Design Criteria

ULandC-ULListing

Requirements

The 16.8 K-factor, Model K17-231

(TY7151 & TY7251) Sprinklers may be

installed in accordance with NFPA 13

standard sprinkler position and

area/density flow calculation require-

ments for light, ordinary, or extra haz-

ard occupancies with a minimum re-

sidual (flowing) pressure of 7 psi (0,5

bar) in wet or dry pipe sprinkler sys-

tems, or they may be installed in ac-

cordance with NFPA 13 standard

sprinkler position and area/density

flow calculation requirements for high

piled storage occupancies (solid piled,

palletized, rack storage, bin box, and

shelf storage including but not limited

to Class I-IV and Group A plastics) with

a minimum residual (flowing) pressure

of 7 psi (0,5 bar) for wet or dry pipe

systems.

The following two examples are typical

of the types of arrangements permitted

by NFPA 13. For all combinations of

lesser and greater building heights,

lesser and greater storage heights,

storage arrangements, commodity

classifications, and lesser or greater

required design densities, refer to

NFPA 13 for specifics.

Example 1: NFPA 13 provides ceiling

only protection (i.e., no in-rack sprin-

klers) criteria using open frame (i.e. no

solid shelves) single, double, multiple-

row, or portable rack storage (without

the need for in-rack sprinkler protec-

tion) of cartoned or uncartoned unex-

panded Group A or B plastics, or, car-

toned expanded Group A or B plastics,

with:

•

a storage height of up to 20 feet (6,1

m);

•

a maximum ceiling height of 27 feet

(8,2 m);

•

a minimum deflector to top of stor-

age clearance of 18 inches (457

mm);

•

a minimum design density of 0.60

gpm/ft2(24,4 mm/min);

•

a minimum residual (flowing) pres-

sure of 7 psi (0,5 bar);

•

a minimum design area of 2000 ft2

(186 m2) for wet systems or 2600 ft2

(242 m2) for dry pipe systems

Example 2: NFPA 13 provides ceiling

only protection (i.e., no in-rack sprin-

klers) criteria using open frame (i.e. no

solid shelves) single, double, multiple-

row, or portable rack storage (without

the need for in-rack sprinkler protec-

tion) of cartoned or uncartoned unex-

panded Group A or B plastics, or, car-

toned expanded Group A or B plastics,

with:

•

a storage height of up to 25 feet (7,6

m);

•

a maximum ceiling height of 30 feet

(9,1 m);

•

a minimum deflector to top of stor-

age clearance of 18 inches (457

mm);

•

a minimum design density of 0.80

gpm/ft2(32,6 mm/min);

•

a minimum residual (flowing) pres-

sure of 7 psi (0,5 bar);

•

a minimum design area” of 2000 ft2

(186 m2) for wet systems or 4500 ft2

(418 m2) for dry pipe systems

FM Approval

Requirements

The 16.8 K-factor, Model K17-231

(TY7151) Upright Sprinklers may be

installed in accordance with the appli-

cable “control mode density/area”

guidelines provided by Factory Mutual.

(FM guidelines may differ from UL and

C-UL Listing criteria.)

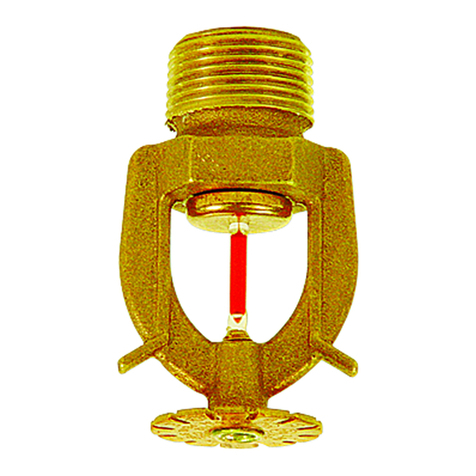

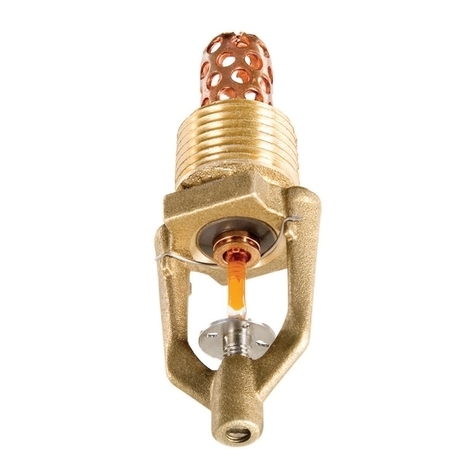

Operation

The glass bulb contains a fluid that

expands when exposed to heat. When

the rated temperature is reached, the

fluid expands sufficiently to shatter the

glass bulb, allowing the sprinkler to

activate and flow water.

Page2of4 TFP332

TYPE TEMP. BULB

LIQUID

NATURAL

BRASS

286°F/141°C

PENDENT

K=16.8 (TY7251)

SPRINKLER FINISH

1, 2, 4

Red

Green

Blue

155°F/68°C

200°F/93°C

NOTES:

1. Listed by Underwriters Laboratories, Inc. (UL Listed).

2. Listed by by Underwriters Laboratories, Inc. for use in Canada (C-UL Listed).

3. Approved by Factory Mutual Research Corporation (FM Approved).

4. Approved by the City of New York under MEA 177-03-E.

TABLE A

LABORATORY LISTINGS AND APPROVALS

(Refer to the Design Criteria Section)

155°F/68°C Red

200°F/93°C Green

286°F/141°C Blue

1, 2, 3, 4UPRIGHT

K=16.8 (TY7151)