3

Table of Contents

Nomenclature……………………………………………………………………….. ……...…………………………....4

Introduction………………………………………………………………………….. …………………………………...5

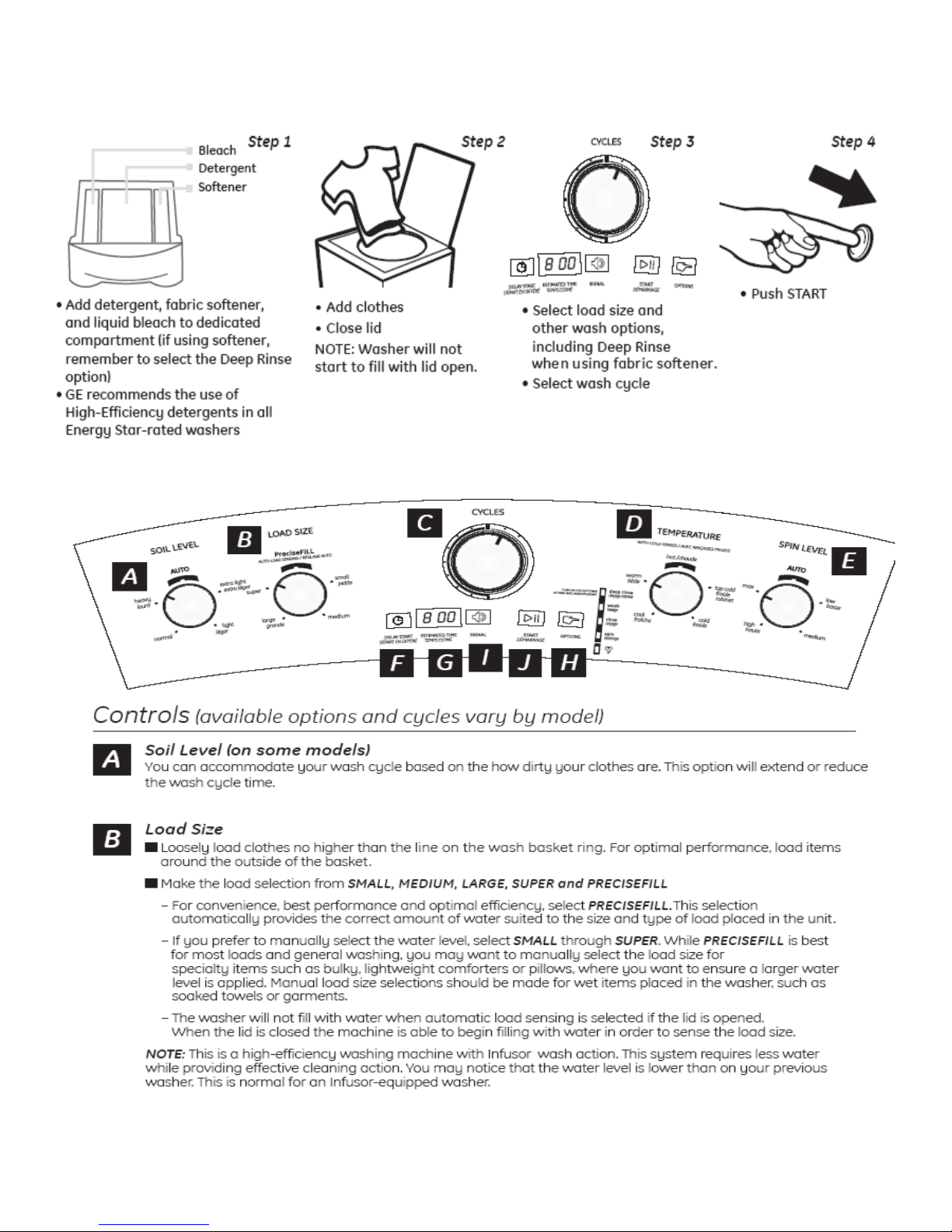

About the control panel…………………………………………………………… ……………………………….6,7,8

Installation…………………………………………………………………………… …………………………………...9

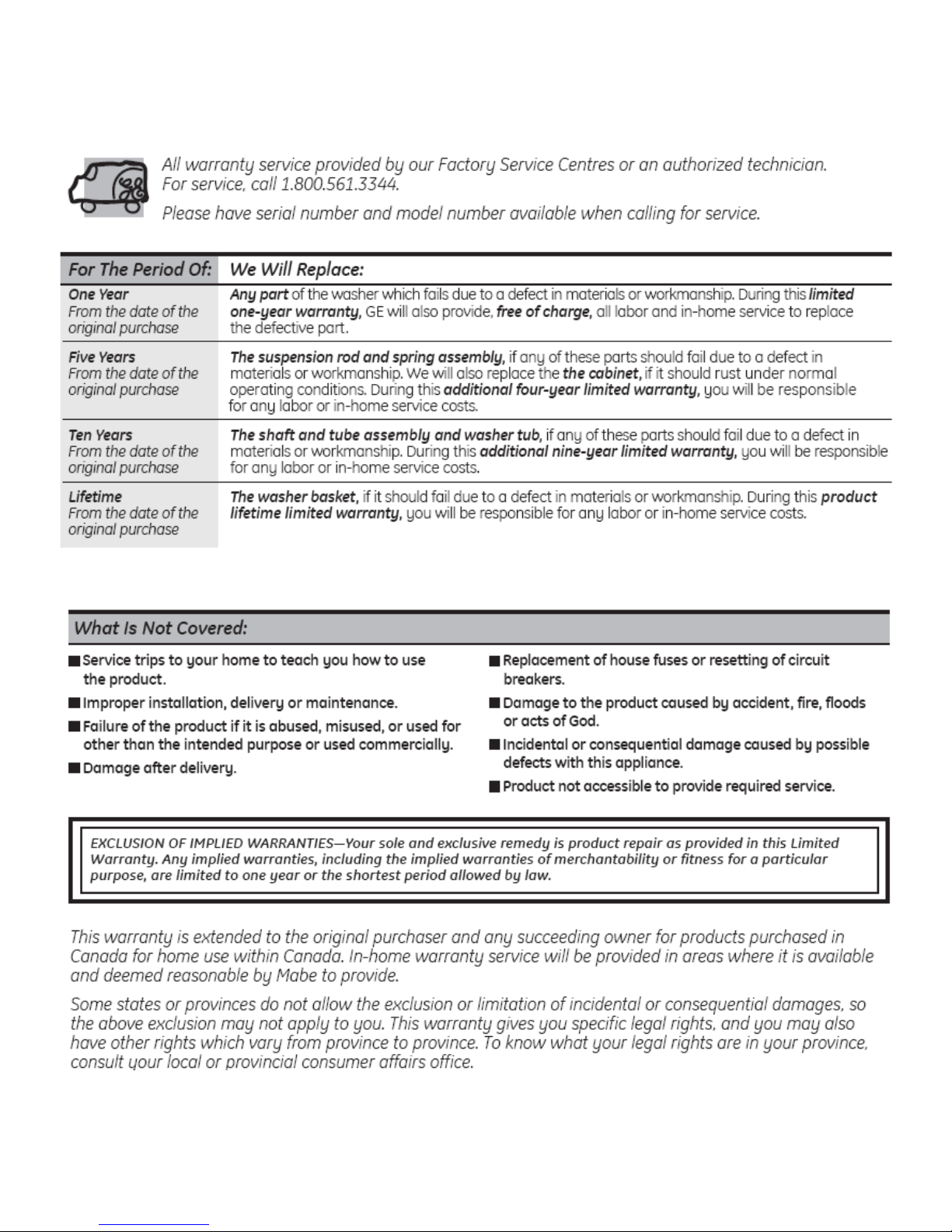

Washer Warranty…………………………………………………………………… ………………………………….10

Drawer dispenser…………………………………………………………………... ………………………………….11

Loading the Washer……………………………………………………………….. ………………………………….12

Water consumption and cycle times……………………………………………. ………………………………….13

HydroSoftTM InfusorTM Washer Tips…………………………………………….. ………………………………….14

Wash Cycle Progression………………………………………………………….. ………………..18, 19, 20, 21, 22

Shower Rinse Progression ………………………………………………………. ………………………………….23

Deep Rinse Progression…………………………………………………………... ………………………………….24

Final Spin…………………………………………………………………………….. ………………………………….25

How to remove the control panel, top, control board ………………………. ……………………………..29, 30

Infusor Removal, transmission removal……………………………………….. …………………….31, 32, 33, 34

ATC Thermistor…………………………………………………………………….. ………………………………….35

Water valves, Drain Pump, Wax Motor, Motor Sensor……………………… ……………………………...36, 37

Testing the Motor…………….…………………………………………………….. ………………………………….38

Shifter System………………………………………………………………………. ………………………………….39

Lid Lock………………………………………………………………………………. …………………….41, 42, 43, 44

How to check the Programs Switch…………………………………………….. ………………………………….45

How to check the Selector Switch……………………………………………… ………………………………….46

Wiring Diagram……………………………………………………………………... ………………………………….47

How to Enter or Exit to Service Mode………………………………………….. ………………………………….48

Component testing (knob position)…………………………………………….. ………………………………….49

Error and Fault Code………………………………………………………………. ………………………………….50

Pressure Sensor……………………………………………………………………. ………………………………….52

Circuit Board Connections……………………………………………………….. ……………………………..53, 54

Understand the consumer’s issue first………………………………………… …………………………15, 16, 17

Operating Cycles…………………………………………………………………… ………………………………….26

Component Locator Views……………………………………………………….. ……………………………..27, 28

Motor Sensor………………………………………………………………………... ………………………………….40

………………………………….51