Desi n Information

ADVANCE PLANNING

Remote Switch

The 30" and 36" Monogram models and the 30"

and 36" Profile models have a separate raise/lower

switch. Plan to install the switch in aconvenient

location outside of the vent/cooktop cutout.

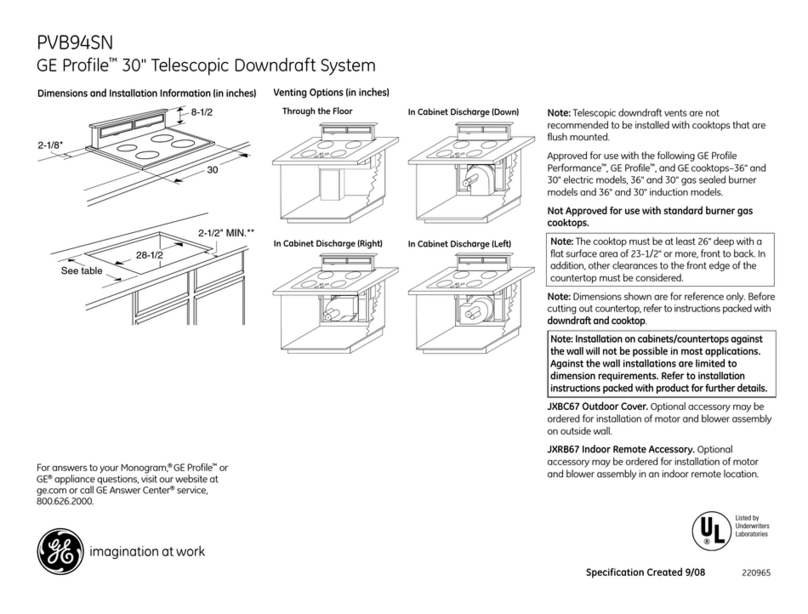

Downdraft Vent and Cooktop Cutout

The installation of these downdraft vents with

any GE or Monogram cooktop requires careful

consideration. Before you begin, review the

combination cutout illustrations on page 6.

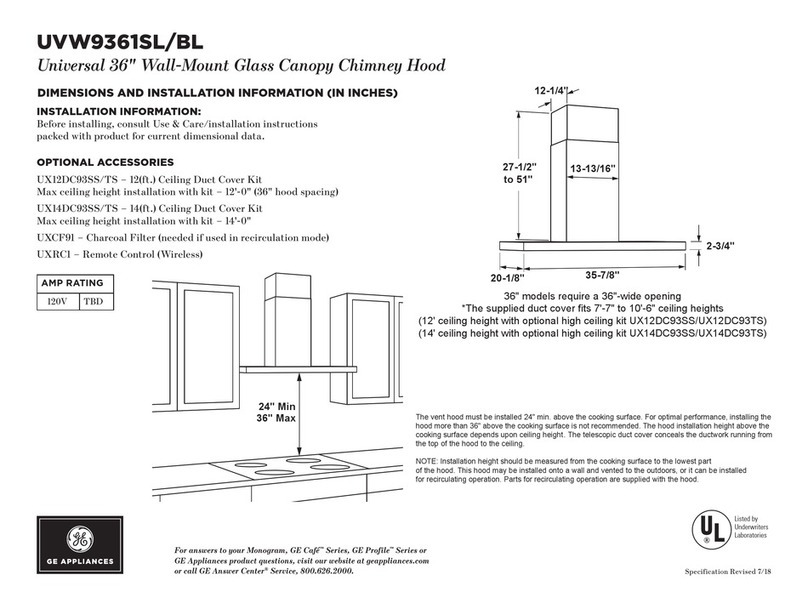

Countertop Requirements

The countertop must have a deep fiat surface

to accommodate the cooktop and the vent.

Countertops with a rolled front edge and backsplash

may not provide the fiat surface area required.

Base Cabinet Requirements

The base cabinet must be deep enough to

accommodate the minimum clearance to the front

of the countertop, the cooktop burner box

and the vent.

Before you begin, you must:

1. Review countertop dimension illustrations to

be sure you will have enough fiat countertop

surface.

2. Check to be sure that the total countertop depth

required (including minimum cutout to front edge

depth) allows enough space for u backsplash.

3. Review the cabinet illustration. Check to be sure

the interior cabinet depth will house the cooktop

burner box, the vent and the cutout clearance

from the front.

°

5.

When countertop and cabinet depth )resent

a problem, review Creative Solutions.

Read this book completely to accurately plan

the installation locution, clearances and

ductwork requirements.

With careful planning, you can achieve a custom

look with minimal adjustments.

Creative Solutions

, When the kitchen design calls for an against-

the-wall installation, move the base cabinet

forward Y' to 5". Filler panels or complementary

moldings can be added to exposed cabinet sides.

, In an island or peninsula, use an extra-deep

countertop. The countertop overhang at the

front can be adjusted to meet setback to cutout

requirements.

. When the cutout to the front edge of the

countertop requirement is more than 2", add

a bullnose trim to the front edge of the

countertop. Include the trim thickness when

measuring the front edge to cutout requirement.

By adding the trim, the cooktop can be moved

forward, providing additional countertop depth

and interior cabinet space.

Maintain Cutout Clearances

to Front Edge as Specified

Filler Panel

Base

Cabinet

Filler Panel

BaseSink

2"

Cover Panel

Countertop

Overhang

per Cooktop

Clearances

Must be

Maintained

_nd

Panel

or OtherDecorative

Molding to Increase

CountertopDepth

andtoMaintain

RequiredClearance

FromFrontEdgeto

Cutout.

4