Installation Instructions

ADVANCE PLANNING

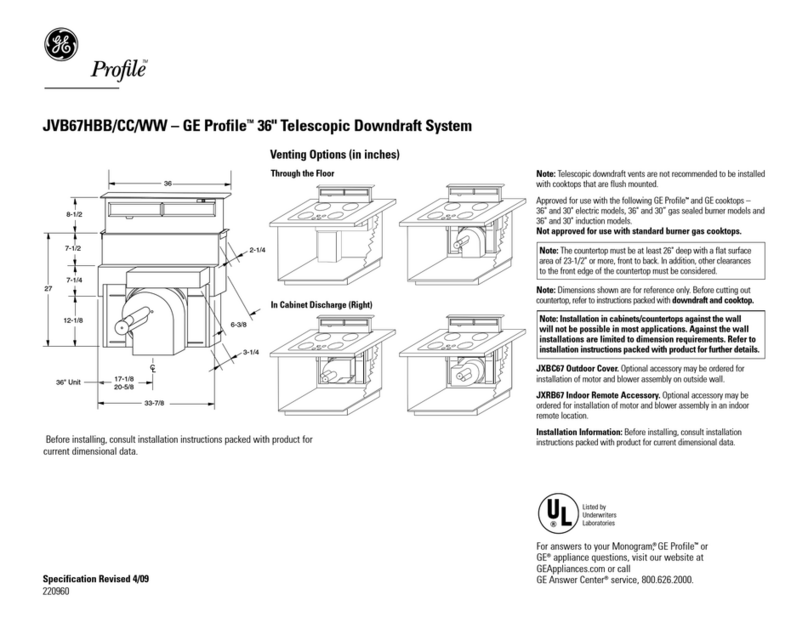

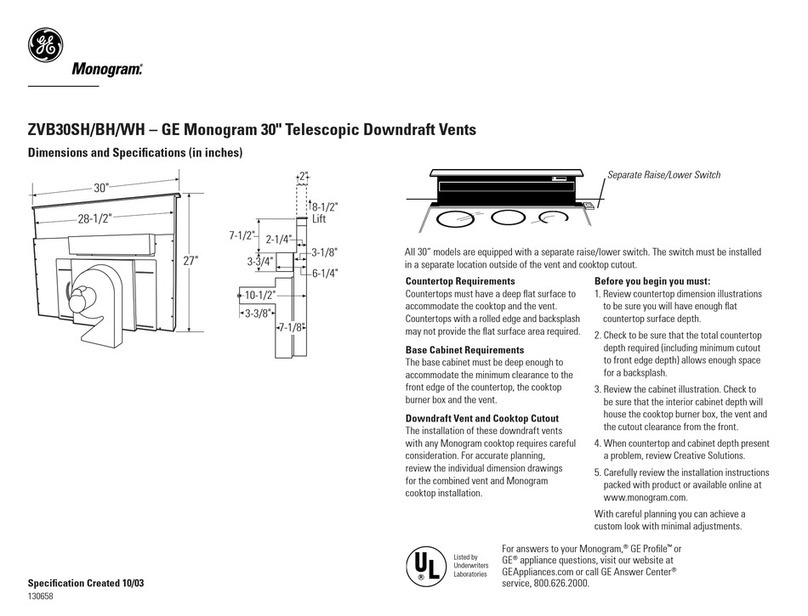

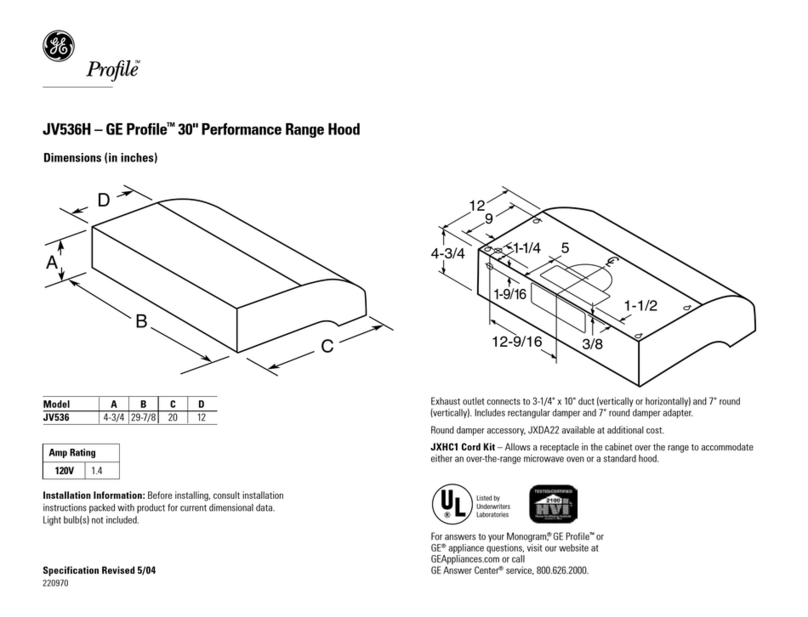

Ductwork Plamah_g

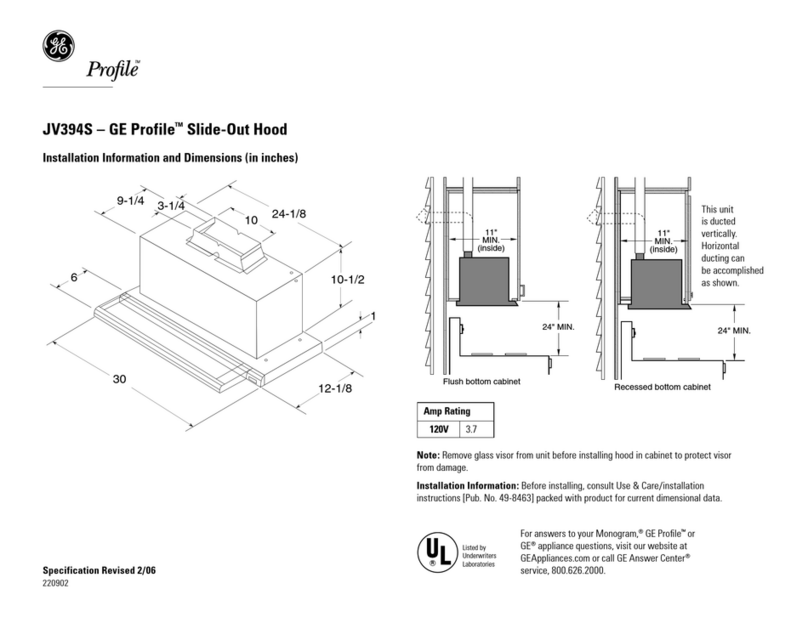

• This hood may be vented vertically through upper

cabinets, soffit or ceiling. A duct transition piece is

supplied fin" vertical exhaust. Use locally supplied

elbows to vent horizontally through the rear wall.

See page 13.

• Determine the exact location of the vent hood,

•Phm tile route fin" venting exhaust to tile outdoors.

• Use tile shortest and straightest duct route possible.

For satislhctm T l)eflbrmance, duct _un should not

exceed 1 O0 tL equivalent length tin" any duct

configurations.

• Refer to "Duct Fittings" chart to compute tile maximmn

permissible length fin" duct itlns to tile outdoors.

• Use metal ductwork only:

• A transition piece fin" 7" rotmd duct is supplied. Lrse

7" round duct or you may use 3-1/4" x 12" rectangular.

• Install a wall cap or roof cap with damper at the

exterior opening. Order tile wall or roof cap and

any transition needed in adwmce.

Kit -JXDW1

Order kitJXDW1 if your installation requires horizontal

ducfing fix)m the top of the hood through the back _Jll and:

•You have an S tL ceiling and need to use a JXCH

Series Chimney Cover, or

•You have a 12" cabinet or 12" sottit that the hood is to

be mo/mted beneath.

Tiffs kit provides a duct transition fl'om 7" to/rod to

3V/' x ] 0" rectangular for through-the-wall venting.

Wall Framhlg for Adequate Support

•This vent hood is heavy. Adequate st_ ucmral sui_port

must be provided. Tile hood must be secured to

vertical studs in the wall. See page 14.

• We strongly recommend that the vent hood with

duct cover be on site befl)re final fl'aming and wall

finishing. This will also hel I) to accurately locate the

ductwork and electrical service.

DUCT FITTINGS

Follow these guidelines fin" proper duct sizing in tile

ductino charts.

DUCTING CHART - 30" Models

Equivalent Length in Feet For 7" RoundDuct

Z 0 25 50 75 100 125 150

600

500

E

400

200 7" Round%° Elbow= 14ft. 7"RoofCap=39ft.

MAXIMUM DUCT LENGTH: 7" dia. duct should not

exceed 100 equivalent feet.

DECORATIVE DUCT COVERS

Adecorative duct cover is available. Tile duct cover

conceals tile ductwork _tmning fl'om tile top of tile

hood to tile ceiling or soffit. Tile duct cover will fit

8 tL to 10 tL ceiling heights. See page 12 tot derails.

POWER SUPPLY

IMP(-)RTANT- (Please read careflfll))

WARNING:

FOIl PERSONAl, SAFETY, THIS APPHANCE MUST

BE PROPERI,Y GROUNDED.

Remoxe house fllse or open circuit breaker before

beginning installation.

Do not use an extension cord or adapter plug with

this appliance. Follow National Electrical Code or

prexailing local codes and ordinances.

Electrical supply

Tiffs vent hood must be suI_plied with 120V, 60Hz, and

cmmected to an individual, properly grounded branch

circuit, and protected by a 15 or 20 amp circuit breaker

or trine delay filse.

• Wiring must be 2 wire with gro/md.

• If the electrical sui)ply does not meet the above

requirements, call a licensed electrician befln'e

proceeding.

• Route house wiring as close to tile installation

location as possible in the ceiling, sottit or wall.

See page 13 fin" details.

• Connect the wiring to the house wiring in

accordance with local codes.

Grounding instructions

Tile gro/mding conductor must be connected to a

gro/mded metal, pemmnent wiring system, or an

equil)ment-grom_ding terminal or lead on tile hood.

WARNING: The improper connection of

tile equii)ment-grounding conductor can result in a

risk of electric shock. Check with a qualified electrician

or service representative if you are in doubt whether

tile appliance is properly gro/mded.