GEM A/Q-71 User manual

HOR. SIDEWALL & RECESSED HOR. SIDEWALL SPRINKLERS

UNIVERSAL MODEL A/Q-71

QUICK RESPONSE, 3 mm BULB TYPE, 5.6 K-FACTOR, 1/2" NPT**

GENERAL DESCRIPTION

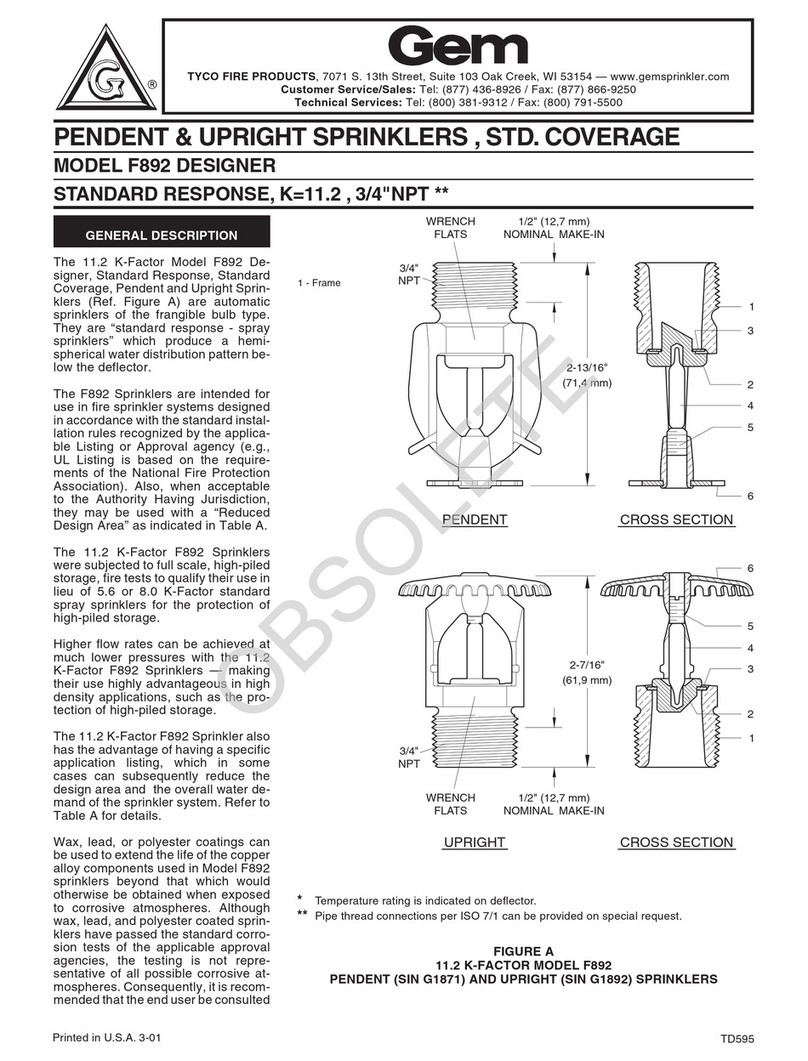

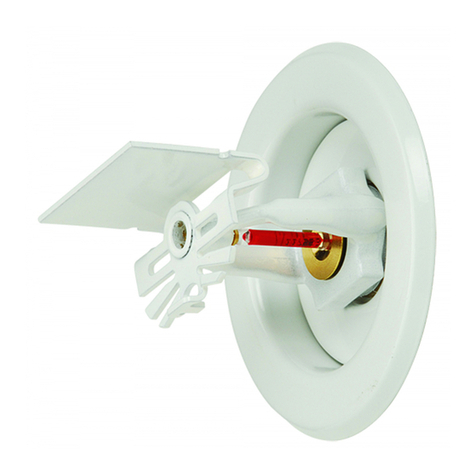

The 5.6 K-Factor Quick Response Uni-

versal Model A/Q-71 Horizontal Side-

wall and Recessed Horizontal Side-

wall Sprinklers (Ref. Figure A) are

automatic sprinklers of the “quick re-

sponse” frangible bulb type. They are

“standard spray sprinklers” intended

for use in fire sprinkler systems de-

signed in accordance with the stand-

ard installation rules recognized by the

applicable Listing or Approval agency

(e.g., UL Listing is based on NFPA 13

requirements).

Horizontal sidewall sprinklers are gen-

erally used in lieu of pendent and up-

right sprinklers because of building

construction or installation economy

considerations. They are designed for

installation along a wall or side of a

beam and just beneath a smooth ceil-

ing. Installed with their centerline of

waterway horizontal, these sprinklers

produce a quarter-spherical water dis-

charge pattern that is predominately

directed downward and outward from

the deflector; however, a portion of the

spray is also directed towards the back

wall.

The Model A/Q-71 Sprinklers feature a

unique “Deflector Hat” which provides

a low profile for improved aesthetics.

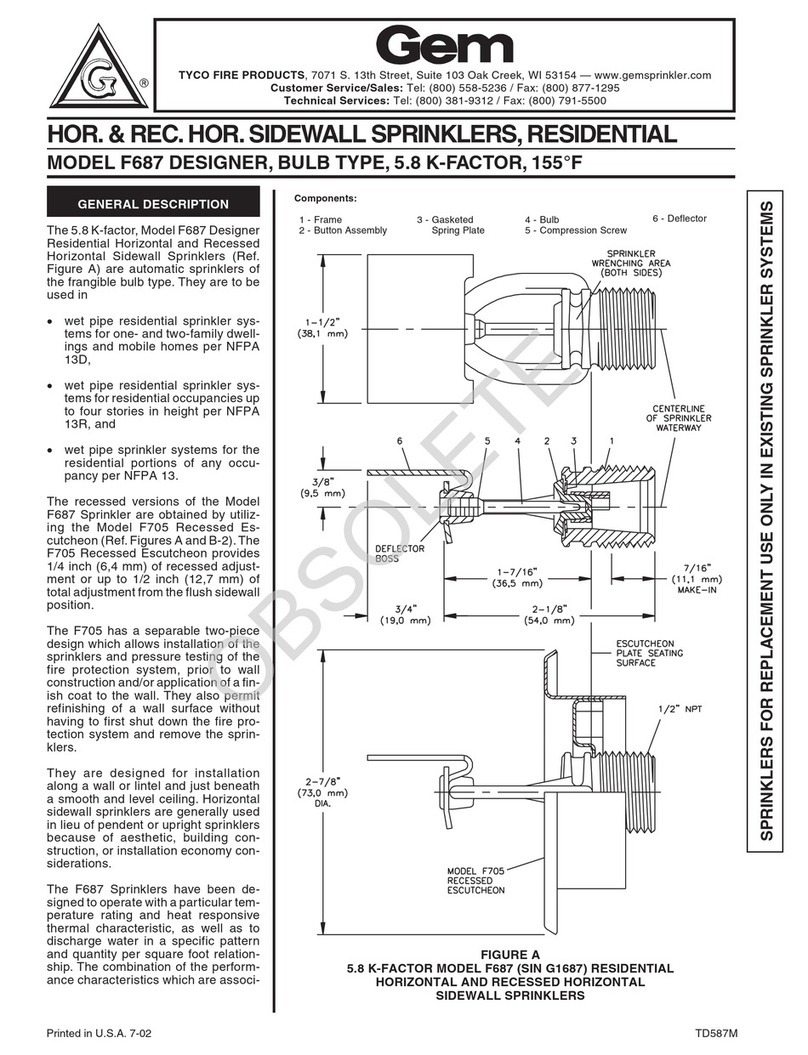

The recessed versions of the Model

A/Q-71 Sprinkler are obtained by util-

izing the Model A/Q-71 Sprinkler in

combination with either the Model

F700 or F705 Recessed Escutcheon

(Ref. Figures A and B). The F700 and

F705 Recessed Escutcheons have a

separable two-piece design which al-

lows installation of the sprinklers and

pressure testing of the fire protection

system, prior to wall construction

and/or application of a finish coat to

the wall. They also permit refinishing

of a wall surface without having to first

shut down the fire protection system

and remove the sprinklers.

The vertical adjustment provided by

the F700 or F705 substantially re-

duces the accuracy to which the length

of fixed pipe nipples to the sprinklers

must be cut. Also, the Closure has a

1/2 inch (12,7 mm) wide flange which

provides ample clearance for covering

the mounting hole.

Lead coatings are utilized to extend

the life of copper alloy sprinklers be-

yond that which would otherwise be

obtained when exposed to corrosive

atmospheres. Although lead coated

sprinklers have passed the standard

corrosion tests of the applicable ap-

proval agencies, the testing is not rep-

resentative of all possible corrosive at-

mospheres. Consequently, it is

recommended that the end user be

consulted with respect to the suitability

Printed in U.S.A. 3-01 TD534

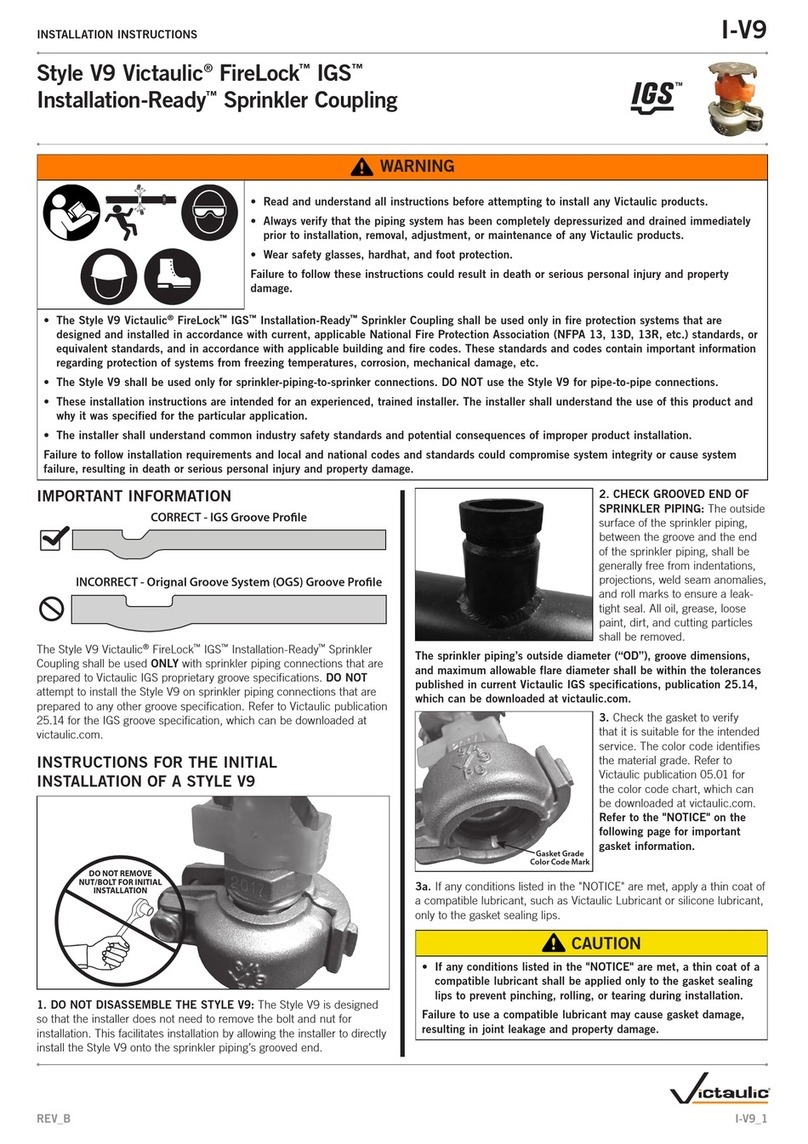

FIGURE A

5.6 K-FACTOR QUICK RESPONSE

MODEL A/Q-71 HORIZONTAL SIDEWALL (SIN G7378) SPRINKLERS

1 - Frame

2-Button

3 - Gasketed

Spring

Plate

4 - Bulb

5 - Compression

Screw

6 - Deflector

*Temperature rating is indicated on deflector or adjacent to orifice seat on frame.

** Pipe thread connections per ISO 7/1 can be provided on special request.

24

5

PLATE SEATING

ESCUTCHEON

(11,1 mm)

NOMINAL

MAKE-IN

SURFACE

13

**

2-7/8" DIA.

ESCUTCHEON

F700 or F705

RECESSED

(73,0 mm)

WRENCH

FLATS

1-1/2"

(38,1 mm)

2-3/16"

(55,6 mm)

7/16"

1-13/16"

(46,0 mm)

MODEL

HAT

DEFLECTOR

1/2"

NPT

6

CENTERLINE

WATERWAY

OF SPRINKLER

*

9/16"

(14,3 mm)

TYCO FIRE PRODUCTS, 7071 S. 13th Street, Suite 103 Oak Creek, WI 53154 — www.gemsprinkler.com

Customer Service/Sales: Tel: (877) 436-8926 / Fax: (877) 866-9250

Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500

OBSOLETE

of these corrosion resistant coatings

for any given corrosive environment.

The effects of ambient temperature,

concentration of chemicals, and

gas/chemical velocity, should be con-

sidered, as a minimum, along with the

corrosive nature of the chemical to

which the sprinklers will be exposed.

APPROVALS AND STANDARDS

Laboratory listings and approvals for

the 5.6 K-Factor Model A/Q-71 Hori-

zontal Sidewall Sprinklers and Re-

cessed Horizontal Sidewall Sprinklers

are given in Table A.

WARNING

The 5.6 K-Factor Model A/Q-71 Hori-

zontal Sidewall Sprinklers and Re-

cessed Horizontal Sidewall Sprin-

klers described herein must be

installed and maintained in compli-

ance with this document, as well as

applicable standards of the National

Fire Protection Association, in addi-

tion to the standards of any other

authorities having jurisdiction. Fail-

ure to do so may impair the integrity

of these devices.

The owner is responsible for main-

taining their fire protection system

and devices in proper operating con-

dition. The installing contractor or

manufacturer should be contacted

relative to any questions.

Installation of Model A/Q-71 Hori-

zontal Sidewall Sprinklers in re-

cessed escutcheons other than the

F700 or F705 will void all sprinkler

warranties, as well as possibly void

the sprinklers Approvals and/or

Listings.

TECHNICAL DATA

The 5.6 K-Factor Model A/Q-71 Hori-

zontal Sidewall Sprinklers and Re-

cessed Horizontal Sidewall Sprinklers

are rated for use at a maximum service

pressure of 175 psi (12,1 bar). They

are to be installed in accordance with

the deflector-to-ceiling distance speci-

fications indicated in Table A, and the

standard rules recognized by the ap-

plicable Listing or Approval agency.

The sprinklers are available in the tem-

perature ratings and finishes indicated

in Table A.

The nominal flow “Q” in GPM (LPM) is

determined by the following formula:

where the nominal discharge coeffi-

cient “K” equals 5.6 (80,7) and “p”

equals the residual flowing pressure in

psi (bar).

The Frame of the Model A Sprinkler

(Ref. Figure A), is a dezincification re-

sistant bronze, and the Deflector is

brass. The Button and Compression

Screw are bronze. The Gasketed

Spring Plate consists of a beryllium

nickel disc spring that is sealed on

both its inside and outside faces with

a Teflon

gasket. The quick response

Model A/Q-71 Sprinklers utilize a 3

mm diameter frangible bulb. Table A

indicates the bulb liquid color as a

function of temperature rating.

NOTES

Inquiries concerning the appropriate-

QKp

=

DuPont Registered Trademark

TYPE TEMPERATURE

RATING

BULB

LIQUID

COLOR

NATURAL

BRASS

CHROME

PLATED

POLYESTER

COATED

(All Colors)

135°F/57°C

155°F/68°C

175°F/79°C

200°F/93°C

286°F/141°C

HORIZONTAL

SIDEWALL

(G7378)

SPRINKLER FINISH

Orange

Red

Yellow

Green

Blue

RECESSED

HORIZONTAL

SIDEWALL

(G7378)

WITH

F700

135°F/57°C

155°F/68°C

175°F/79°C

200°F/93°C

Orange

Red

Yellow

Green

NOTES:

1. Listed by Underwriters Laboratories, Inc. as Quick Response Sprinklers for use in Light and Ordinary Hazard Occupancies.

2. Listed by Underwriters’ Laboratories of Canada as Quick Response Sprinklers for use in Light and Ordinary Hazard Occupancies.

3. Approved by Factory Mutual Research Corporation as Quick Response Sprinklers for use in Light Hazard Occupancies.

4. Approved by the Loss Prevention Council (United Kingdom). The LPC does not rate the thermal sensitivity of horizontal sidewall

sprinklers.

5. Approved by the Scientific Services Laboratory (Australia) as Quick Response Sprinklers.

6. Accepted by the City of New York under MEA 241-94-E as Quick Response Sprinklers.

7. UL and ULC Listings, as well as FM, SSL, and NYC Approvals, are based on a deflector-to-ceiling distance of 4 to 12 inches (100 to

300 mm), whereas LPC Approval is based on 4 to 6 inches (100 to 150 mm). The top of the Deflector Hat, to which these dimensions

apply, is 9/16 inch (14.3 mm) above the centerline of waterway (Ref, Figure A).

N/A: Not Available

TABLE A

LABORATORY LISTINGS AND APPROVALS

(See Note 7 Above)

LEAD

COATED

N/A

1, 2, 3

1, 2, 4, 5, 6

1, 2, 3, 4, 5, 6

RECESSED

HORIZONTAL

SIDEWALL

(G7378)

WITH

F705

135°F/57°C Orange

1, 2, 3, 4, 5, 6 N/A

155°F/68°C Red

Yellow175°F/79°C

200°F/93°C Green

OBSOLETE

ness of lead coated sprinklers for a

given corrosive environment should

be submitted to the attention of the

Technical Services Department.

Lead coated sprinklers are not suit-

able for use in open sprinkler applica-

tions.

INSTALLATION

NOTES

Do not installany bulb sprinkler if the

bulb is cracked or there is a loss of

liquid from the bulb. With the sprin-

kler held horizontal, a small air bub-

ble should be present. The diameter of

the air bubble is approximately 1/16

inch (1,6 mm) for the 135°F/57°C to

3/32 inch (2,4 mm) for the

286°F/141°C temperature rating.

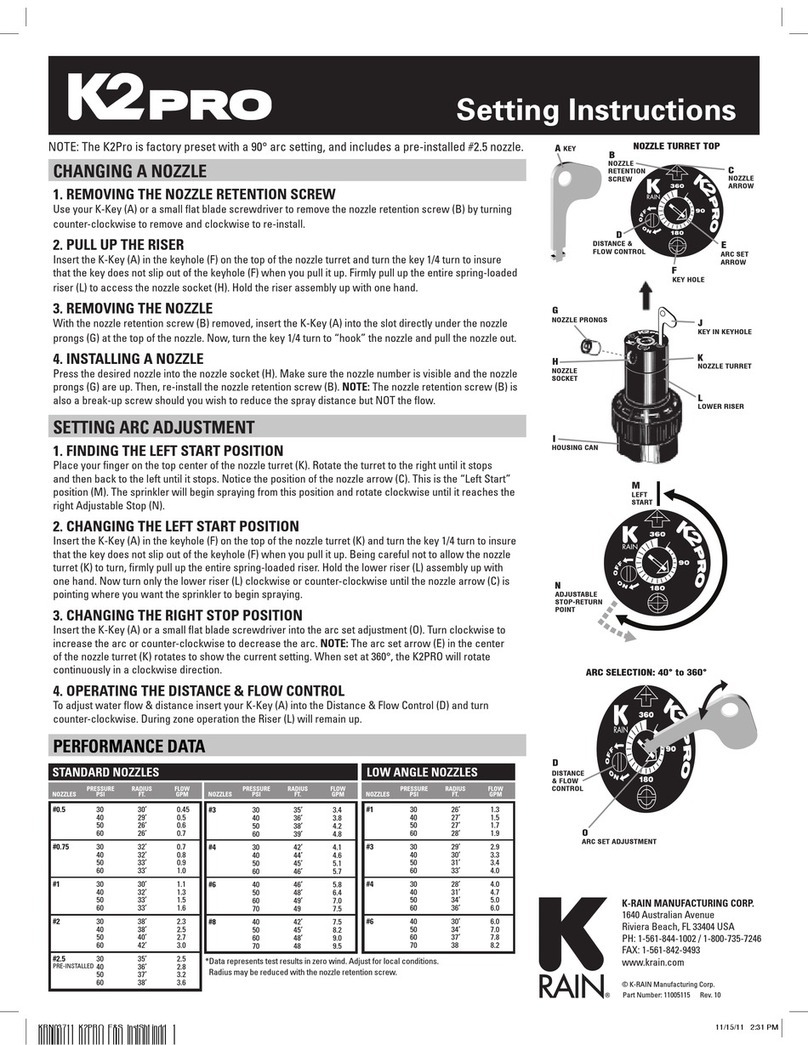

FIGURE B

MODEL A/Q-71 RECESSED HORIZONTAL SIDEWALL SPRINKLER

WITH TWO-PIECE MODEL F700 AND F705 RECESSED ESCUTCHEON

Dim. Inches MM

A- 5/8±1/8†† 15,9±3,2

B-Min. 3/4 19,1

B-Nom. 1 25,4

B-Max. 1-1/4 31,8

C-Min. 1/4 6,4

C-Max. 3/4 19,1

FULLY RECESSED

DIMENSIONS†

Up to 1/2 inch adjustment from

minimum 1/4 inch to maximum

3/4 inch recessed position.

HIGH ADJUSTMENT

DIMENSIONS

Up to 3/4 inch adjustment from

the flush ceiling position to 3/4

inch recessed position.

Dim. Inches MM

A- 1/2±1/4†† 12,7±6,4

B-Min. 3/4 19,1

B-Nom. 1-1/8 28,6

B-Max. 1-1/2 38,1

C-Min. FLUSH —

C-Max. 3/4 19,1

† For best overall

appearance.

†† Remaining 1/4 inch (6,4

mm) of adjustment can

be used to compensate

for variations in

sprinkler make-in and

fitting take-out.

1- Model A/Q-71 Horizontal

Sidewall Sprinkler

2- Model F700 or F705

Recessed

Escutcheon

a- Mounting Plate

b- Closure

FULLY RECESSED

DIMENSIONS†

Up to 1/4 inch adjustment from

minimum 1/4 inch to maximum

1/2 inch recessed position.

Dim. Inches MM

A- 1/2†† 12,7

B-Min. 1 25,4

B-Nom. 1-1/8 28,6

B-Max. 1-1/4 31,8

C-Min. 1/4 6,4

C-Max. 1/2 12,7

HIGH ADJUSTMENT

DIMENSIONS

Up to 1/2 inch adjustment from

the flush ceiling position to

1/2 inch recessed position.

Dim. Inches MM

A- 3/8±1/8†† 9,5±3,2

B-Min. 1 25,4

B-Nom. 1-1/4 31,8

B-Max. 1-1/2 38,1

C-Min. FLUSH —

C-Max. 1/2 12.7

MODEL F700 MODEL F705

A

2a

B

1 2b

(73,0 mm)

2-7/8" DIA.

(57,2 mm)

2-1/4" DIA.

FACE OF

FITTING

MOUNTING

SURFACE

1/8"

(

3,2 mm

)

C

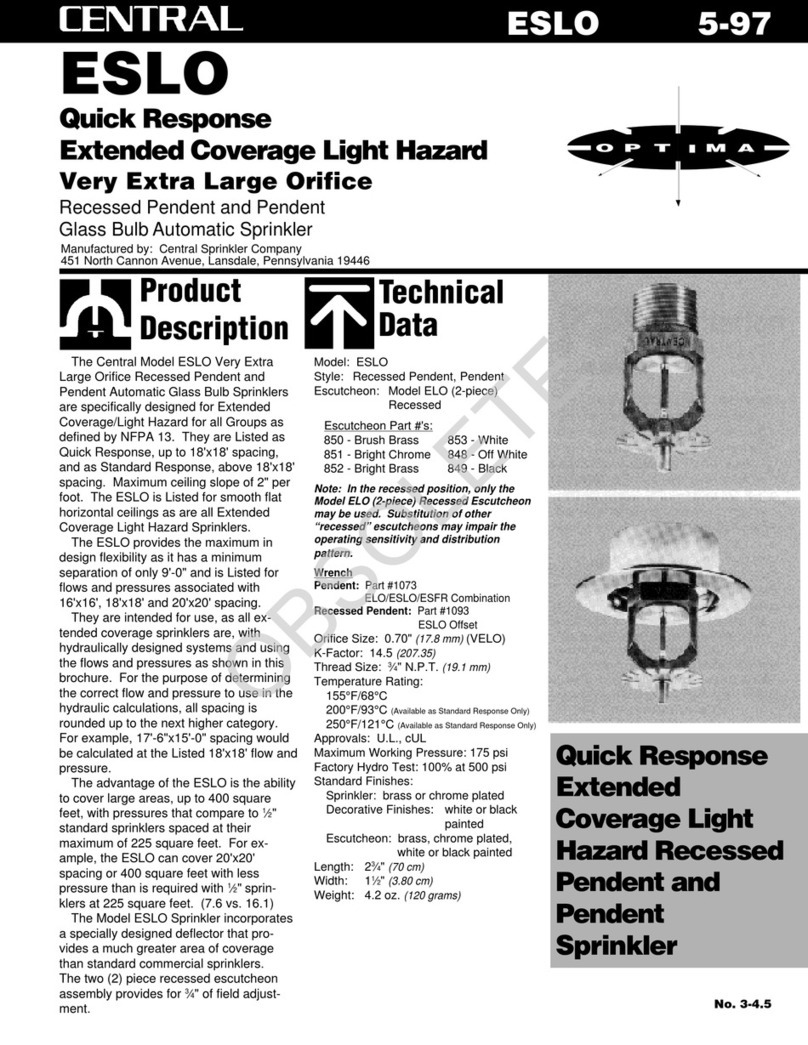

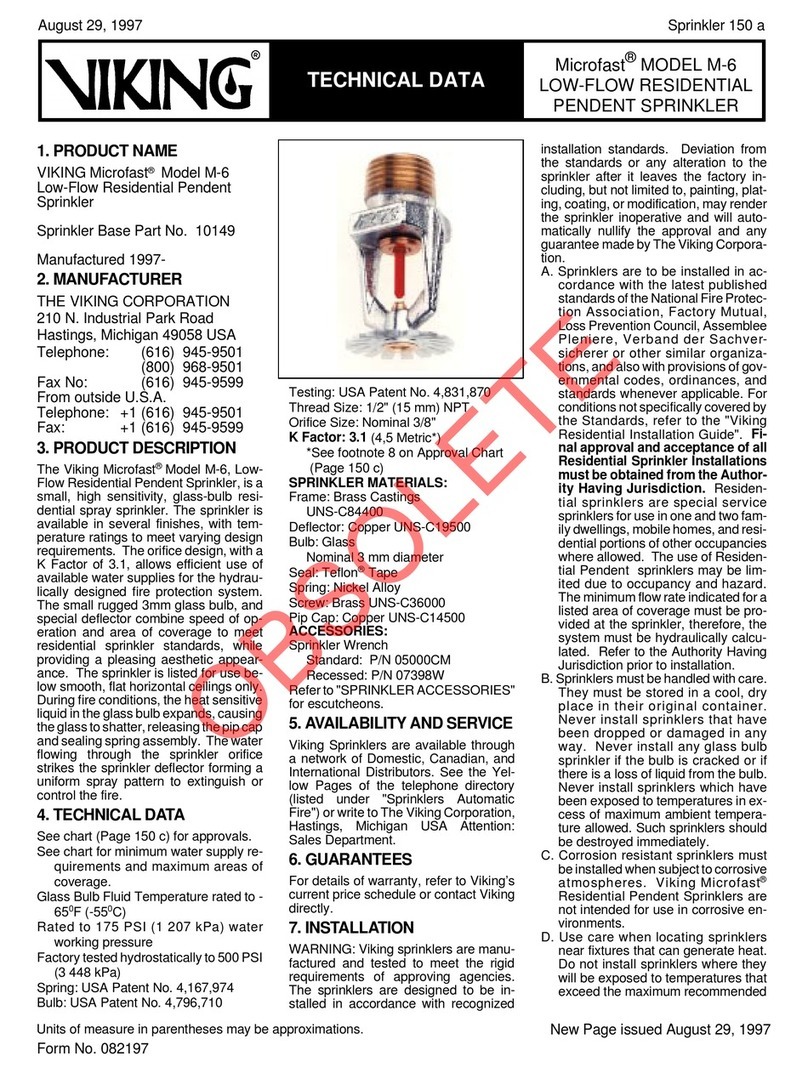

FIGURE D

W-TYPE 6 SPRINKLER WRENCH

WRENCH RECESS

(END "A" USED FOR

1/2" NPT MODELS)

FIGURE E

W-TYPE 7 RECESSED

SPRINKLER WRENCH

RECESS

WREN

C

H

WITH SPRINKLER

ENGAGEMENT

IN TO ENSURE

WREN

C

HIN

G

AREA

PUSH WRENCH

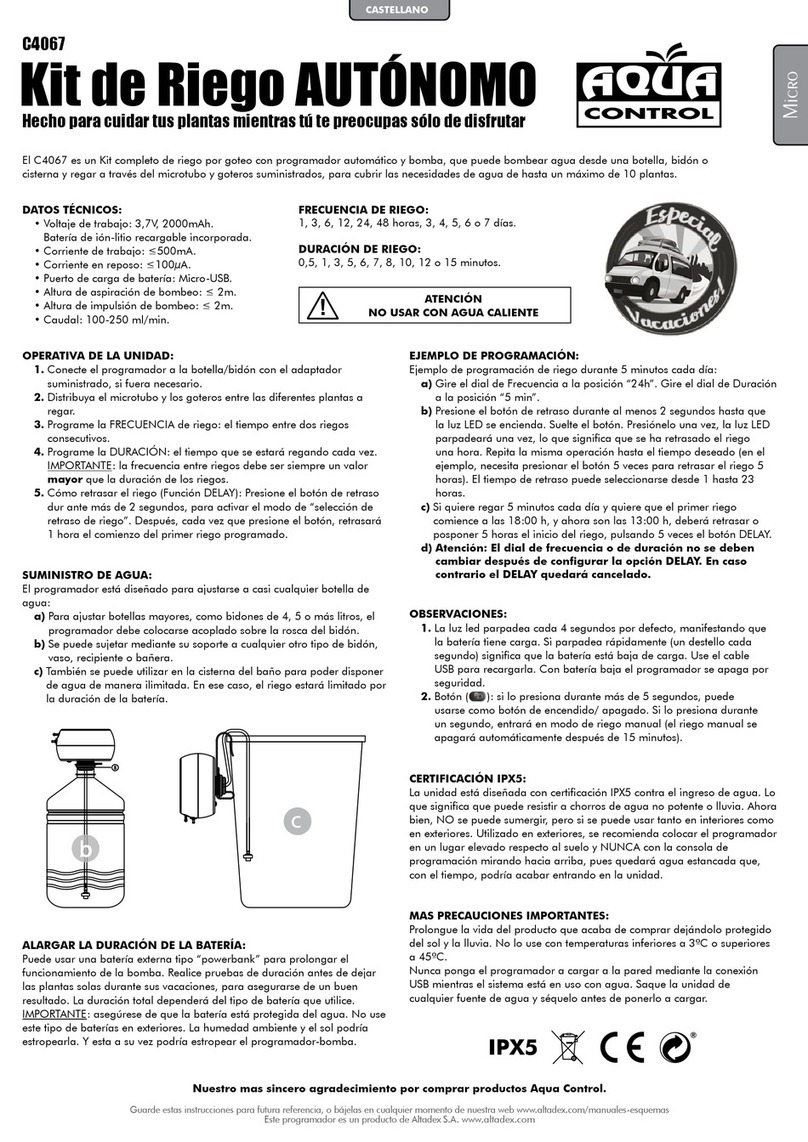

FIGURE C

LEVELING OF SPRINKLER

FITTING AND DEFLECTOR

6 INCH (150 mm) OR

LONGER PIPE NIPPLE

SPRINKLER

DEFLECTOR

CENTERLINE

OF SPRINKLER

WATERWAY

SPIRIT

LEVEL

SPIRIT

LEVEL

SPRINKLER

FITTING

SPRINKLER

OBSOLETE

A leak tight 1/2 inch NPT sprinkler

joint should be obtained with a torque

of 7 to 14 ft.lbs. (9,5 to 19,0 Nm). A

maximum of 21 ft. lbs. (28,5 Nm) of

torque may be used to install sprin-

klers with 1/2 NPT connections.

Higher levels of torque may distort the

sprinkler inlet with consequent leak-

age or impairment of the sprinkler.

When an escutcheon plate is utilized,

do not attempt to make-up for insuffi-

cient escutcheon plate adjustment by

under- or over-tightening the sprin-

kler. Readjust the position of the

sprinkler fitting to suit.

The Model A/Q-71 Horizontal Side-

wall Sprinklers must be installed in

accordance with the following instruc-

tions.

Step 1. Horizontal sidewall sprinklers

are to be installed in the horizontal

position with their centerline of water-

way perpendicular to the back wall and

parallel to the ceiling.

It is recommended that a lightweight

spirit level (less than 1 pound) be used

to level the sprinkler fitting as shown in

Figure C and that a square be used to

to check perpendicularity of the water-

way to the mounting surface.

Step 2. With pipe thread sealant ap-

plied to the pipe threads, hand tighten

the sprinkler into the sprinkler fitting.

Step 3. Tighten the sprinkler into the

sprinkler fitting using only the W-Type

6 Sprinkler Wrench (Ref. Figure C).

With reference to Figure A, the W-

Type 6 Sprinkler Wrench is to be ap-

plied to the wrench flats.

The Model A/Q-71 Recessed Hori-

zontal Sidewall Sprinklers must be

installed in accordance with the follow-

ing instructions.

Step A. Recessed horizontal sidewall

sprinklers are to be installed in the

horizontal position with their centerline

of waterway perpendicular to the back

wall and parallel to the ceiling.

It is recommended that a lightweight

spirit level (less than 1 pound) be used

to level the sprinkler fitting as shown in

Figure C and that a square be used to

to check perpendicularity of the water-

way to the mounting surface.

Step B. Verify that the face of the

sprinkler fitting is within the proper

range of distance which can be accom-

modated by the Model F700 or F705

Recessed Escutcheon.

For best overall appearance, use Di-

mension “A” indicated under the “Fully

Recessed Dimensions” heading of

Figure B. Otherwise, use Dimension

“A” under the “High Adjustment Di-

mensions” heading. In either case, the

remaining adjustment can be used to

compensate for the possible manufac-

turing variations in take-out of the fit-

ting, as well as in the make-in of the

sprinklers (as permitted by ANSI

B1.20.1).

Step C. After installing the F700 or

F705 Mounting Plate over the sprin-

kler threads, hand tighten the sprinkler

into the sprinkler fitting.

Step D. Tighten the sprinkler into the

sprinkler fitting using only the W-Type

7 Recessed Sprinkler Wrench (Ref.

Figure D). With reference to Figure A,

the W-Type 7 Recessed Sprinkler

Wrench is to be applied to the sprinkler

wrench flats.

Step E. After the wall has been in-

stalled or the finish coat has been ap-

plied, slide on the F700 or4 F705 Clo-

sure over the Model A/Q-71 Sprinkler

and push the Closure over the Mount-

ing Plate until its flange comes in con-

tact with the ceiling.

CARE AND MAINTENANCE

The Model A/Q-71 Sprinklers must be

maintained and serviced in accord-

ance with the following instructions:

NOTE

Before closing a fire protection system

control valve for maintenance work

on the fire protection system which it

controls, permission to shut down the

affected fire protection system must be

obtained from the proper authorities

and all personnel who may be affected

by this action must be notified.

Absence of an escutcheon, which is

used to cover a clearance hole, may

delay the time to sprinkler operation

in a fire situation.

Sprinklers which are found to be leak-

ing or exhibiting visible signs of corro-

sion must be replaced.

Automatic sprinklers must never be

shipped or stored where their tempera-

tures will exceed 100°F/38°C and they

must never be painted, plated, coated

or otherwise altered after leaving the

factory. Modified sprinklers must be

replaced. Sprinklers that have been

exposed to corrosive products of com-

bustion, but have not operated, should

be replaced if they cannot be com-

pletely cleaned by wiping the sprinkler

with a cloth or by brushing it with a soft

bristle brush.

Care must be exercised to avoid dam-

age to the sprinklers — before, during,

and after installation. Sprinklers dam-

aged by dropping, striking, wrench

twist/slippage, or the like, must be re-

placed. Also, replace any sprinkler that

has a cracked bulb or that has lost

liquid from its bulb (ref. Installation

Section Note).

Frequent visual inspections are rec-

ommended to be initially performed for

lead coated sprinklers, after the instal-

lation has been completed, to verify

the long term potential integrity of the

sprinkler coatings. Thereafter, annual

inspections per NFPA 25 should suf-

fice; however, instead of inspecting

from the floor level, a random sampling

of close-up visual inspections should

be made, so as to better determine the

exact sprinkler condition and the long

term integrity of the lead coating, as it

may be affected by the corrosive con-

ditions present.

The owner is responsible for the in-

spection, testing, and maintenance of

their fire protection system and de-

vices in compliance with this docu-

ment, as well as with the applicable

standards of the National Fire Protec-

tion Association (e.g., NFPA 25), in

addition to the standards of any other

authorities having jurisdiction. The in-

stalling contractor or sprinkler manu-

facturer should be contacted relative

to any questions.

It is recommended that automatic

sprinkler systems be inspected,

tested, and maintained by a qualified

Inspection Service.

OBSOLETE

LIMITED WARRANTY

Products manufactured by Tyco Fire

Products are warranted solely to the

original Buyer for ten (10) years

against defects in material and work-

manship when paid for and properly

installed and maintained under normal

use and service. This warranty will ex-

pire ten (10) years from date of ship-

ment by Tyco Fire Products. No war-

ranty is given for products or

components manufactured by compa-

nies not affiliated by ownership with

Tyco Fire Products or for products and

components which have been subject

to misuse, improper installation, corro-

sion, or which have not been installed,

maintained, modified or repaired in ac-

cordance with applicable Standards of

the National Fire Protection Associa-

tion, and/or the standards of any other

Authorities Having Jurisdiction. Mate-

rials found by Tyco Fire Products to be

defective shall be either repaired or

replaced, at Tyco Fire Products’ sole

option. Tyco Fire Products neither as-

sumes, nor authorizes any person to

assume for it, any other obligation in

connection with the sale of products or

parts of products. Tyco Fire Products

shall not be responsible for sprinkler

system design errors or inaccurate or

incomplete information supplied by

Buyer or Buyer’s representatives.

IN NO EVENT SHALL TYCO FIRE

PRODUCTS BE LIABLE, IN CON-

TRACT, TORT, STRICT LIABILITY

OR UNDER ANY OTHER LEGAL

THEORY, FOR INCIDENTAL, INDI-

RECT, SPECIAL OR CONSEQUEN-

TIAL DAMAGES, INCLUDING BUT

NOT LIMITED TO LABOR CHARGES,

REGARDLESS OF WHETHER TYCO

FIRE PRODUCTS WAS INFORMED

ABOUT THE POSSIBILITY OF SUCH

DAMAGES, AND IN NO EVENT

SHALL TYCO FIRE PRODUCTS’ LI-

ABILITY EXCEED AN AMOUNT

EQUAL TO THE SALES PRICE.

THE FOREGOING WARRANTY IS

MADE IN LIEU OF ANY AND ALL

OTHER WARRANTIES EXPRESS

OR IMPLIED, INCLUDING WARRAN-

TIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PUR-

POSE.

ORDERING PROCEDURE

A Product Symbol Number (PSN) is

not specified when ordering sprinklers

with thread connections per ISO 7/1.

Contact your local distributor for avail-

ability.

Sprinkler Assemblies:

Specify: 5.6 K-Factor, (specify tem-

perature rating), Quick Response

Model A/Q-71 Horizontal Sidewall

Sprinkler with (specify type of finish or

coating), PSN (specify from Table B).

“Special Order”

Sprinkler Assemblies with ISO 7/1

Thread Connections:

Specify: 5.6 K-Factor, (specify tem-

perature rating), Quick Response

Model A/Q-71 Horizontal Sidewall

Sprinkler with (specify type of finish or

coating) and with thread connection

per ISO 7/1.

Recessed Escutcheon:

Specify: 1/2" (15 mm) Model F700 Re-

cessed Escutcheon with (specify fin-

ish), PSN (specify).

1/2" F700 Chrome . . . . . . . . PSN 56-701-9-010

1/2" F700 White . . . . . . . . . . PSN 56-701-4-010

1/2" F705 Chrome . . . . . . . . PSN 56-705-9-010

1/2" F705 White . . . . . . . . . . PSN 56-705-4-010

Sprinkler Wrench:

Specify: W-Type 6 Sprinkler Wrench,

PSN 56-000-6-387.

Specify: W-Type 7 Sprinkler Wrench,

PSN 56-850-4-001.

PATENTS

The following patents are applicable to

the Model A/Q-71 Horrizontal Sidewall

Sprinklers:

COUNTRY............ PATENTNO.

U.S.A. ................ 5,810,263

UnitedKingdom........... 2,347,624

WEIGHT

The nominal weights are as follows.

5.6 K-Factor Model A/Q-71

Horizontal Sidewall Sprinkler . . 2.3 ozs. (66 g)

1/2" Model F700

Recessed Escutcheon . . . . . . . 1.3 ozs. (38 g)

1/2" Model F705

Recessed Escutcheon . . . . . . . 1.2 ozs. (35 g)

W-Type 6

Sprinkler Wrench . . . . . . . . . . . 12.0 ozs. (340 g)

W-Type 7

Sprinkler Wrench . . . . . . . . . . . 15.5 ozs. (440 g)

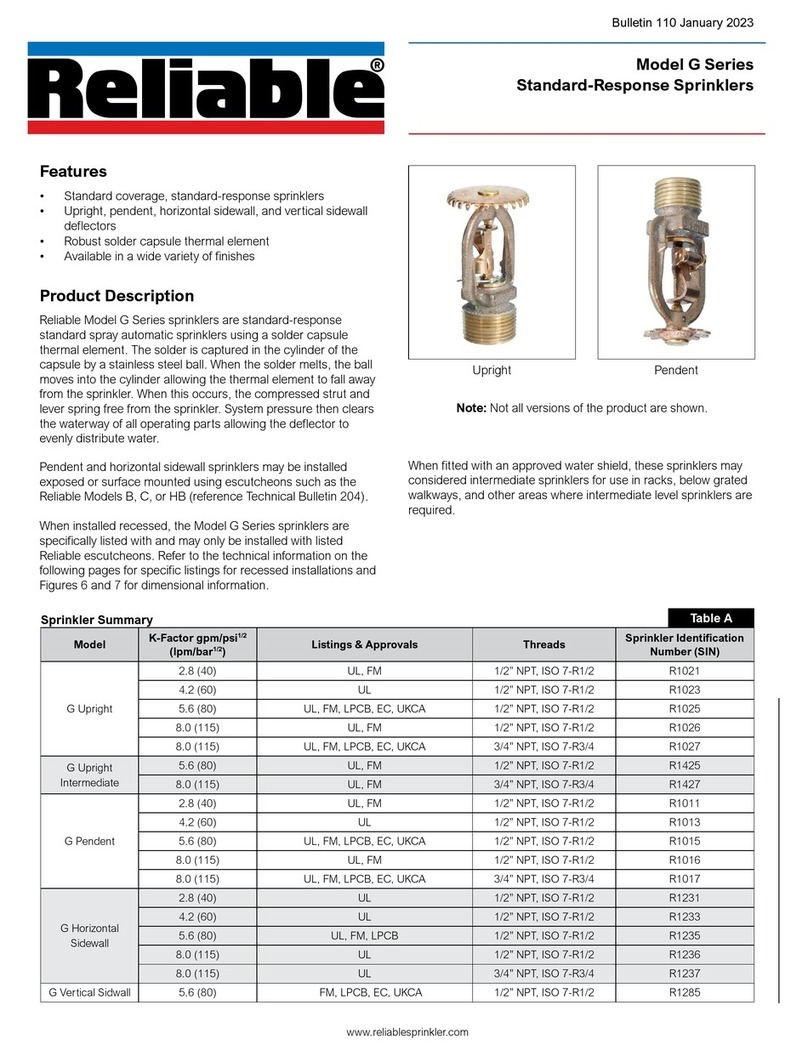

PSN 57 — XXX — X — XXX

155°F/68°C155

TEMPERATURE

RATING

135°F/57°C135

QR

HORIZONTAL

SIDEWALL

378

1

SPRINKLER

FINISH

TABLE B

PRODUCT SYMBOL NUMBER SELECTION

5.6 K-FACTOR MODEL A/Q-71 HORIZONTAL SIDEWALL SPRINKLERS

WITH 1/2 INCH NPT CONNECTIONS

175°F/79°C

286

200°F/93°C200

286°F/141°C

175WHITE POLYESTER

NATURAL BRASS

9

4

TYPE CHROME PLATED

7 LEAD COATED

OBSOLETE

OBSOLETE

Table of contents

Other GEM Irrigation System manuals