– 9 –

Using the Liquid Bleach

Dispenser

The bleach dispenser automatically

dilutes and dispenses liquid chlorine

bleach at the proper time in the wash

cycle.

1Check clothing care labels for special

instructions.

2Measure liquid bleach carefully,

following instructions on the bottle.

•Never pour undiluted liquid chlorine

bleach directly onto clothes or into

the wash basket.

•Do not pour powdered bleach into

bleach dispenser. Do not place load

items on top of the bleach dispenser

when loading and unloading the

washer.

•Avoid overfilling or splashing

when adding bleach to the

dispenser. The maximum capacity

of the bleach dispenser is one cup

of bleach per wash cycle. Overfilling

could result in early dispensing of

bleach.

3Before starting the washer, pour

measured amount of bleach directly

into bleach dispenser. If you prefer to

use powdered bleach, add it into the

wash basket directly before adding

clothes.

WARNING!

Do not mix

chlorine bleach with ammonia or acids

such as vinegar and/or rust remover.

Mixing can produce a toxic gas which

may cause death.

The manufacturer’s recommended

amount of undiluted bleach goes into the

bleach dispenser. During the final

“Infusor” wash action, the bleach is added

to the wash load. This ensures

performance won’t be diminished. Two

sequential flushes through the bleach

dispenser completely remove the bleach

from the dispenser. Any residual liquid left

in the dispenser at the end of the cycle is

water, not bleach. To prevent self-

siphoning of the bleach into the wash

basket and damage to your clothes, never

add more than the maximum fill level

marked on the dispenser.

Also keep clothes away from the bleach

dispenser so they don’t absorb any bleach

droplets left around the bleach dispenser.

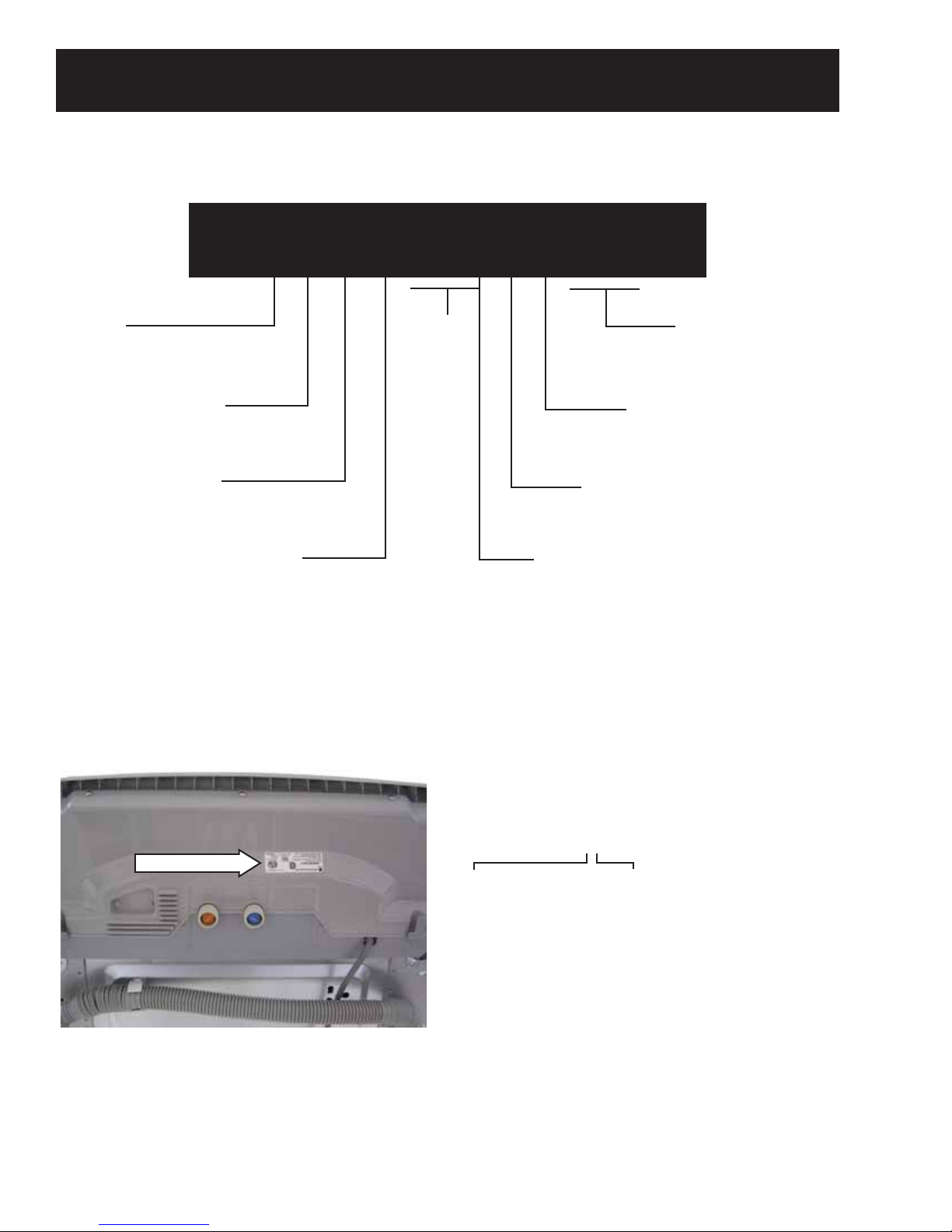

Using the Dispenser Drawer

The dispenser drawer contains

2 compartments:

•Liquid Fabric Softener

• Liquid or Powder Low-Sudsing,

High-Efficiency Detergent

The dispenser automatically dispenses

additives at the proper time in the wash

cycle.

1Slowly open the dispenser drawer by

pulling out the drawer until it stops.

2After adding laundry products, slowly

close the dispenser drawer. Closing the

drawer too quickly could result in early

dispensing of additives.

• Avoid overfilling or splashing when

adding laundry products to the

dispenser. Doing so could result in

early dispensing of laundry products.

At the end of the cycle, you may see

water in the compartments. This is part

of the normal operation of the washer.

NOTE: Do not use bleach in the dispenser

drawer.

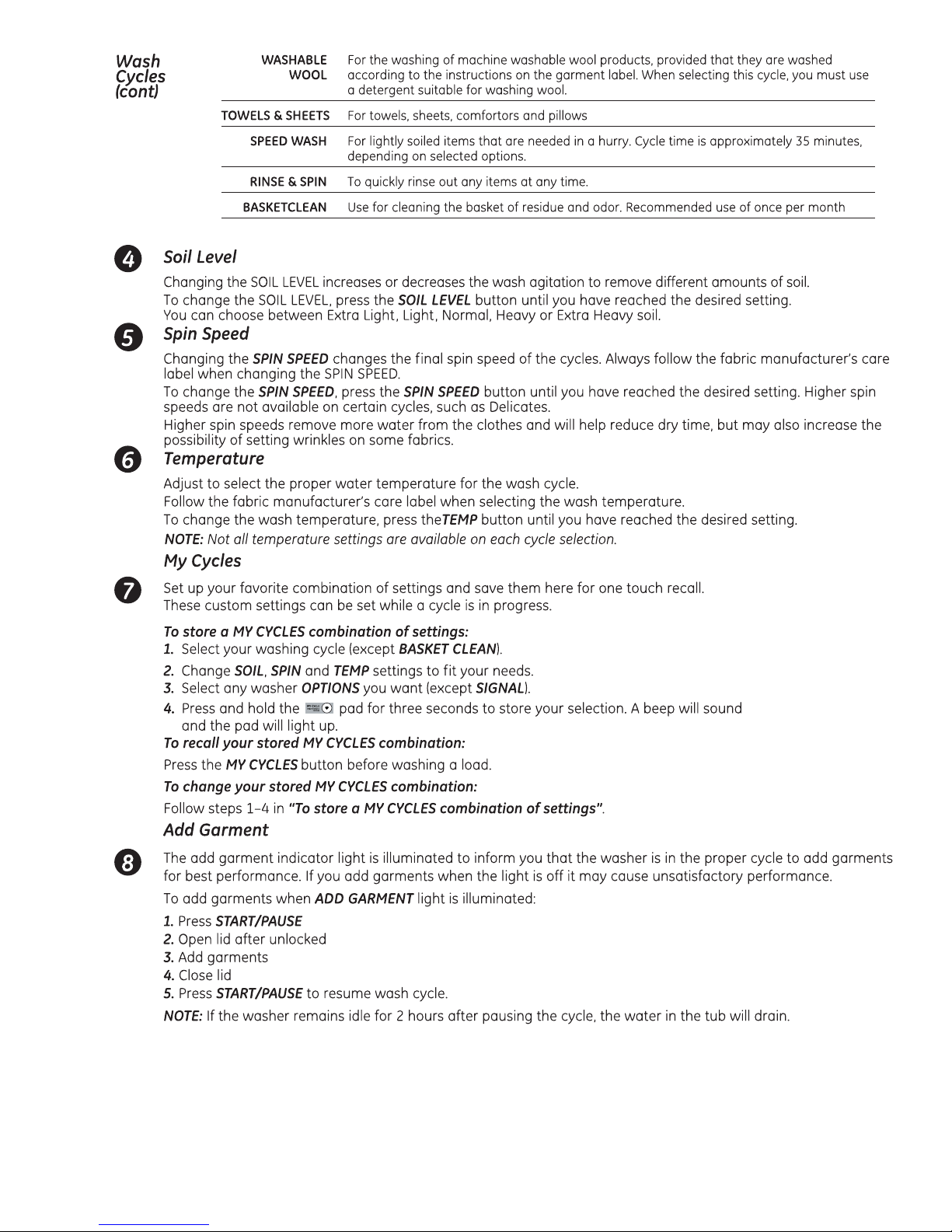

TIDAL WAVE Wash System

Your washer has an innovative washing

system which uses rapid spinning

motion and an angled spray to pull

water through faberic. The TIDAL WAVE

Wash system provides a gentler and

more thorough cleaning.

TIDAL WAVE Wash is avaiable only

during COLORS/NORMAL and

WHITES/HEAVY DUTY cycles.

(Continued Next Page)