Version

03/11

HYDRAULIC RAIL THREADER

H90461 / NO 10055

TYPE MPR – M

SUMMARY

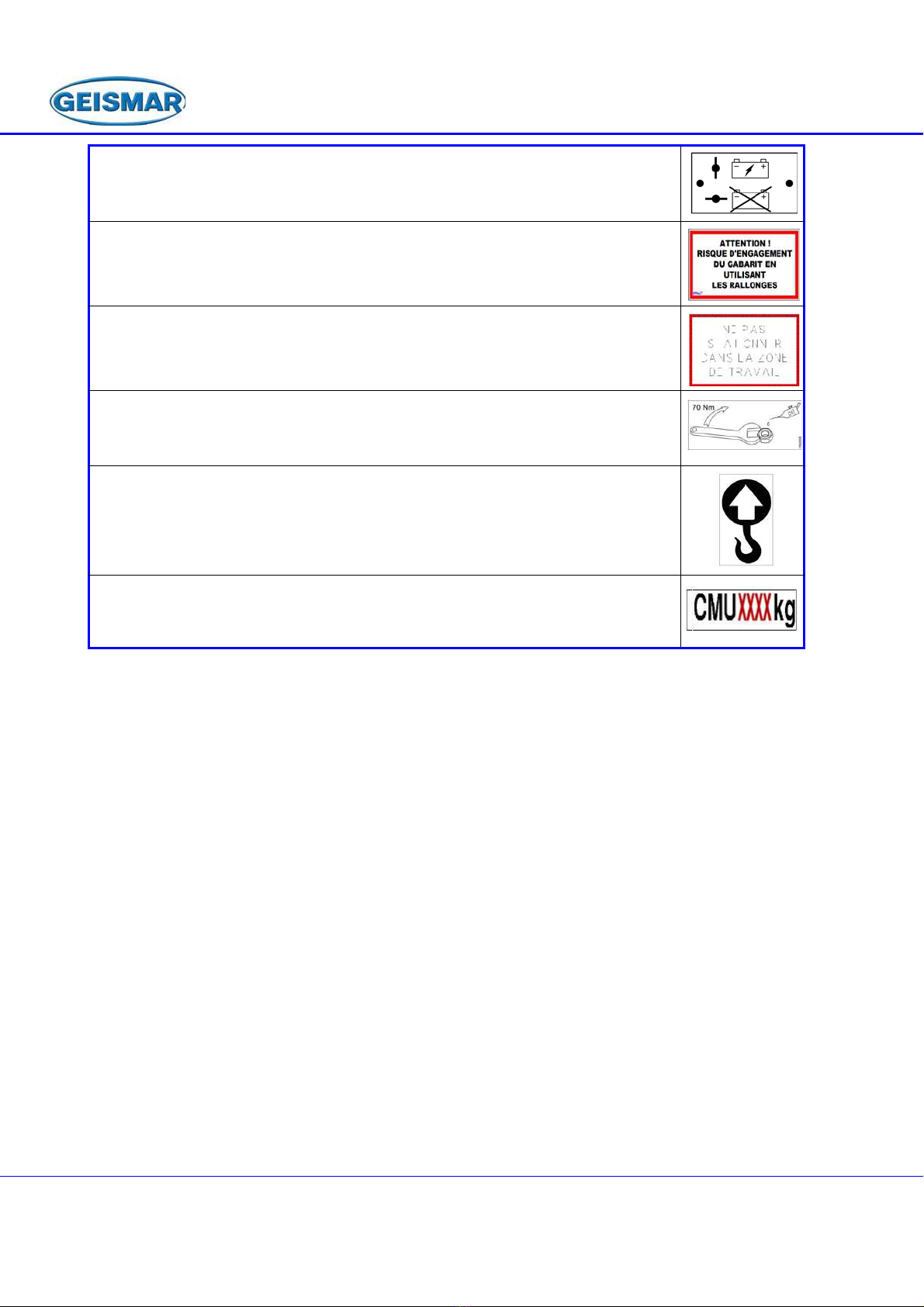

CHAPTER - 1 SAFETY

1 – 1 FOREWORD .........................................................................................................................................................1

1 – 2 WARNING .............................................................................................................................................................2

1 – 3 GENERAL SAFETY INSTRUCTIONS...................................................................................................................2

1 – 3 – 1 T

RANSPORT

– S

TORAGE

................................................................................................................................................ 3

1 – 4 SPECIAL SAFETY INSTRUCTIONS.....................................................................................................................4

1 – 4 – 1 E

QUIPMENT

WITH

A

COMBUSTION

ENGINE

....................................................................................................................... 4

1 – 4 – 2 E

QUIPMENT

WITH

ELECTRICAL

DEVICES

.......................................................................................................................... 4

1 – 4 – 3 E

QUIPMENT

WITH

HYDRAULIC

DEVICES

........................................................................................................................... 4

1 – 4 – 4 L

IFTING

EQUIPMENT

....................................................................................................................................................... 5

CHAPTER - 2 PRESENTATION

2 – 1 GENERAL PRESENTATION.................................................................................................................................7

2 – 2 GENERAL INFORMATION ...................................................................................................................................8

CHAPTER - 3 TECHNICAL CHARACTERISTICS

3 – 1 GENERAL CHARACTERISTICS...........................................................................................................................9

3 – 2 DIMENSIONS OF THE RAIL THREADER..........................................................................................................11

3 – 3 LOCATION IN LOADING CLEARANCE..............................................................................................................12

CHAPTER - 4 EQUIPMENTS

4 – 1 LOCATION OF THE MAIN UNITS ......................................................................................................................13

4 – 2 HYDRAULIC UNIT...............................................................................................................................................14

4 – 4 HYDRAULIC CONTROLS...................................................................................................................................15

4 – 5 MOTORISED TROLLEYS ...................................................................................................................................16

4 – 5 – 1 T

RAVEL

TROLLEY

......................................................................................................................................................... 17

4 – 6 MAIN FRAME ......................................................................................................................................................19

4 – 7 ELETRICAL UNIT................................................................................................................................................21

4 – 7 – 1 E

LECTRICAL

ENCLOSURE

............................................................................................................................................. 21

4 – 7 – 2 B

ATTERY

COMPARTMENT

............................................................................................................................................. 22

4 – 7 – 3 L

INING

T

RACK

............................................................................................................................................................. 23

CHAPTER - 5 OPERATING INSTRUCTIONS

5 – 1 HANDLING INSTRUCTIONS ..............................................................................................................................25

5 – 2 PREAMBLE .........................................................................................................................................................25

5 – 2 – 1 R

EMINDER

OF

TERMS

USED

IN

THIS

CHAPTER

............................................................................................................... 25