3

The Model GB and GB-QR Dry Sidewall Sprinklers are intended for standard

area coverages and standard flow and pressure requirements as specified in

current NFPA 13 Standards.

Design

Data

Design Requirements—Standard Applications

All Model GB and GB-QR Dry

Sidewall Automatic Sprinklers must

be installed according to current

NFPA 13 Standards. Deviations from

these requirements and standards or

any alteration to the sprinkler itself

will void any warranty made by

Central Sprinkler Company. In

addition, installation must also meet

local government provisions, codes

and standards as applicable.

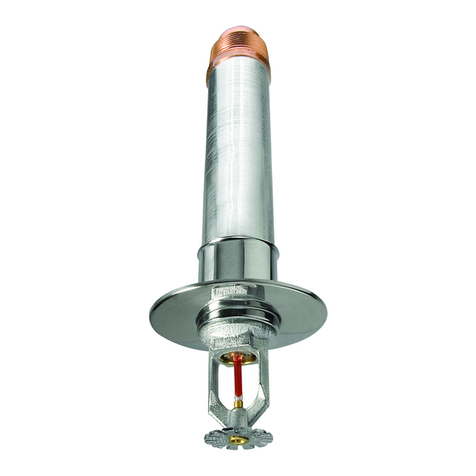

Dry sprinklers are designed to

prevent water from accumulating in

drops to sprinklers. To accomplish

this, they have a fitting that protrudes

into the branch line that allows the

plug to sit above the water line, if

there is any residual water, and

operate without the potential of

freezing. Always install dry sprinklers

in a threaded tee.

For standard applications the

system piping may be hydraulically

calculated or pipe-scheduled. Check

for the proper model, style, orifice

size, and temperature rating prior to

installation. Install sprinklers after the

piping is in place to avoid mechanical

damage; replace any damaged units.

Wet pipe systems must be protected

from freezing.

Upon completion of the installation,

the system must be tested per

recognized standards.

In the event of a thread leak,

remove the unit, apply new pipe joint

compound or tape, and reinstall.

Installation Sequence

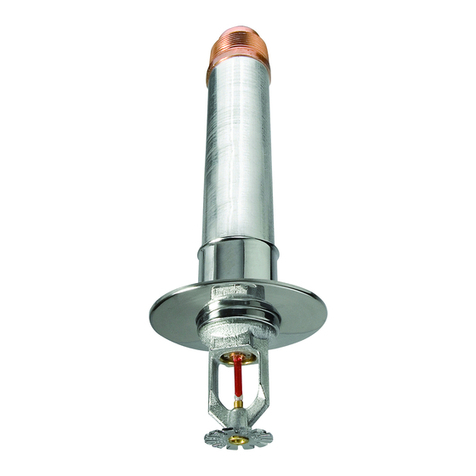

Step 1. The unit must be installed

into a threaded, cast iron, ductile

Installation iron, or malleable iron tee only. It

may be installed into the run or

outlet of this tee. Do not install

into an elbow or mechanical tee.

Step 2. Use only a non-hardening

pipe joint compound or Teflon* tape.

Apply only to the male threads.

*Teflon is a trademark of the DuPont Corp.

Step 3. Hand tighten the dry sidewall

assembly into the fitting. Use the

appropriate Central Sprinkler dry

pendent wrench to tighten the unit in

the fitting. A leak tight joint requires

only 7 to 14 ft. lbs. (9.5 to 19.0 Nm) of

torque; a tangential force of 14 to 28

lbs. (62.3 to 124.5 N) delivered

through a 6" (150 mm) handle will

deliver adequate torque. The Model

GB dry sidewall can be installed by

using the correct wrench on either the

sprinkler wrench boss or the barrel of

the dry sidewall.

Step 4. To install the escutcheon

plate, align it with and push it over the

sprinkler body and into the upper

support piece until the outer edge of

the escutcheon meets the mounting

surface. The recessed escutcheon

tool may be used to install the

escutcheon plate easily from the floor.

Do not over- or under-tighten the

sprinkler to compensate for inaccu-

rate escutcheon plate adjustment.

Caution: If installing in a CPVC

system, appropriate adaptation must

be made to insure that the dry

pendent is being installed into a

threaded, cast iron, ductile iron, or

malleable iron tee only. Special care

must be taken when installing with a

CPVC system. Sprinklers must be

installed after the manufacturer's

recommended setting time for the

Sprinklers must be handled care-

fully. They must not be transported

or stored where ambient temperature

may exceed 100°F/38°C. For best

results, store them in a dry, cool

location in the original shipping

package.

Do not install sprinklers that have

been dropped or visibly damaged,

such as a crack in a glass bulb or a

loss of liquid from the bulb. Sprinklers

should never be painted, coated,

plated or altered in any other way

from manufactured condition or they

may not function properly. Any

sprinklers altered in such a manner

must be replaced.

The owner is responsible for the

proper operating condition of all fire

protection devices and accessories.

The NFPA standard 25 entitled,

“Inspection, Testing and Maintenance

of Water-Based Fire Protection

Systems”

, contains guidelines and

minimum maintenance requirements.

Furthermore, the local

Authority

Having Jurisdiction

may have addi-

tional regulations and requirements

for maintenance, testing, and inspec-

tion that must be obeyed.

It is advisable to have sprinkler

systems inspected regularly by a

qualified inspection service. Length

of time between such inspections can

vary due to accessibility, ambient

atmosphere, water supply, and site

activity.

Care &

Maintenance

primer and cement to ensure that

neither accumulate within the sprinkler.

Special care must be taken when

installing with a copper system.

Sprinklers must be installed only after

the inside of the sprinkler drop and

associated fittings have been wire

brushed to remove any flux. Residual

flux can cause corrosion and in

extreme cases can impair proper

sprinkler operation.