D

GB

F

E

3

09726-09.2015-DGbF

Contents Page

1 Safety 4

1.1 Identicationofsafetyinstructions

1.2 Qualicationsrequiredofpersonnel

1.3 General safety instructions

1.4 Intended use

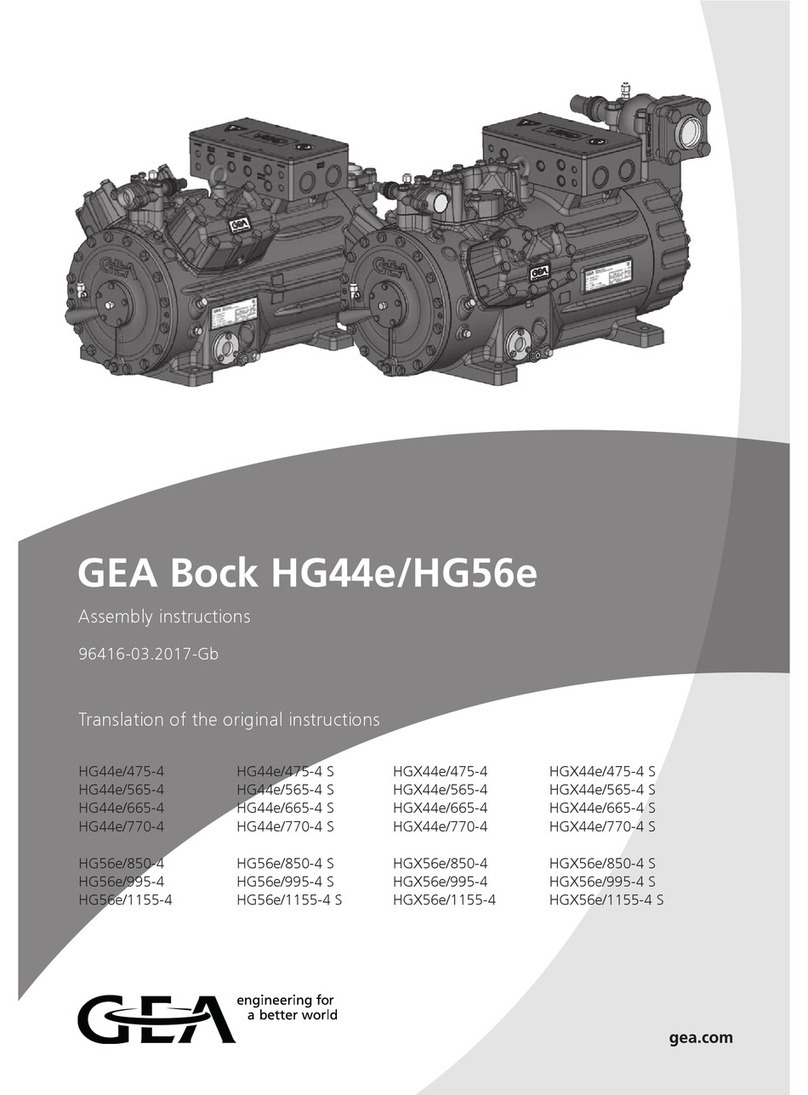

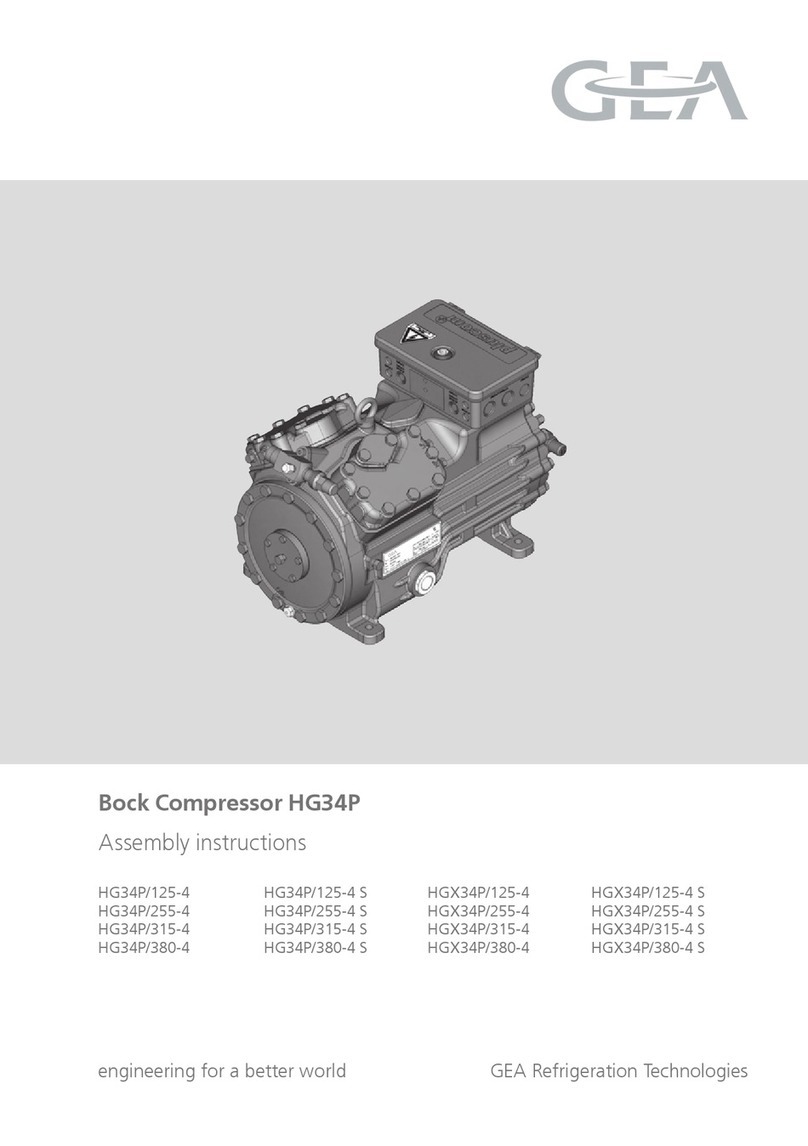

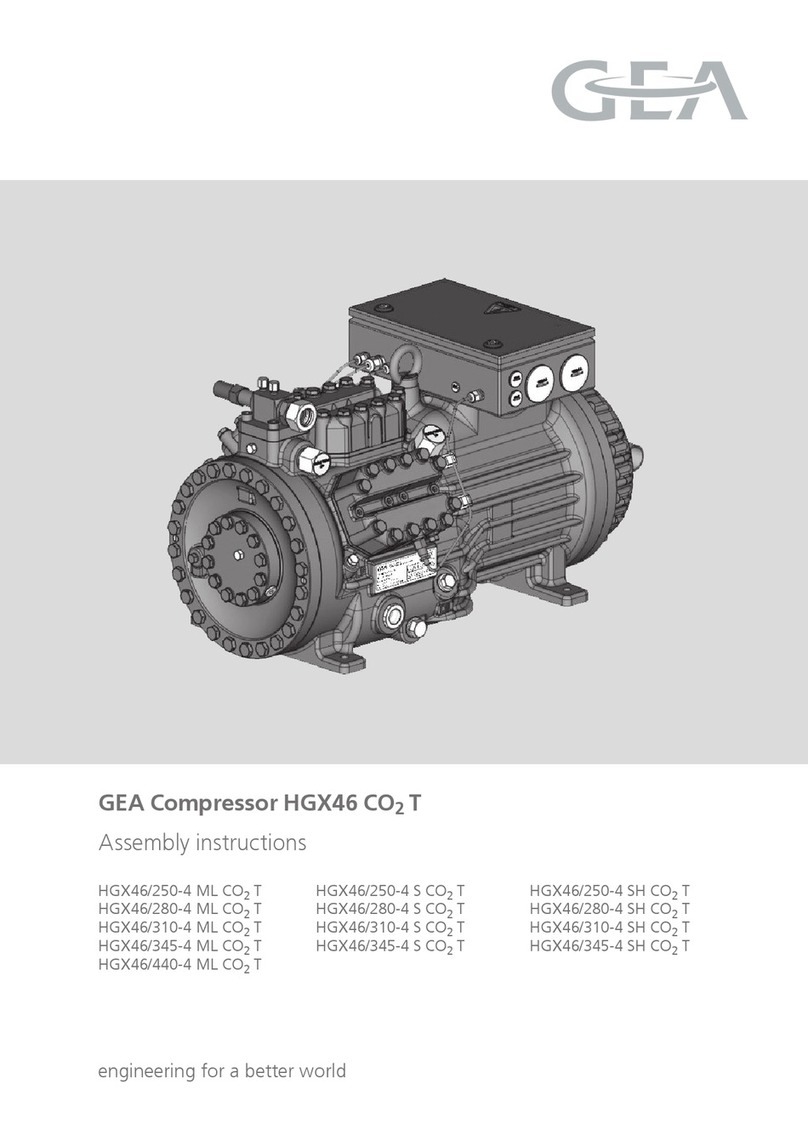

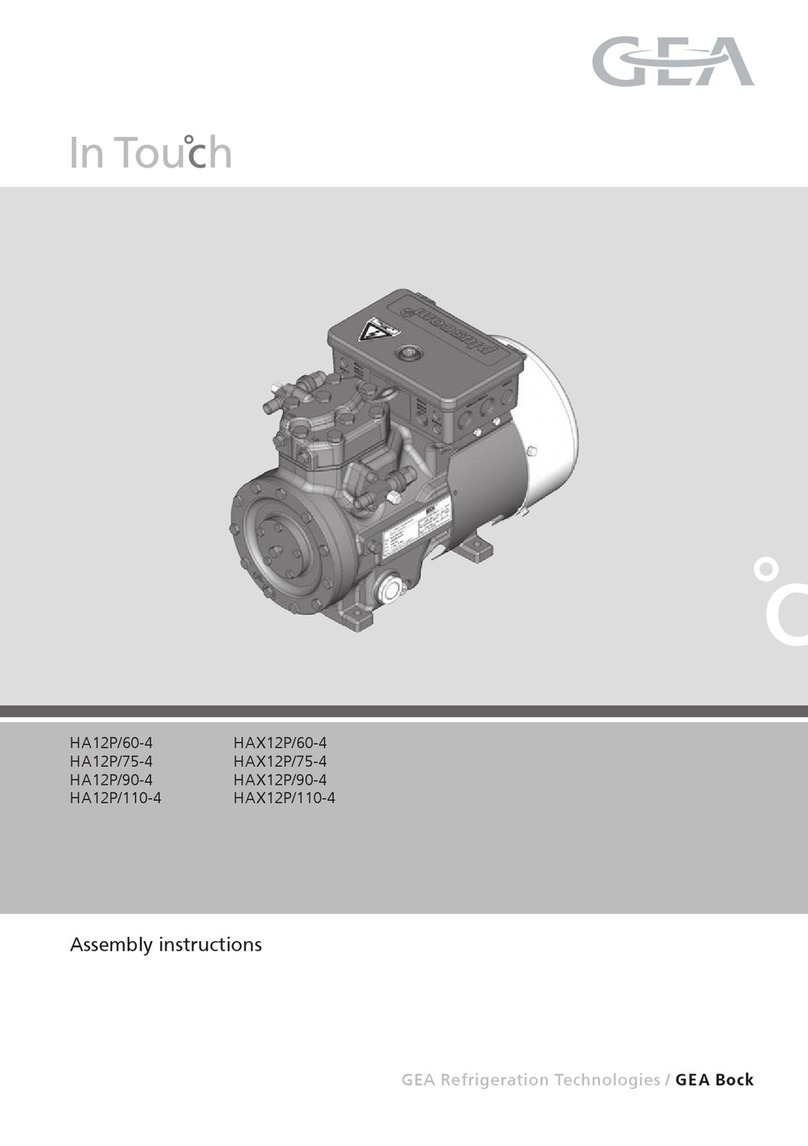

2 Product description 6

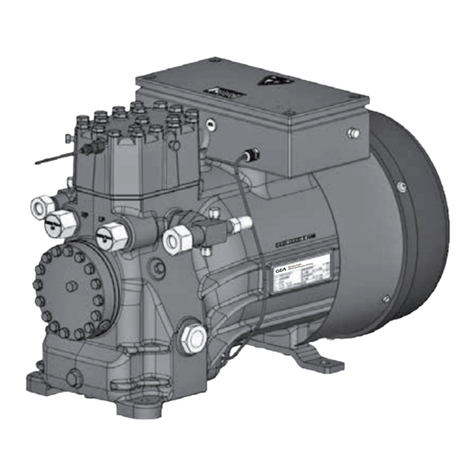

2.1 Short description standard design

2.2 ain and functional parts

2.3 Short description optional design

2.4 Name plate

2.5 Type key

3 Areas of application 9

3.1 Refrigerants

3.2 Oil charge

3.3 Limits of application

3.4

Subcooling temperature

4Description of functions 12

4.1 Two-stagerefrigerationcircuitwithliquidsubcooler

5 Compressor assembly 14

5.1 Storage and transportation

5.2 Setting up

5.3 Installationoftheliquidsubcoolersystem(optionaldesign)

5.4

Installationexample,liquidsubcoolerwithaccessories

5.5 Factory-installedliquidsubcoolersystem(optionaldesign)

5.6 Pipe connections

5.7 Pipes

5.8 Laying suction ans pressure lines

5.9 Operating the shut-off valves

5.10 Operating mode of the lockable service connections

6 Electrical connection 21

6.1 Information for contactor and motor contactor selection

6.2 Circuit diagram for part-winding start

6.3 Standard motor, design for direct or partial winding start

6.4 Electronic trigger unit MP10

6.5 Connecting the trigger unit MP10

6.6 Functional test of the trigger unit MP10

6.7 Oilsumpheater(accessories)

7 Commissioning 28

7.1 Preparations for start-up

7.2 Pressure strengh test

7.3 Leak test

7.4 Evacuation

7.5 Refrigerant charge

7.6 Start-up

7.7 Avoid slugging

8 Maintenance 31

8.1 Preparation

8.2 Work to be carried out

8.3 Spare parts recommendation

8.4 Replacing the valve plates

8.5 Extract from the lubricants table

8.6 Decommissioning

8.7 Accessories

9 Technical data 34

10 Dimensions and connections 35

11 Declaration of conformity and installation 38

12 Service 40