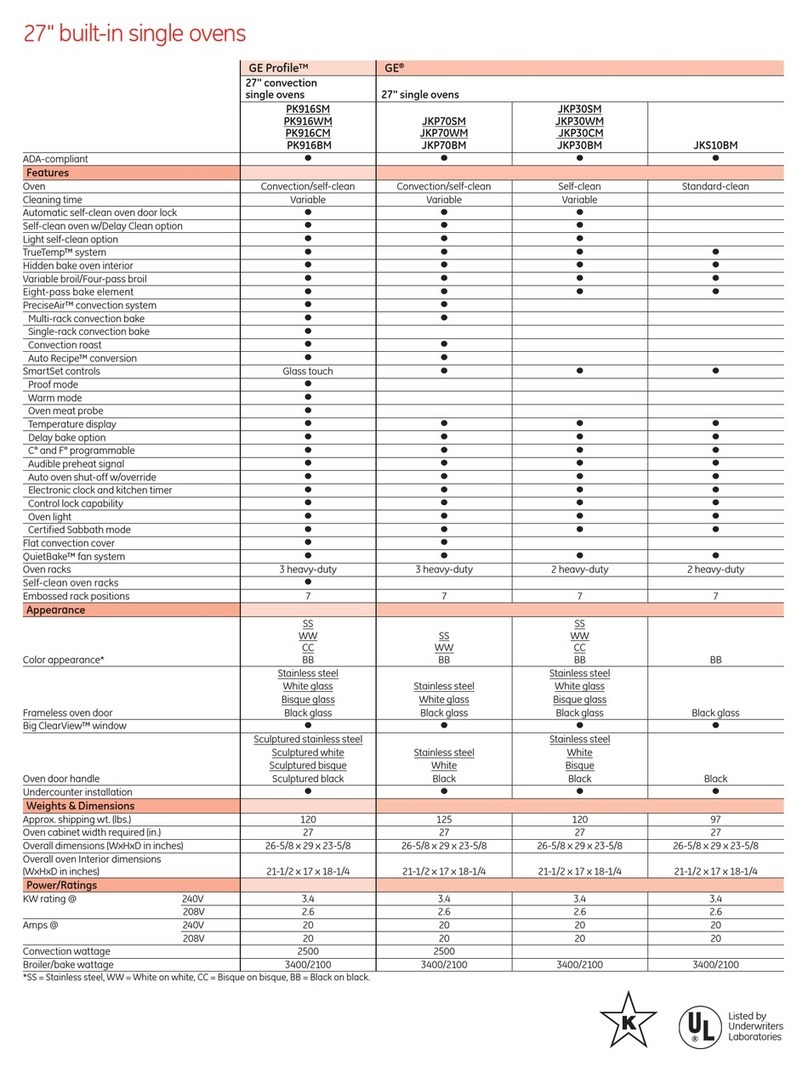

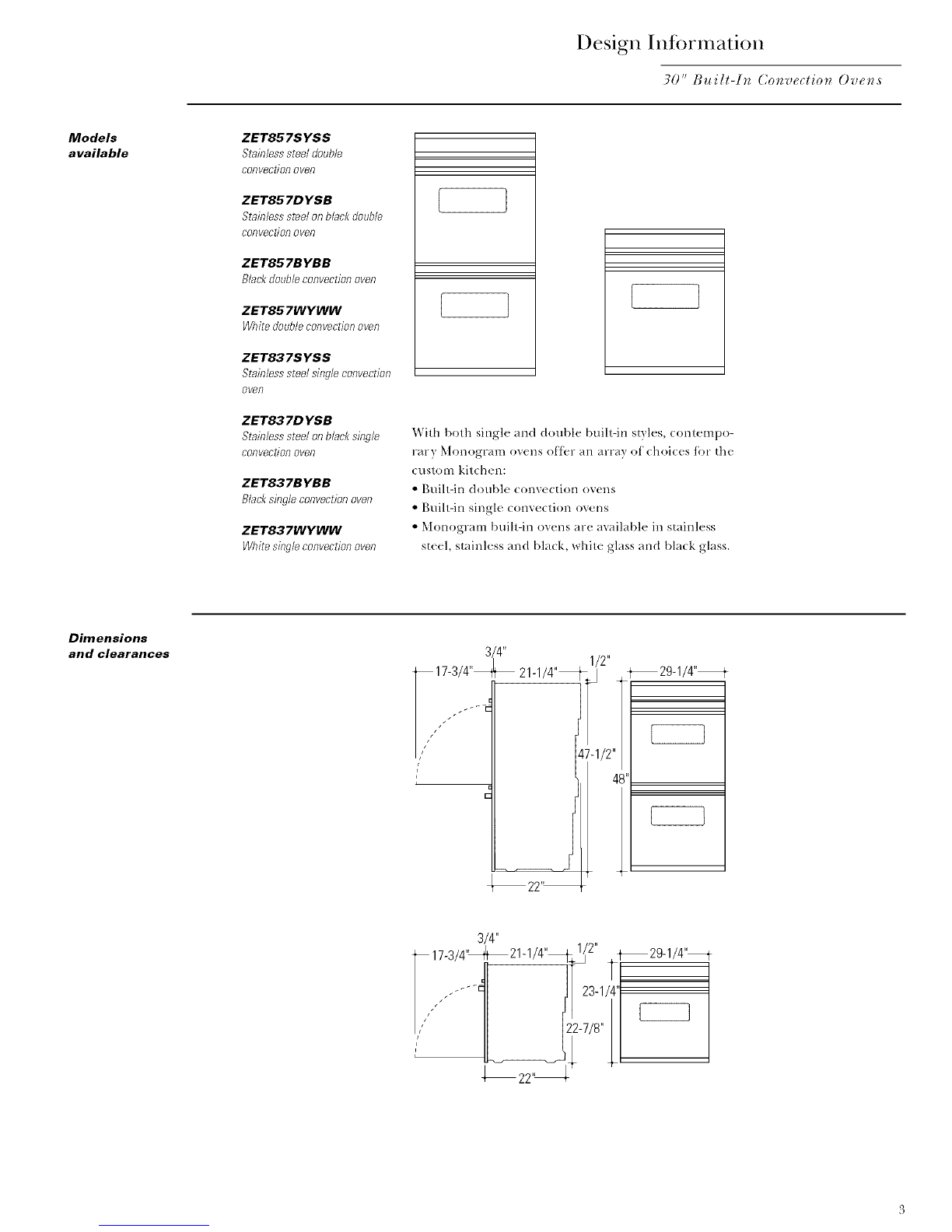

Models Available .................................................................................................................................. 3

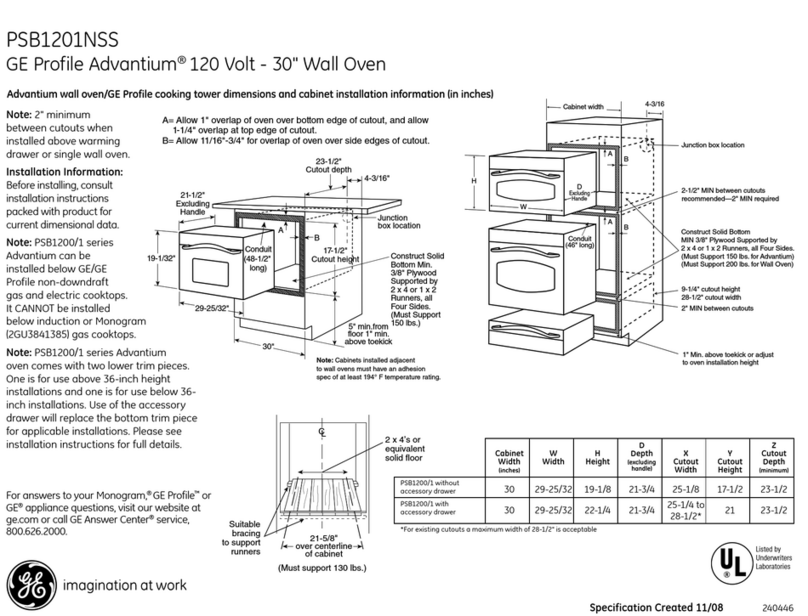

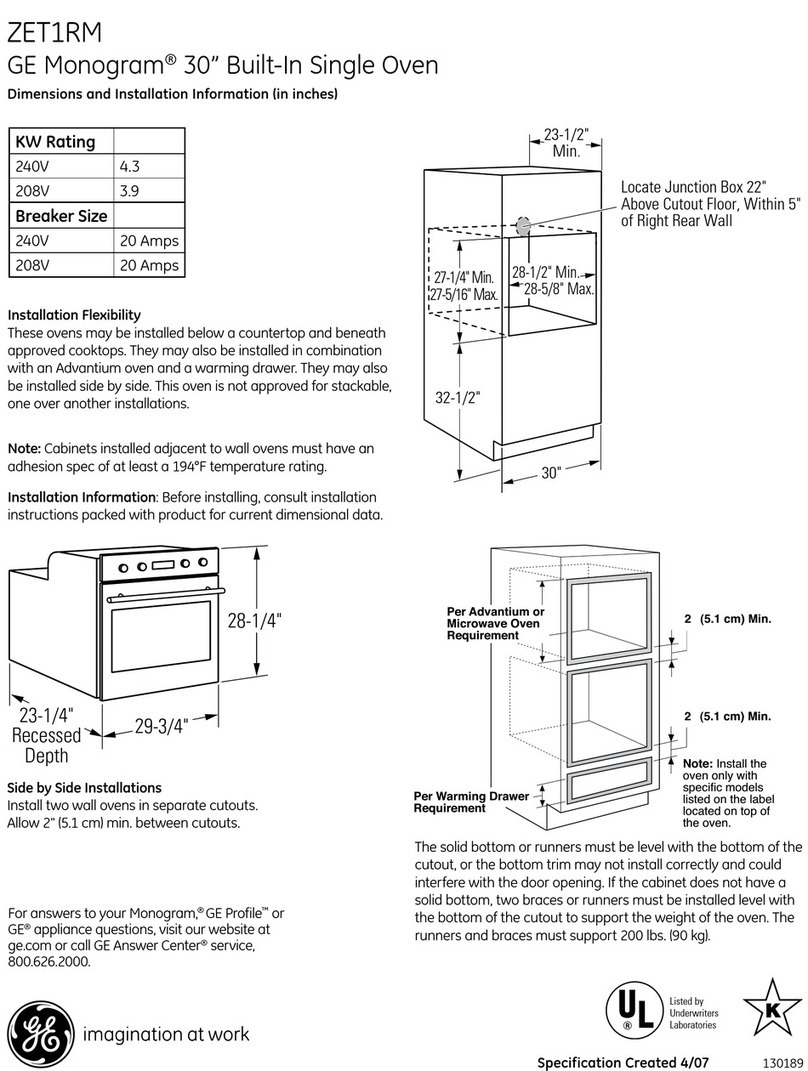

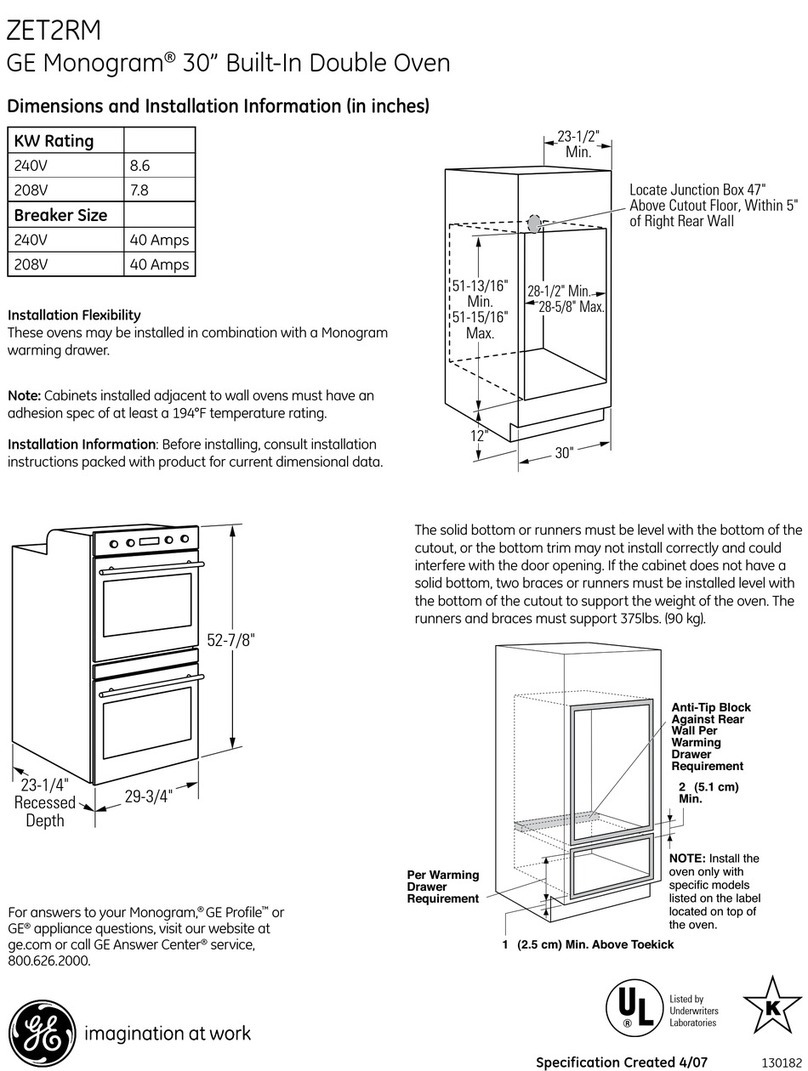

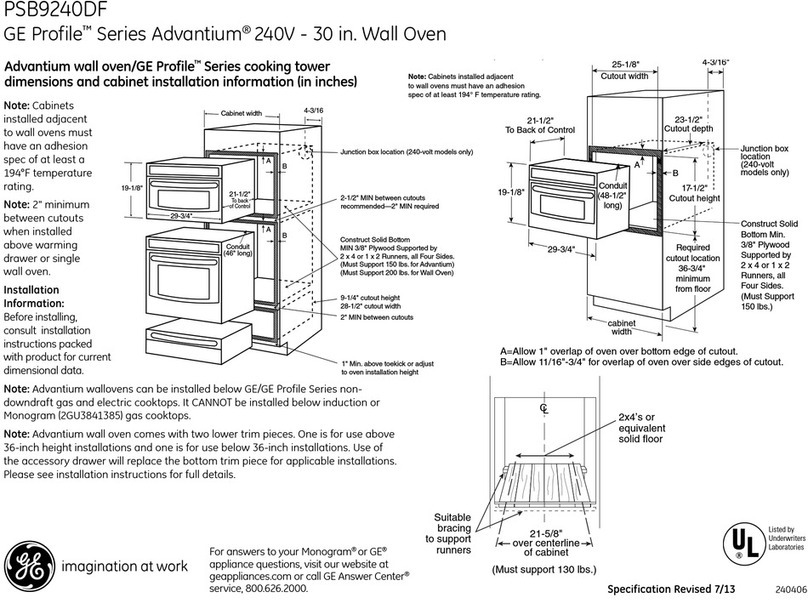

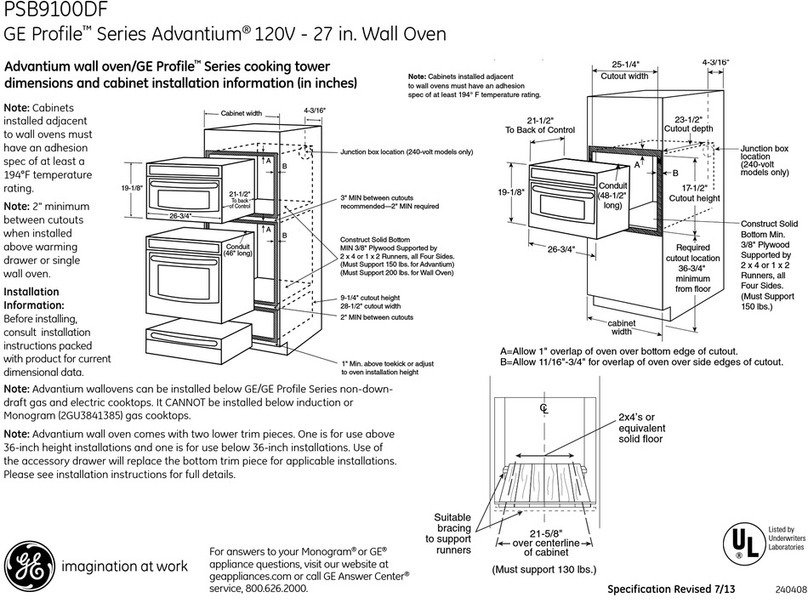

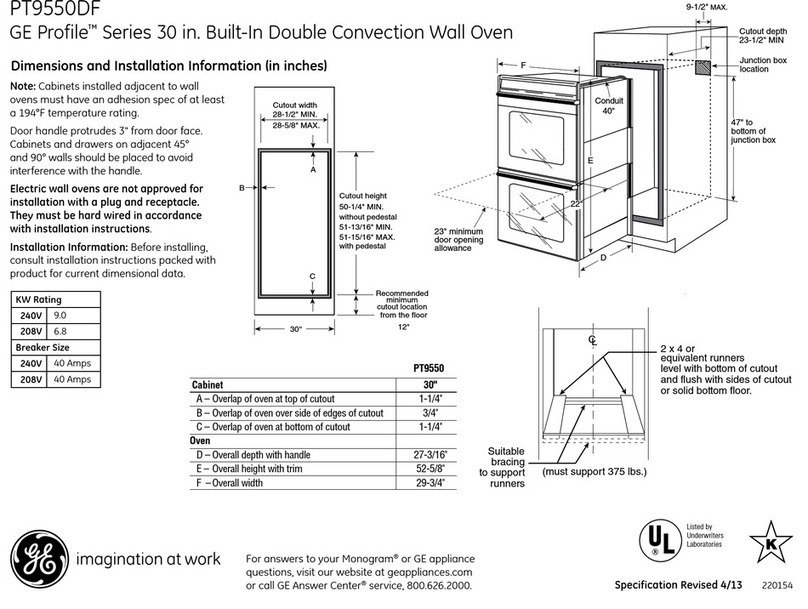

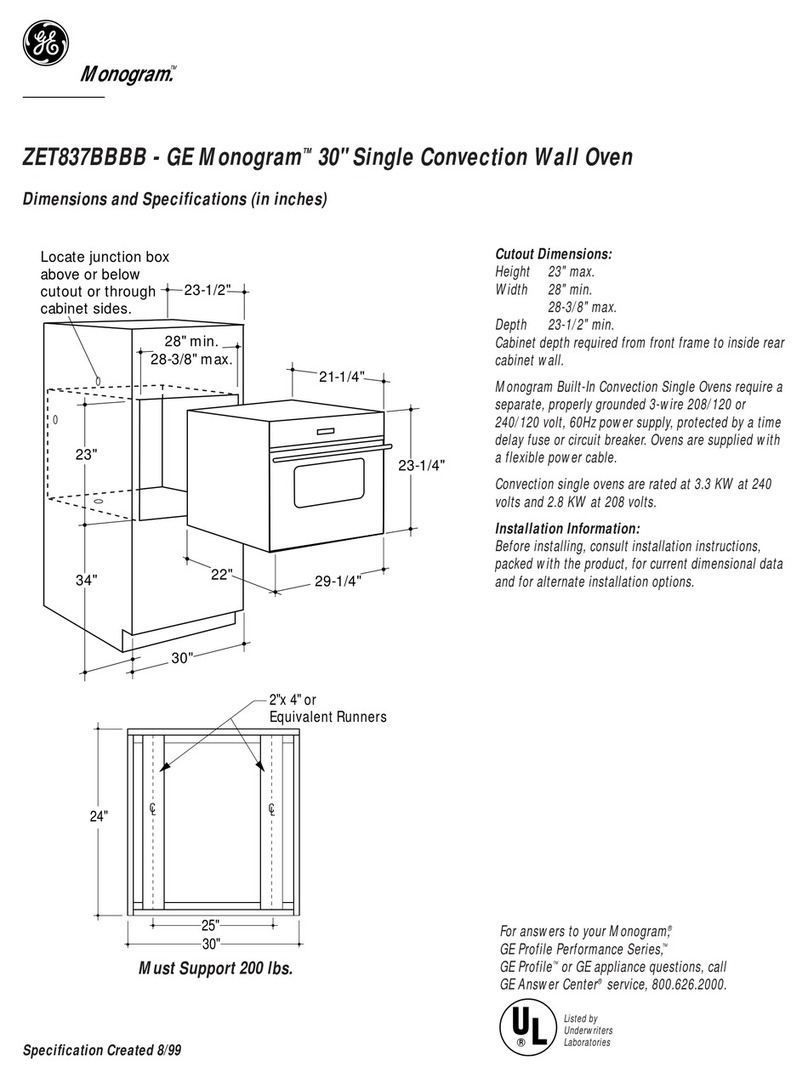

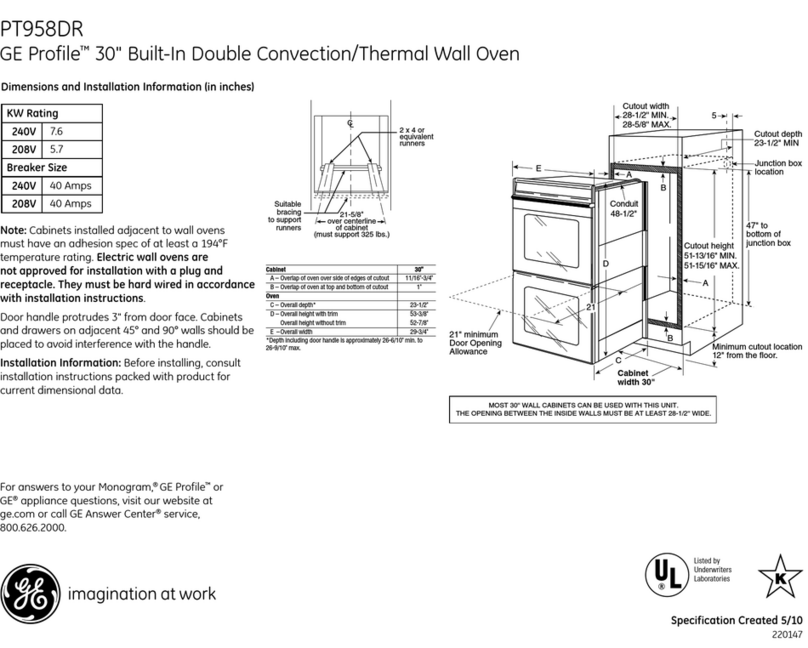

Dimensions and Clearances ............................................................................................................... 3

Cabinet Style Options ......................................................................................................................... 4

Cabinetry

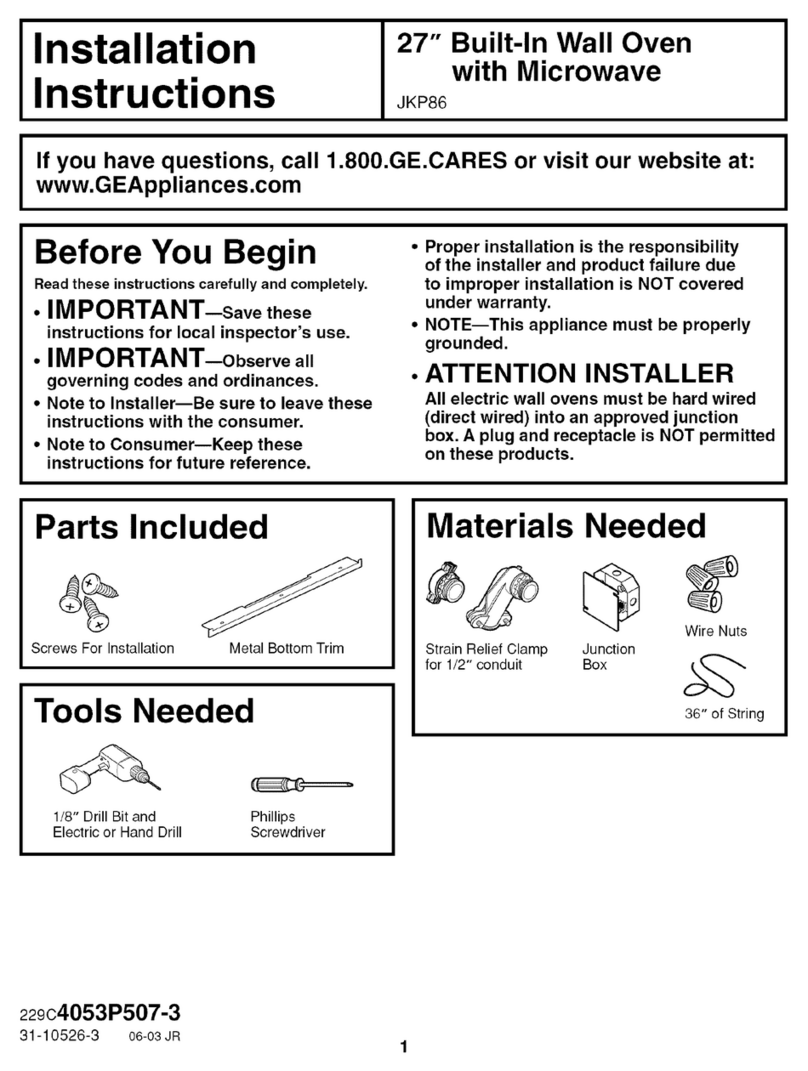

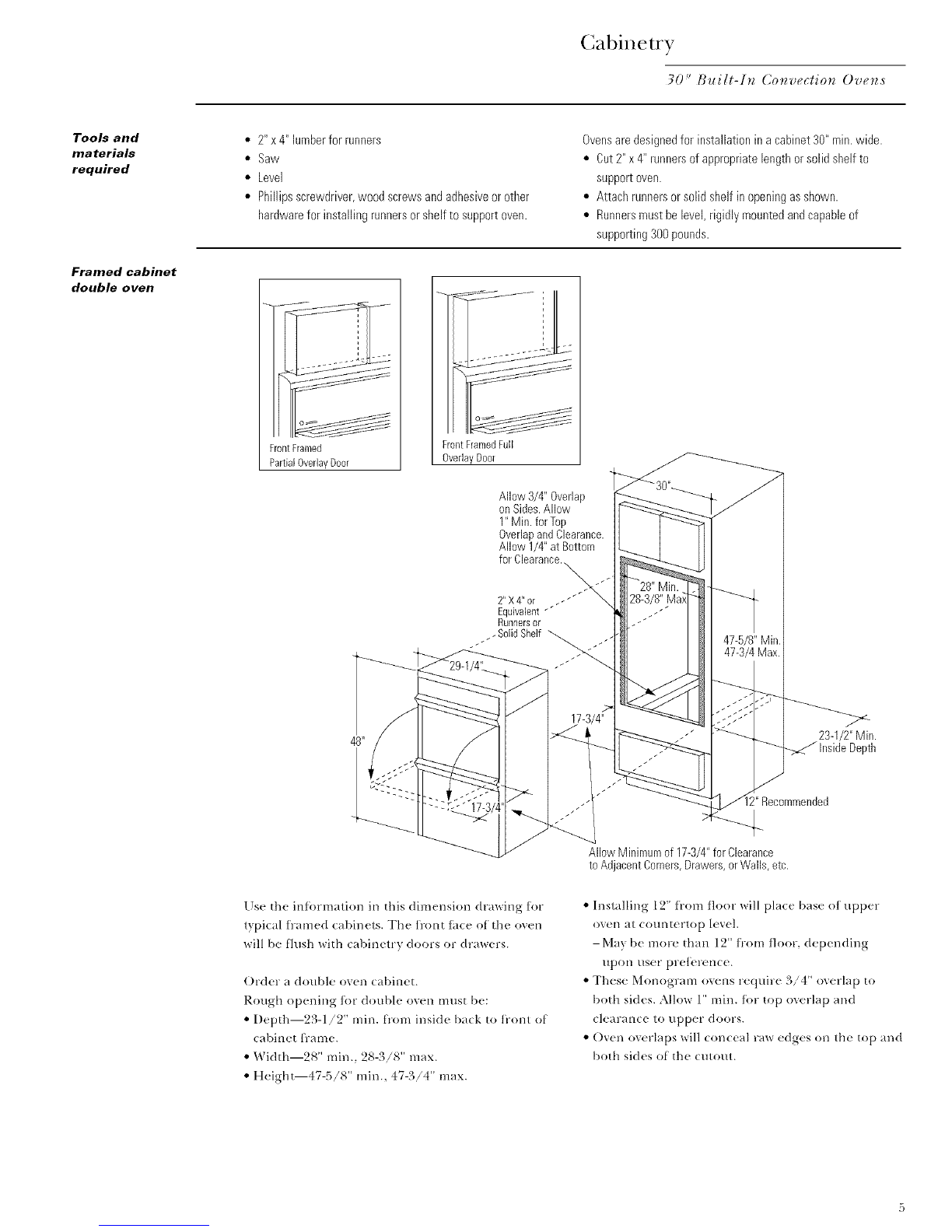

Tools and Materials req uired ............................................................................................................. 5

Framed Cabinet, Double Oven .......................................................................................................... ,_

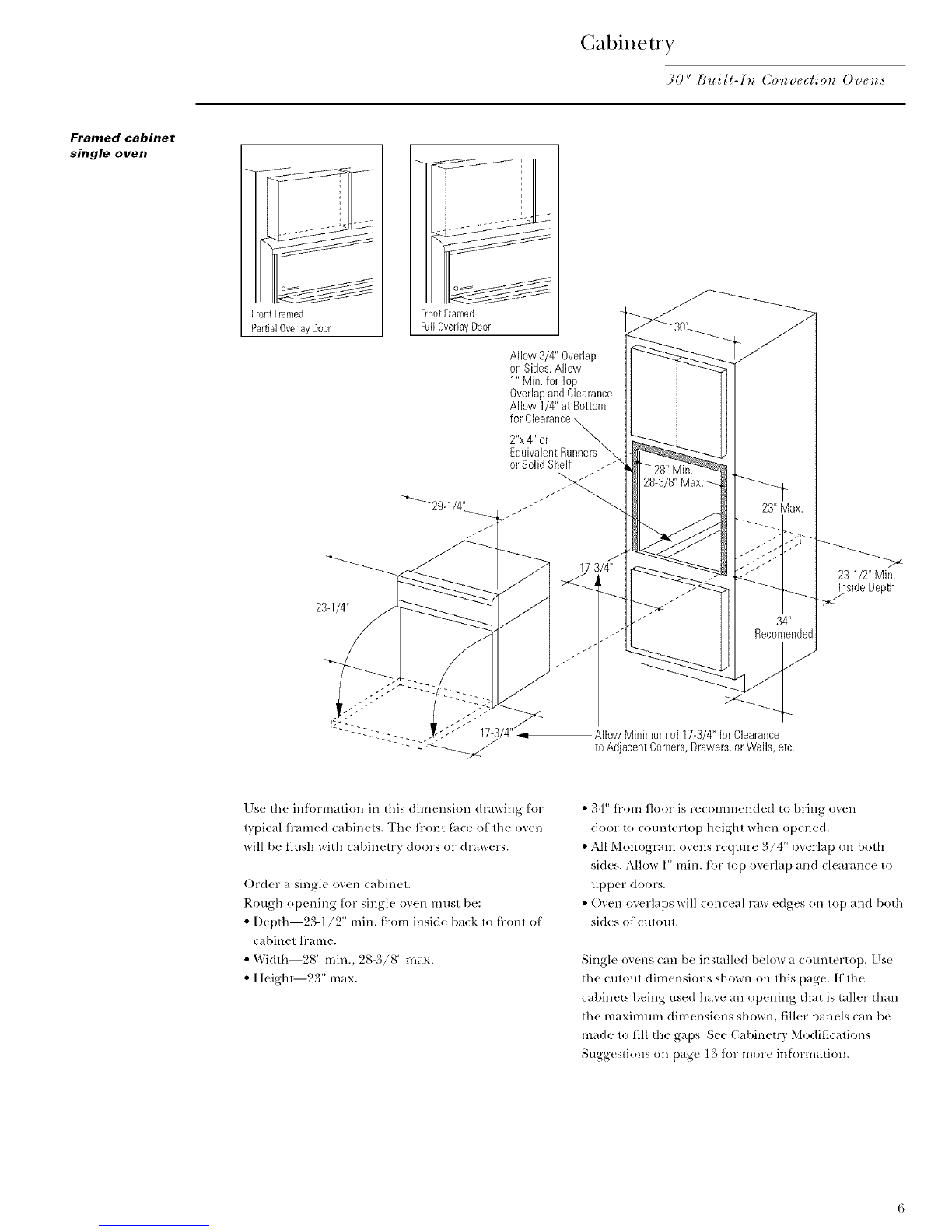

Framed Cabinet, Single Oven ............................................................................................................ 6

Fram eless Cabin ets .............................................................................................................................. 7

Installation

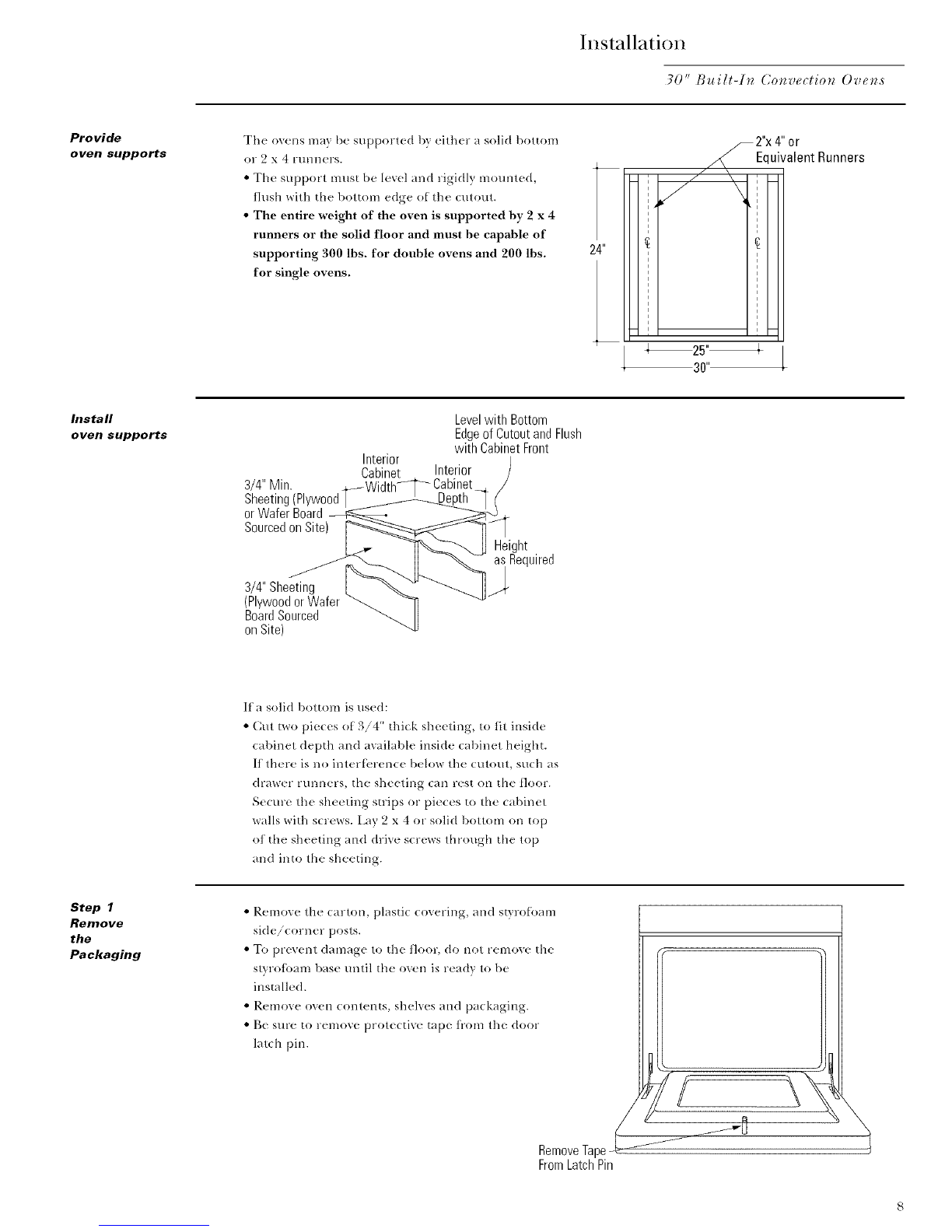

Provide Oven Supports ....................................................................................................................... 8

Install Oven Supports .......................................................................................................................... 8

Step 1: Remove the Packaging ............................................................................................................ 8

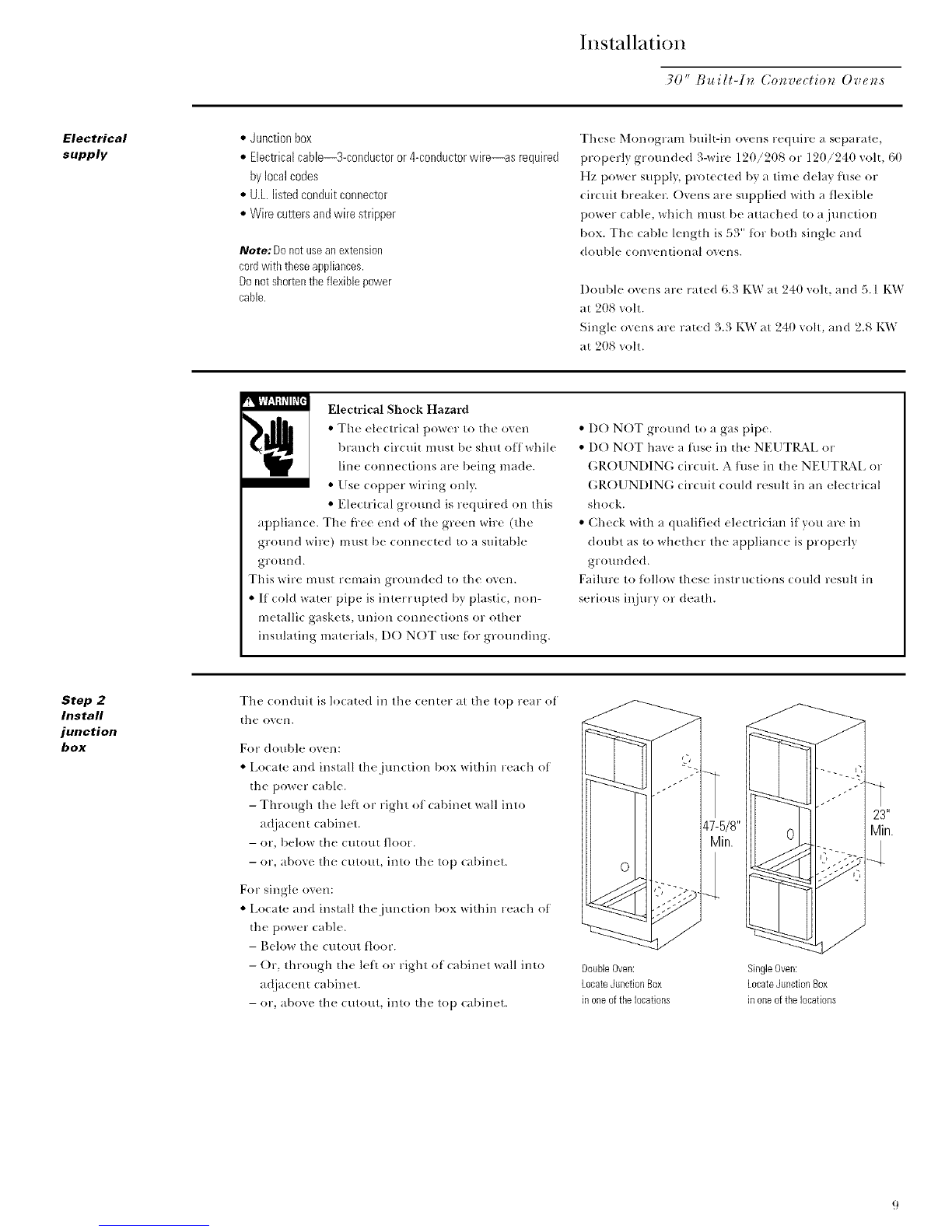

Electrical Supply .................................................................................................................................. 9

Step 2: Install.]traction Box ................................................................................................................ 9

208V Electrical Supply ....................................................................................................................... 10

Step 3: Remove Oven Doors ............................................................................................................. 11

Step 4: Rotate Cable through Ctttt)ttt ............................................................................................... l l

Step 5: Secm'e Oven to Cabinet ........................................................................................................ l 1

Step 6: Replace the Oven Door ........................................................................................................ 12

Step 7: Cmmect Electrical ................................................................................................................. 19

Cabinetry Modification Suggestions

Determine Need for Fillet" Panels ..................................................................................................... 13

Fillet" Panel Construction .................................................................................................................. 13

(',tit Rail for Fillet" Panel .................................................................................................................... 14

(:tit Appearance Panel ...................................................................................................................... 14

Determine Location of Cleats ........................................................................................................... 14

Cut and Secm'e Cleats tit Fillet" Panel ............................................................................................... 15

Secm'e Rail to Appearance Panel ..................................................................................................... 15

Secure Assembled Fillet" Panel to Cabinet ....................................................................................... 15