DK50 PLUS, DK50 2V

05/2019 - 1 - NP-DK50 PLUS, 2V-7_05-2019-MD

CONTENTS

IMPORTANT INFORMATION................................................................................................................. 2

CONFORMITY WITH THE REQUIREMENTS OF EUROPEAN UNION DIRECTIVES............ 2

INTENDED USE......................................................................................................................... 2

CONTRAINDICATIONS AND SIDE-EFFECTS.......................................................................... 2

WARNINGS AND SYMBOLS..................................................................................................... 2

WARNINGS................................................................................................................................ 3

STORAGE AND TRANSPORT .................................................................................................. 5

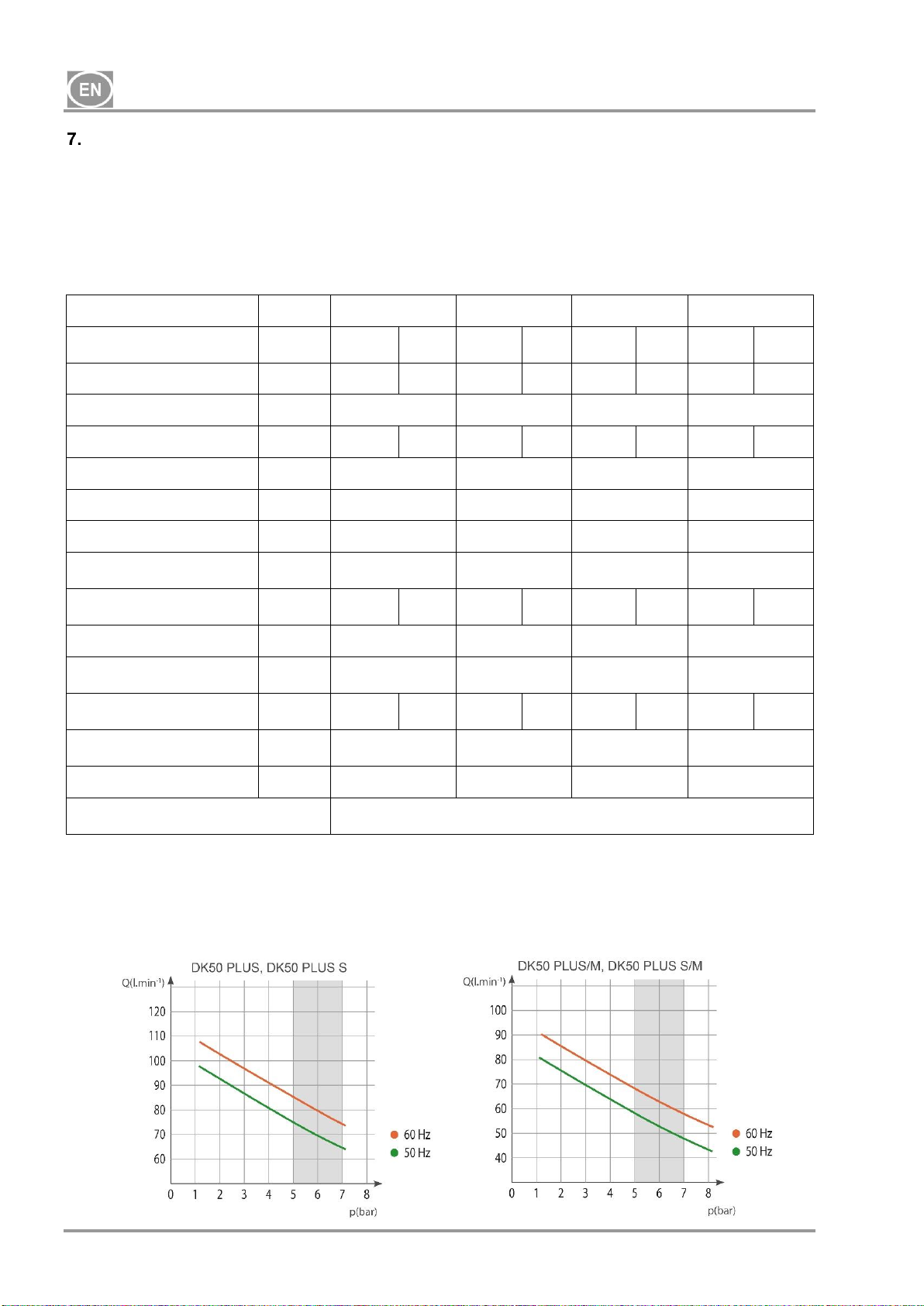

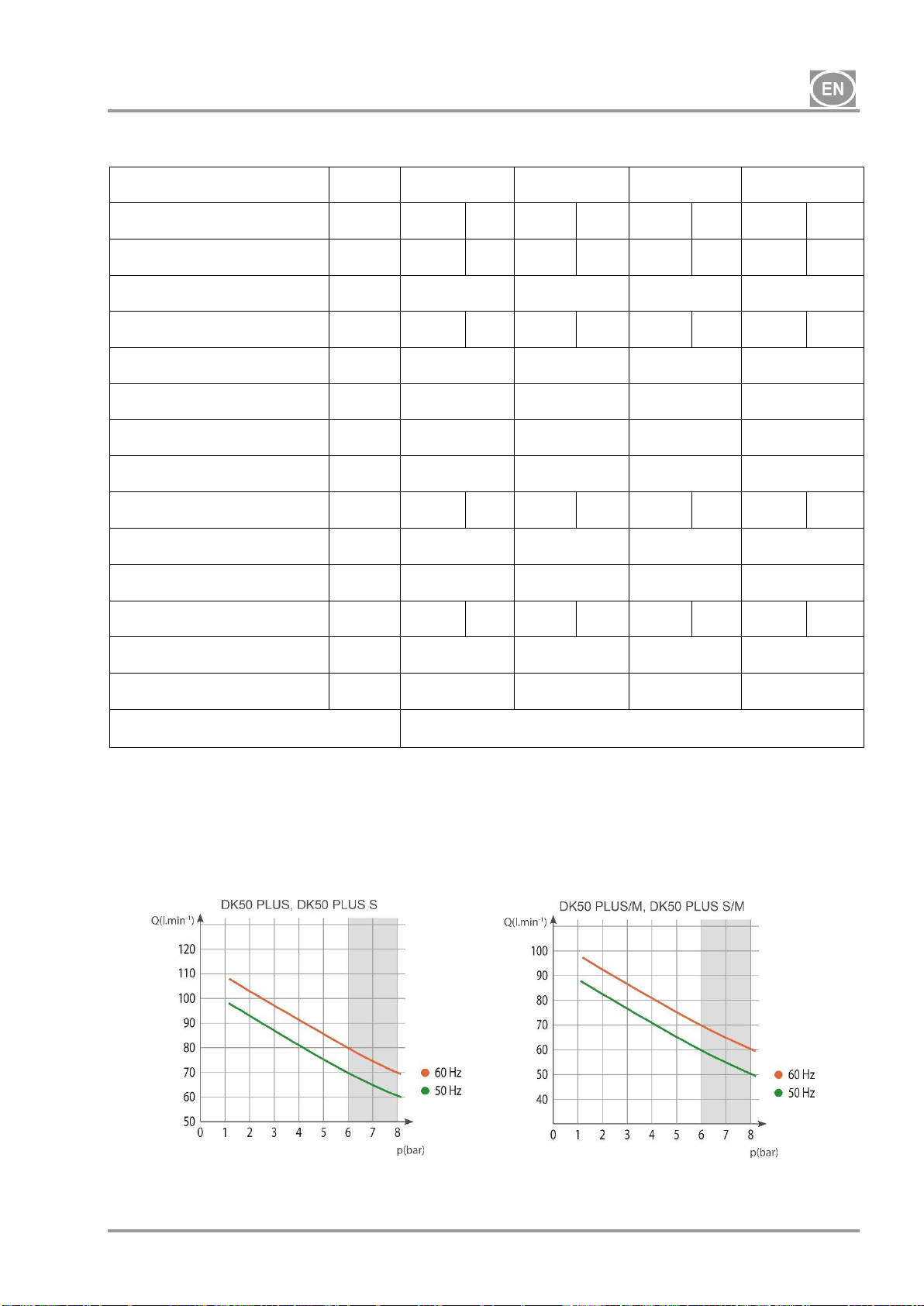

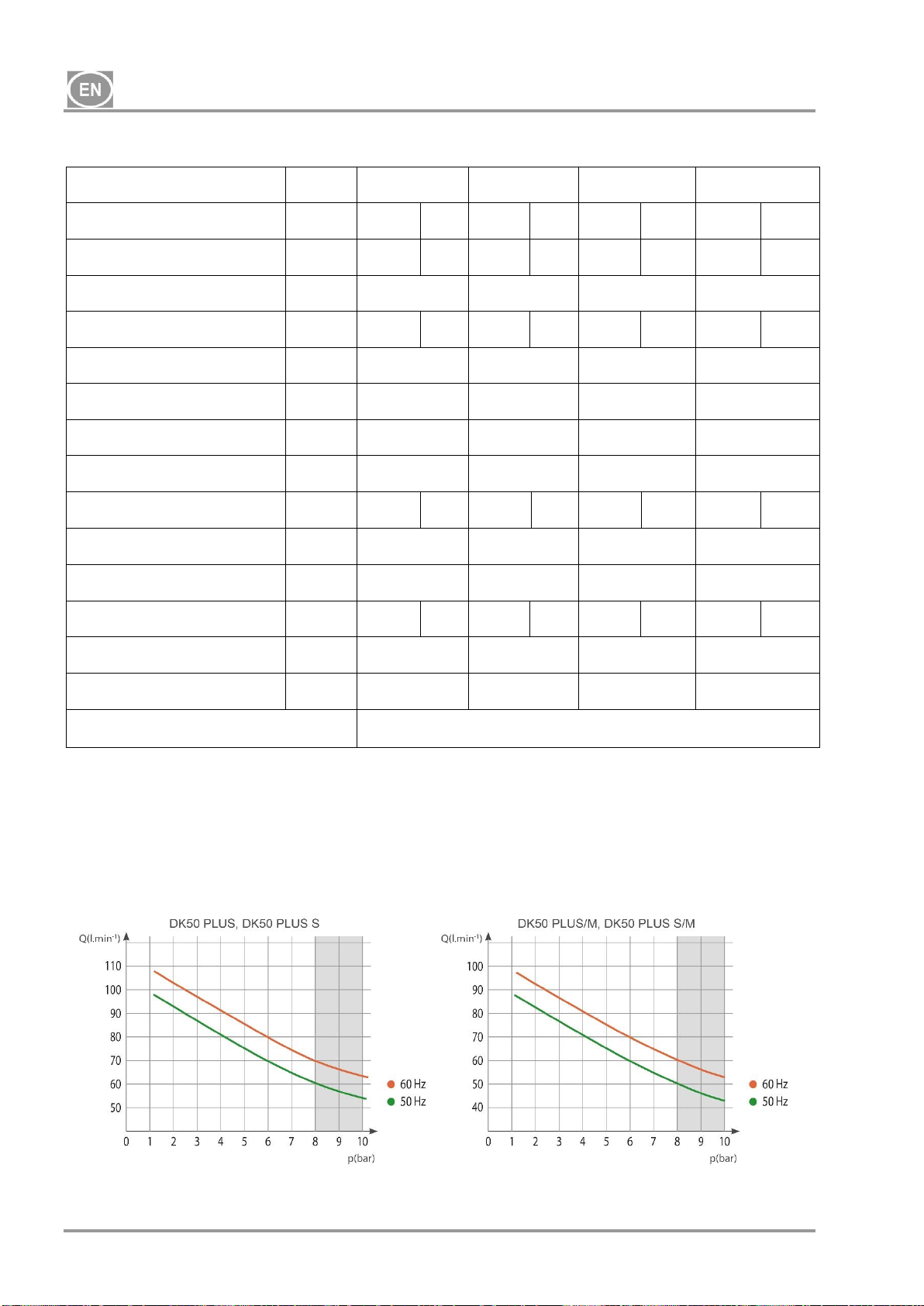

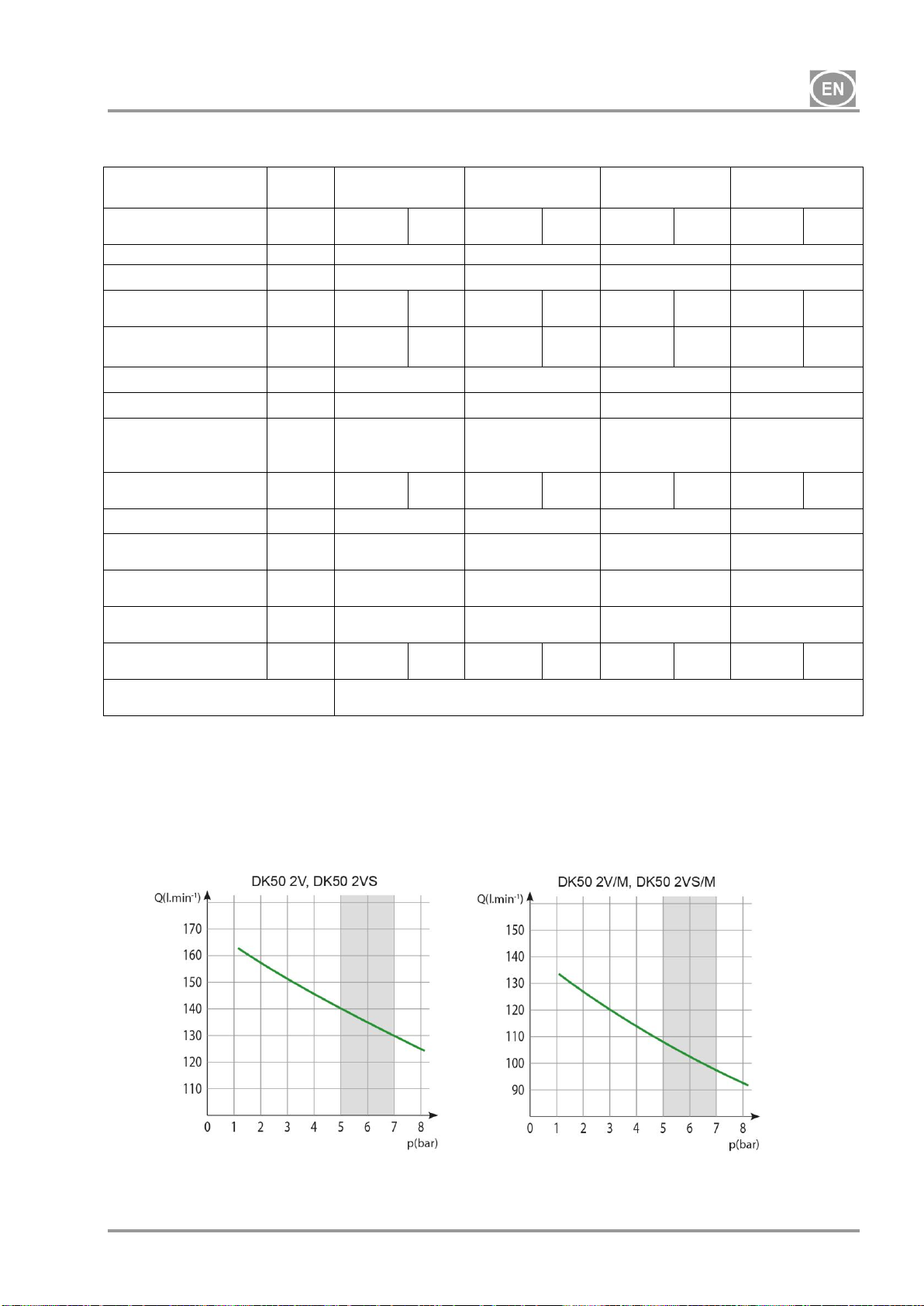

TECHNICAL DATA..................................................................................................................... 6

PRODUCT DESCRIPTION ......................................................................................................15

PRODUCT FUNCTIONALITY .................................................................................................. 16

PNEUMATIC DIAGRAM........................................................................................................... 20

INSTALLATION .................................................................................................................................... 21

CONDITIONS FOR USE .......................................................................................................... 21

PLACEMENT OF THE COMPRESSOR .................................................................................. 22

PNEUMATIC CONNECTIONS................................................................................................ 24

ELECTRICAL CONNECTIONS............................................................................................... 26

CONNECTION DIAGRAM........................................................................................................ 28

OPERATION ......................................................................................................................................... 31

COMMISSIONING....................................................................................................................31

SWITCHING THE COMPRESSOR ON ................................................................................... 32

COMPRESSOR SHUT-DOWN ................................................................................................32

MAINTENANCE.................................................................................................................................... 33

DEVICE MAINTENANCE......................................................................................................... 33

TROUBLESHOOTING.......................................................................................................................... 40

REPAIR SERVICE....................................................................................................................41

STORAGE ................................................................................................................................ 41

DISPOSAL OF THE DEVICE ................................................................................................... 41

ANNEX ................................................................................................................................................ 297

INSTALLATION RECORD...................................................................................................... 297