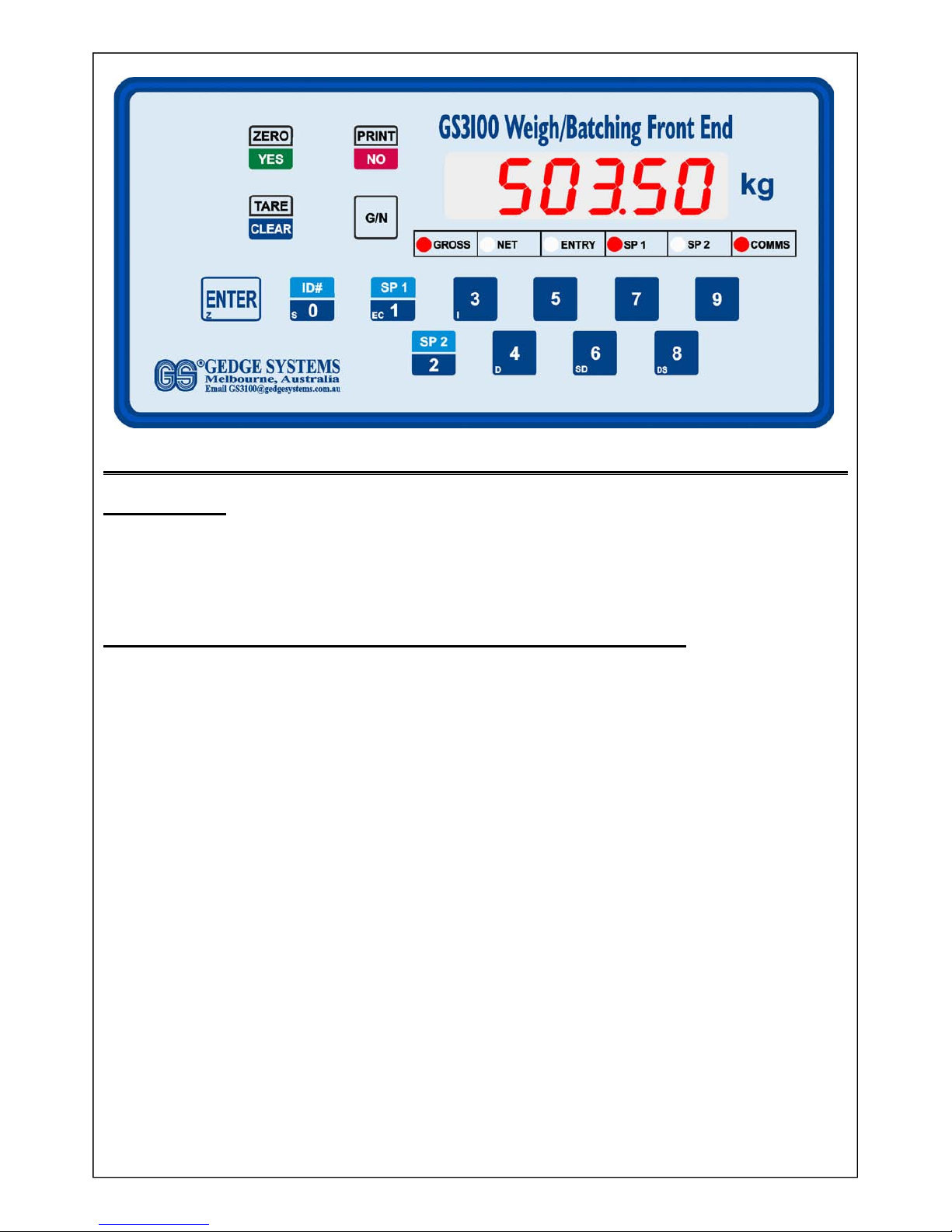

1INTRODUCTION & FEATURES.

The GS3100 is a high performance, high accuracy and high stability microprocessor based digital weight

indicator designed specifically as THE PERFECT Weigh/Batching Front End. The sensible size of the GS3100's

front panel, keyboard and display make it easy to read and use during manual operation and installation. The

very short case length and short cable connectors allow fitment into low cost small enclosures. The GS3100's

wide range of flexible settings will ensure its profitable application in a large number of applications, where it

really shines when used as the input device for Computer/PLC Controlled Batching and Weighing.

The GS3100 includes features NEVER SEEN BEFORE in weight indicators. It sets the benchmark by which

the usefulness of all other indicators used as “front ends” will be judged. Major features and benefits are:-

nNOW AVAILABLE (with version 8A) - Optional High Precision 14bit (1:16,000) 4-20mA and 0-10VDC

Analog Output using OPTION6HPF plus 100% & 0% Load Simulation for external equipment calibration.

nNOW AVAILABLE - MODBUS ASCII and RTU OUTPUT. The factory fitted Option “MODBUS3100"

provides full modbus RTU and ASCII serial I/O from 1200Baud to 19,200Baud with support for

multi-holding register read function 03 and single register write function 06. SLAVE number can be set from

01 to 99. By also selecting Option07 or Option08, users can choose the serial I/O level to suit their

application. Available I/O includes RS-232C; 20mA Current Loop; RS-422A or RS-485 MultiPoint. In

addition, the MODBUS option includes battery backed ram for tare, ID number and zero tracked value.

nNOW AVAILABLE with the release of SOFTWARE VERSION 7 or GREATER - PLC COMPATIBLE 8bit

SERIAL COMMUNICATIONS. You can now easily select the serial word type best suited to your application

- choose either 7bit with Even parity or 8bit with no parity. Word type selection as required by the MODBUS

standard remains fully automatic for MODBUS protocols.

nA World First. The first Digital Weight Indicator to be designed “from the ground up” as a “front end” for

Computer/PLC Controlled batching. It has all of the features and none of the hassles of competing products

which have to be “shoe horned” into the job. It is tailored for the job and fits perfectly.

nComputer/PLCs can talk to “factory floor” operators, via the GS3100, ACROSS the WORLD. The in-built

advanced serial I/O language, using optional serial I/O cards, allows the GS3100's keyboard and display to be

used as the PLC/Computer operator's interface - whether it be on the factory floor or, via a modem, on the

other side of the World. The remotely situated PLC/Computer can completely control the GS3100. In

addition to weight, set point and ID information, it can also request a vast range of information, including

many of the GS3100's installed settings, its product designation, software version and much more.

nSerial I/O Controlled Stream Weight Data Mode. The GS3100's serial I/O language includes commands

which enable the remote Computer/PLC to turn-on and turn-off the GS3100's serial weight stream mode. This

allows the remote Computer to request “high speed” weight data during critical weighing/batching periods

AND to “put to sleep” the GS3100 during periods when high speed weight data is not required.

nGS3100 as the remote Operator input device for the Computer. All front panel key operations can be sent to

the remote Computer. Immediately the Computer puts the GS3100 into “terminal mode”, all operations of the

GS3100's front panel keys are sent to the Computer and not acted upon by the GS3100. During all of this

time, the GS3100 continues weighing and set point operations without interruption.

nGS3100 as a remote message display for the PLC/Computer. Immediately the Computer puts the GS3100 into

“terminal mode”, the GS3100's display is completely under the control of the Computer. It will display any

messages sent to it and so, can be used by the Computer to “talk to” the on-floor operator. During all of this

time, the GS3100 continues weighing and set point operations without interruption.

nStandard “no-extra cost” RS-232 Serial Output. For Computer/PLC controlled applications requiring only

serial weight data, the GS3100 is perfect. Its standard RS-232C 4800/9600 baud output can be programmed

to send weight information, OR, weight information including the status of the alarm set points as well as the

operator ID information.

nFull Range of Programmable Settings. The GS3100's extensive range of keyboard programmable settings

allows it to be “customized” to suit any application. The content of the serial output can be extensively varied

to suit the application. So, too, can the operation of the set points and access to the keyboard functions.