ZH284KEZ

GENERAL PUMP A member of the Interpump Group

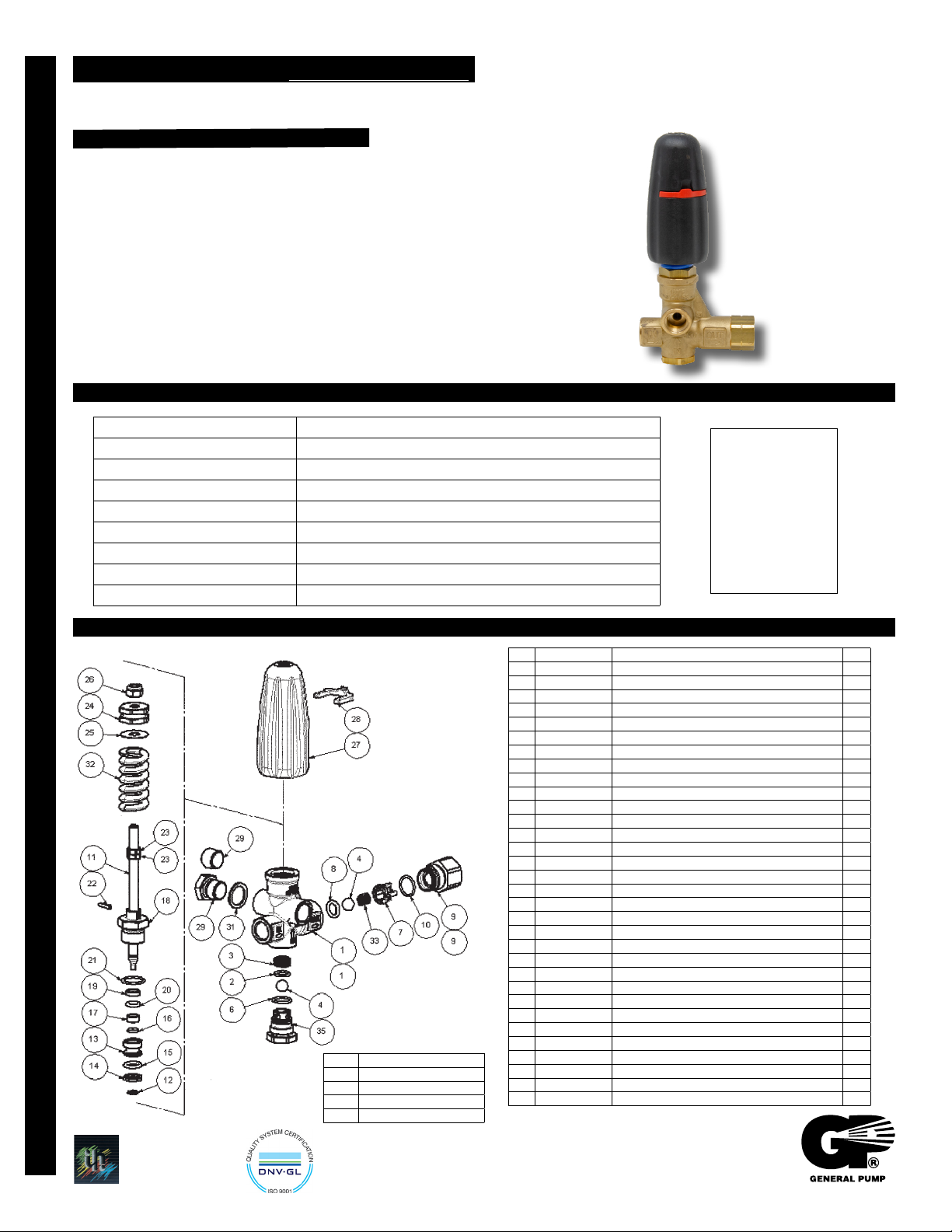

Trapped Pressure Unloader Valve

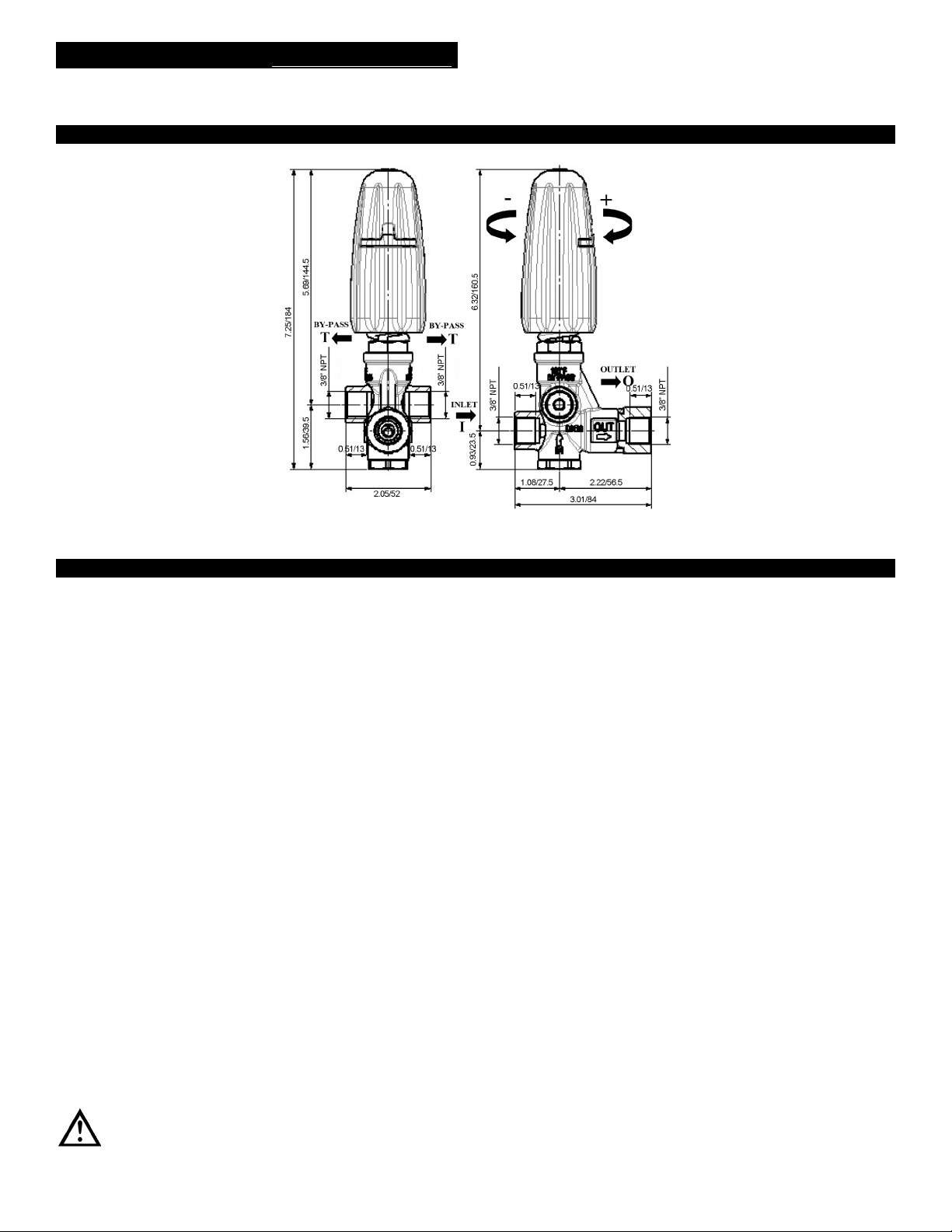

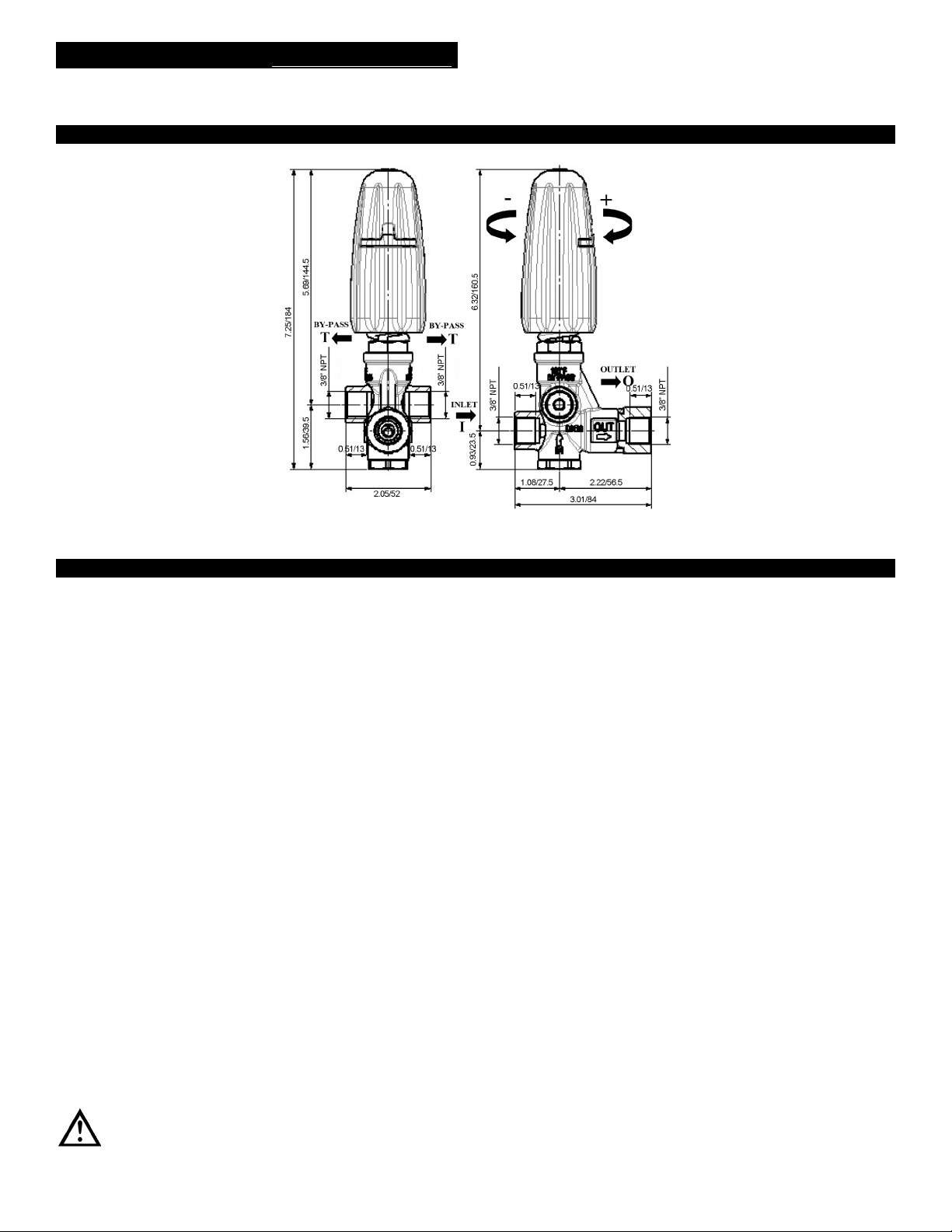

DIMENSIONS

THIS DOCUMENT PROVIDES THE INSTRUCTIONS FOR THE INSTALLATION, USE AND MAINTENANCE OF THE VALVE, THEREFORE IT IS

AN INTEGRAL PART OF THE VALVE ITSELF AND MUST BE READ CAREFULLY BEFORE ANY USE AND KEPT WITH CARE.

STRICTLY COMPLY WITH THE INSTRUCTIONS CONTAINED IN THIS DOCUMENT IN VIEW OF A SAFE AND EFFECTIVE USE OF THE VALVE.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS MIGHT CAUSE EARLY FAULTS AND RESULT IN SITUATIONS OF DANGER, IN

ADDITION TO VOIDING ANY WARRANTY.

1-GENERAL INFORMATION:

1.1- The ZH284KEZ automatic pressure regulator is a manually-adjustable, pressure-operated device which, according to its setting, limits the pump/

system pressure by conveying the excess of water to the by-pass. Moreover, when the outlet flow is blocked, this device totally releases the flow - and

keeps under pressure the portion of the system following the valve, while it sets the pressure to zero in the portion of the system preceding the valve.

2-WARNINGS:

2.1- To ensure the tightness of the fittings used to connect the valve to the system, interpose a metal washer with a rubber ring or insert an appropri-

ate sealing on the thread and tighten them.

2.2- Use guns or other control devices ensuring a perfect seal when closed. Leakages may compromise the correct functioning of the valve.

2.3 - WARNING: The nut pos. 23 is a mechanical security stop that limits the maximum pressure. Do not remove for any reason.

3-INSTRUCTIONS FOR CALIBRATION:

The valve is calibrated to the maximum pressure value shown in the table, IT IS NOT ALLOWED TO EXCEED THIS VALUE

3.1- Connect the valve to the water system and follow these steps:

3.2- Unloose the adjustment knob pos.27 in order to completely release the spring.

3.3- Open the gun or the water control device and start the system. Make sure that the air contained in it is fully ejected.

3.4- Keeping the gun or the water control device open, start adjusting the pressure by screwing down the knob pos.27. Alternate the adjusting oper-

ations with a few openings and closings of the gun or of the control device. When the desired pressure has been reached, open and close the gun/

control device a few times again in order to stabilize the various components (seals, springs etc.). Check the pressure value again and correct if nec-

essary.

In case of doubts, do not hesitate to contact the General Pump Customer Service.

IMPORTANT: During use, never exceed the maximum values of pressure, flow-rate and temperature as stated in this document and/

or indicated on the valve.

INSTALLATION AND INSTRUCTIONS FOR USE

Ref 301085 Rev. B

02-22