GE_UPS_OPM_SGS_ISG_10K_40K_0US_V070.docx

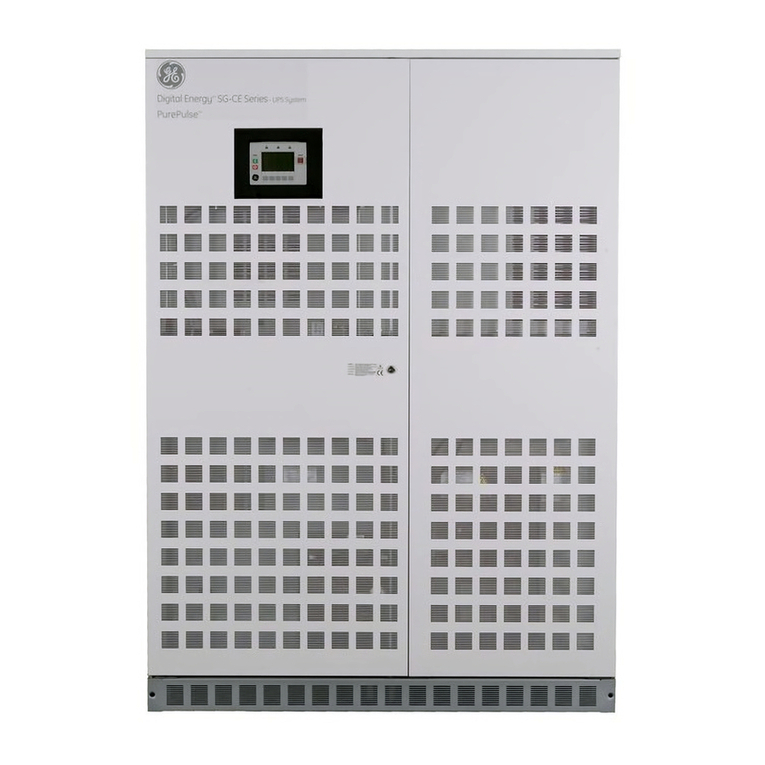

Installation Guide SG Series 10-20-30-40 UL S

Table of contents Page

1SAFETY RULES ................................................................................................................................................. 6

2LAYOUT............................................................................................................................................................. 9

2.1 LAYOUT SG SERIES 10 & 20................................................................................................................................................................... 9

2.2 LAYOUT SG SERIES 30 & 40.................................................................................................................................................................10

3INSTALLATION............................................................................................................................................... 11

3.1 TRANSPORT .................................................................................................................................................................................................11

3.1.1 Dimensions and weight ........................................................................................................................................................................ 11

3.2 DELIVERY ......................................................................................................................................................................................................12

3.3 STORAGE.......................................................................................................................................................................................................12

3.3.1 Storage of the UPS .................................................................................................................................................................................. 12

3.3.2 Storage of battery ................................................................................................................................................................................... 12

3.4 PLACE OF INSTALLATION......................................................................................................................................................................13

3.4.1 UPS location ............................................................................................................................................................................................... 13

3.4.2 Battery location ........................................................................................................................................................................................ 15

3.5 VENTILATION AND COOLING..............................................................................................................................................................16

3.6 UNPACKING.................................................................................................................................................................................................17

3.7 ELECTRICAL WIRING ...............................................................................................................................................................................19

3.7.1 Utility input connection ......................................................................................................................................................................... 19

3.7.2 Input/output over current protection and wire sizing............................................................................................................. 20

3.7.3 Battery over current protection and wire sizing........................................................................................................................ 21

3.8 WIRING CONNECTION ...........................................................................................................................................................................24

3.8.1 Power connections.................................................................................................................................................................................. 24

3.8.2 Power connection with common input utility of SG Series 10 & 20 .................................................................................. 27

3.8.3 Power connection with common input utility of SG Series 30 & 40 .................................................................................. 28

3.8.4 Power connection dual input utility of SG Series 10 & 20 ...................................................................................................... 29

3.8.5 Power connection dual input utility of SG Series 30 & 40 ...................................................................................................... 31

3.8.6 Battery connection of SG Series 10 & 20....................................................................................................................................... 33

3.8.7 Battery connection of SG Series 30 & 40....................................................................................................................................... 34

3.8.8 Set-up for SG Series 10-20-30-40 when functioning as frequency converter ............................................................. 35

3.9 RPA PARALLEL SYSTEM CONNECTION...........................................................................................................................................36

3.9.1 Power wiring of parallel units............................................................................................................................................................. 36

3.9.2 Parallel control bus connection......................................................................................................................................................... 37

3.9.3 Control bus cable location................................................................................................................................................................... 39

4CUSTOMER INTERFACE................................................................................................................................ 41

4.1 CUSTOMER INTERFACE..........................................................................................................................................................................41

4.1.1 Serial Port J3 .............................................................................................................................................................................................. 42

4.1.2 Output free potential contacts .......................................................................................................................................................... 42

4.1.3 Programmable input free contacts ................................................................................................................................................. 43

4.1.4 Gen Set Signaling (GEN ON)................................................................................................................................................................. 43

4.1.5 AUX external Maintenance Bypass.................................................................................................................................................. 43

4.1.6 Auxiliary Power Supply (APS) 24 Vdc ............................................................................................................................................... 43

4.1.7 “EPO - Emergency Power Off” command connection............................................................................................................. 44

5NOTES............................................................................................................................................................. 46

5.1 NOTES FORM ..............................................................................................................................................................................................46