Hot-Shot™

2. Dress properly. Do not wear loose clothing

or jewelry. Contain long hair. Keep your

hair, clothing, and gloves away from moving

parts. Loose clothes, jewelry, or long hair can

be caught in moving parts.

3. Avoid accidental starting. Be sure switch is

off before plugging in. Plugging in tools that

have the switch on invites accidents.

4. Do not overreach. Keep proper footing and

balance at all times. Proper footing and

balance enables better control of the tool in

unexpected situations.

5. Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for

appropriate conditions.

Tool Use and Care

1. Use clamp or other practical way to secure

and support the workpiece to a stable

platform. Holding the work by hand or against

your body is unstable and may lead to loss of

control.

2. Do not use tool if switch does not turn it on

or off. Any tool that cannot be controlled with

the switch is dangerous and must be repaired.

3. Disconnect the plug from the power source

before making any adjustments, changing

accessories, or storing the tool. Such

preventative safety measures reduce the risk of

starting the tool accidentally.

4. Store idle tools out of reach of children and

other untrained persons. Tools are

dangerous in the hands of untrained users.

5. Use only accessories that are recommended

by the manufacturer for your model.

Accessories that may be suitable for one tool

may become hazardous when used on another

tool.

Tool Service

1. Tool service must be performed only by

qualified repair personnel. Service or

maintenance performed by unqualified repair

personnel could result in injury.

2. When servicing a tool, use only identical

replacement parts. Follow instructions in

the Maintenance section of this manual.

Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of

electric shock or injury.

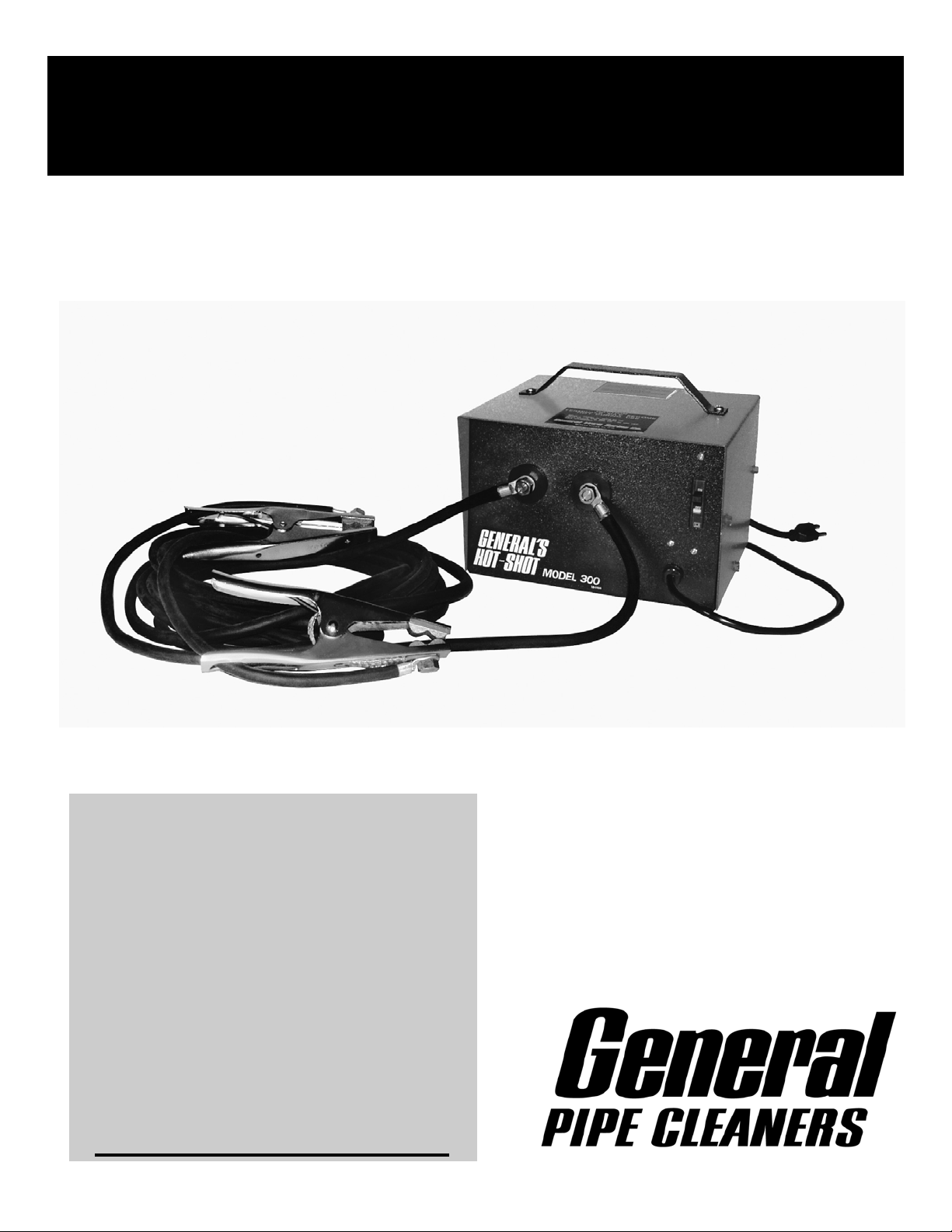

Introduction

A frozen water pipe can be thawed very quickly by

passing low voltage high current electricity through

the frozen pipe. Plastic pipe will not conduct

electricity so this method will not work on

plastic pipe. There must be unfrozen water under

standard water pressure on one side of the frozen

part of the pipe and an open faucet on the other

side.

When thawing a frozen section of water pipe, heat

the pipe only enough to melt a thin film of ice in the

inside of the pipe. A faucet must be opened in

the unfrozen part of the line down stream from the

frozen section. The warmer water above the ice

will seep through the melted film and very quickly

melt the rest of the ice. The water will start to flow

in about 10 minutes if the connections are properly

made. Since copper pipe will not heat as fast as

steel pipe, allow about a 30 percent longer thawing

time. (See Chart)

Features

• The Hot-Shot CHS-300 puts out 325 amps, yet

pulls only 17 amps. It can clear 1/2" to 1-1/2"

pipes up to 100 ft. long.

• The unit has a built-in thermal protector. If the

internal temperature reaches a critical level, the

Hot-Shot will automatically shut down.

Warnings

• The Hot-Shot CHS-300 requires a 115 volt AC

grounded 20 amp circuit.

• Be sure the unit is plugged into a properly

grounded receptacle. If in doubt, check

receptacle before plugging in unit.

• If the power cord supplied with the unit is not

long enough, be sure to use a grounded heavy

duty extension cord that is in good condition.

Using lighter cords can result in severe power

loss and overheating.

• There is a possibility that the output current of

the unit may be transferred into the electrical

service, either at the house being thawed, or at

a remote location. Therefore, all grounds (i.e.

electric service, telephone, and cable TV

grounds) must be disconnected, both at the

house being thawed and all houses on the

same distribution transformer.

• Do not leave unit unattended while thawing. Do

not leave unit operating overnight.

Operating Instructions

1. Isolate the frozen section of pipe. Inside a

house, this is done by opening faucets and

back tracking the pipes. The frozen section will

3