TFP461

Page 2 of 6

Operation

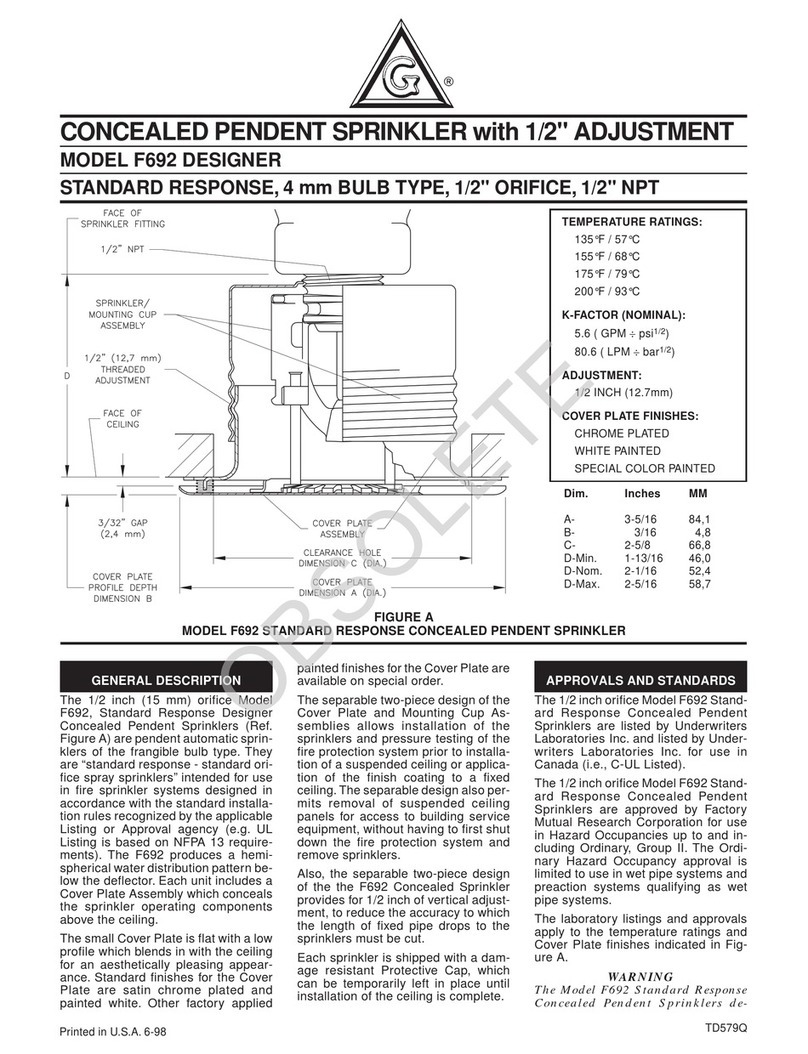

When the TYCO Series LFII Dry Type

Residential Horizontal Sidewall Sprin-

kler is in service, water is prevented

from entering the assembly by the Plug

with Sealing Assembly (see Figure 1) in

the Inlet of the Sprinkler.

The glass Bulb contains a fluid that

expands when exposed to heat. When

the rated temperature is reached, the

fluid expands sufficiently to shatter the

glass Bulb to release the Bulb Seat. The

system’s water pressure is then able to

unseat the Plug with Sealing Assem-

bly. The Plug Spring turns the Plug with

Sealing Assembly aside, allowing the

sprinkler to activate and flow water.

Design

Criteria

The TYCO Series LFII Dry Type Resi-

dential Horizontal Sidewall Sprinklers

(TY2335) are UL and C-UL Listed for

installation in accordance with this

section.

Residential Sprinkler Design Guide

When conditions exist that are outside

the scope of the criteria provided in

this section, refer to the technical data

sheet entitled Residential Sprinkler

Design Guide (TFP490) for the manu-

facturer’s recommendations that may

be acceptable to the local authority

having jurisdiction.

System Type

Wet Pipe

Hydraulic Design

(NFPA 13D and 13R)

For systems designed to NFPA 13D or

NFPA 13R, the minimum required sprin-

kler flow rates are given in Table A as a

function of temperature rating and the

maximum allowable coverage areas.

The sprinkler flow rate is the minimum

required discharge from each of the

total number of design sprinklers, as

specified in NFPA 13D or NFPA 13R.

Hydraulic Design

(NFPA 13)

For systems designed to NFPA 13, the

number of required design sprinklers is

the four most hydraulically demanding

sprinklers. The minimum required dis-

charge from each of the four sprinklers

is the greater of the following:

•

ow rates listed in Table A as a

function of temperature rating and

the maximum allowable coverage

area.

•

minimum discharge of 0.1 gpm/ft²

over the design area comprised

of the four most hydraulically

demanding sprinklers for the actual

coverage areas protected by four

sprinklers.

Obstruction to Water Distribution

Sprinklers are to be located in accor-

dance with the obstruction rules of

NFPA 13D, 13R, and 13 as applicable

for residential sprinklers as well as with

the obstruction criteria described within

the Technical Data Sheet TFP490.

Operational Sensitivity

The sprinkler must be located relative

to the mounting surface as shown in

Figures 2 and 3.

Sprinkler Spacing

The minimum lateral spacing between

sprinklers is 8 ft (2,4 m). The maximum

lateral spacing between sprinklers

cannot exceed the length of the cov-

erage area (see Table A) hydraulically

calculated (for example, a maximum of

12 ft for a 12 ft x 12 ft coverage area or

18 ft for a 18 ft x 20 ft coverage area.)

Sprinkler Fittings

The following fittings may be used:

•

the 1 in. NPT outlet or run of a

malleable or ductile iron threaded

tee ttings that meet the dimen-

sional requirements of ANSI B16.3

(Class 150)

•

the 1 in. NPT outlet or run of a cast

iron threaded tee tting that meet

the dimensional requirements of

ANSI B16.4 (Class 125)

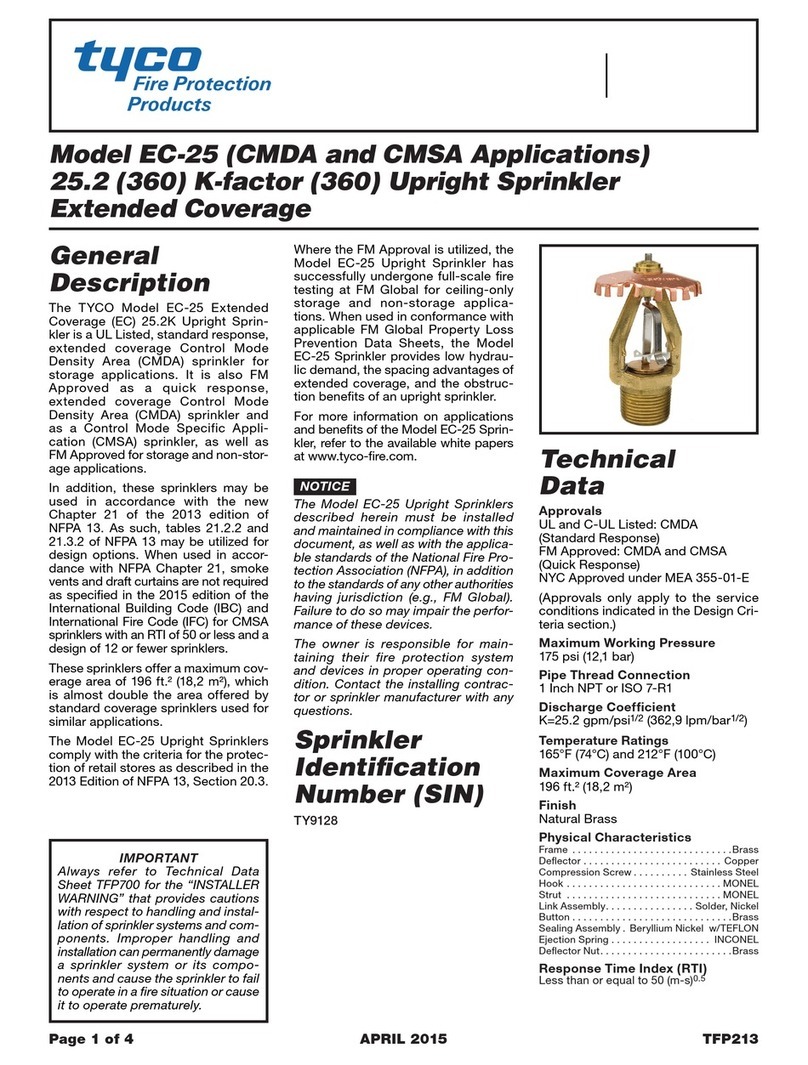

Technical

Data

Approvals

UL and C-UL Listed

Certified to all requirements of

NSF/ANSI 61

Note: Sprinklers with a polyester finish are

UL and C-UL Listed as corrosion-resistant

sprinklers.

See the Design Criteria section for details

on these approvals.

Maximum Working Pressure

175 psi (12,1 bar)

Discharge Coefficient

K=4.4 GPM/psi½(63,4 LPM/bar½)

Inlet Thread Connections

1 in. NPT

ISO 7-R 1

Sprinkler Temperature Rating

155°F (68°C)

Finishes

Natural Brass, Signal White Polyester

Coated, or Chrome Plated

Order Lengths

Minimum: 3-3/4 in. (95,3 mm)

Maximum: 24 in. (609,6 mm)

Physical Characteristics

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Brass

Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Brass

Yoke....................... Stainless Steel

Casing ....................Galvanized Steel

Insert . . . . . . . . . . . . . . . . . . . . . . . . . . . Bronze

Bulb Seat. . . . . . . . . . . . . . . . . . . Stainless Steel

Bulb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Glass

Compression Screw . . . . . . . . . . . . . . . . . .Brass

Deflector . . . . . . . . . . . . . . . . . . . . . . . . . . Brass

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Brass

Guide Tube . . . . . . . . . . . . . . . . . Stainless Steel

Water Tube . . . . . . . . . . . . . . . . . Stainless Steel

Bushing . . . . . . . . . . . . . . . . . . . . . . . . . . . .Brass

Plug Spring . . . . . . . . . . . . . . . . . Stainless Steel

Sealing Assembly ..Beryllium Nickel w/TEFLON

Escutcheon . . . . . . . . . . . . . . . . . . .Carbon Steel

TUBE

VENT

HOLE

TUBE

BULB

SEAT

SCREW

BULB

INLET

BAND

SPRING

ESCUTCHEON

MOUNTING PLATE

INLET

YOKE

CASINGBUSHING

FRAMEPLUG WITH

SEALING

ASSEMBLY

FIGURE 1

SERIES LFII DRY TYPE

RESIDENTIAL HORIZONTAL SIDEWALL SPRINKLERS (TY2335) ASSEMBLY