P/ GE SLICERMA

RevA 10-2011

1

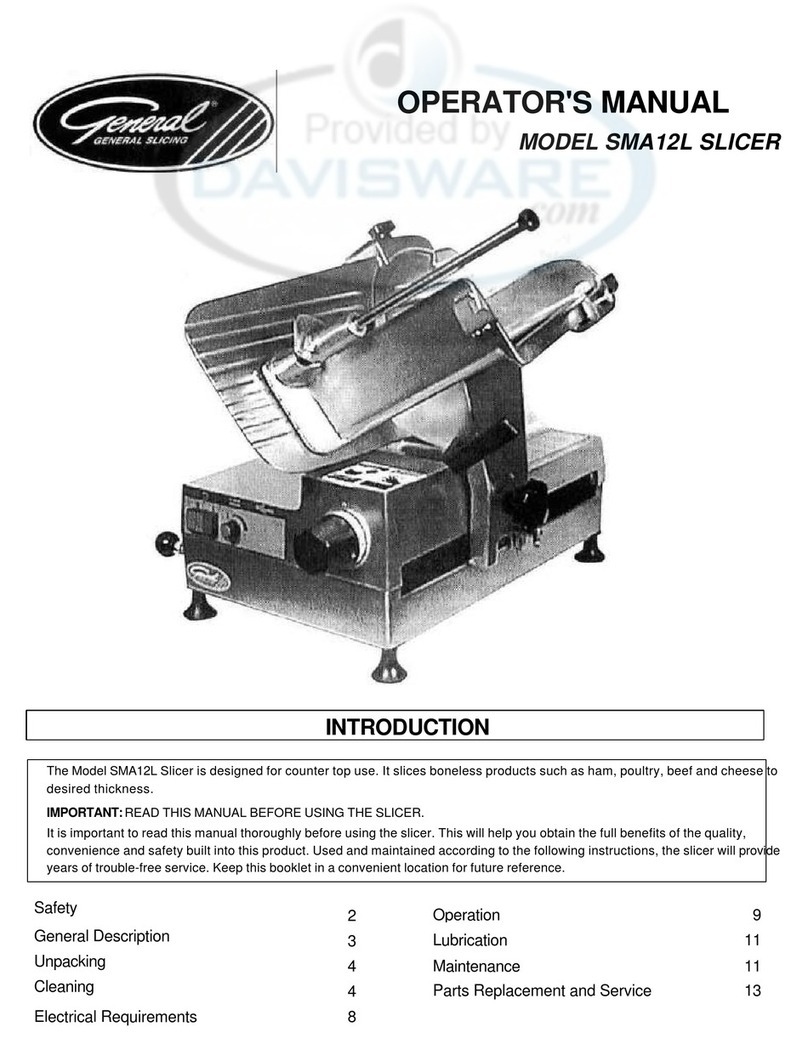

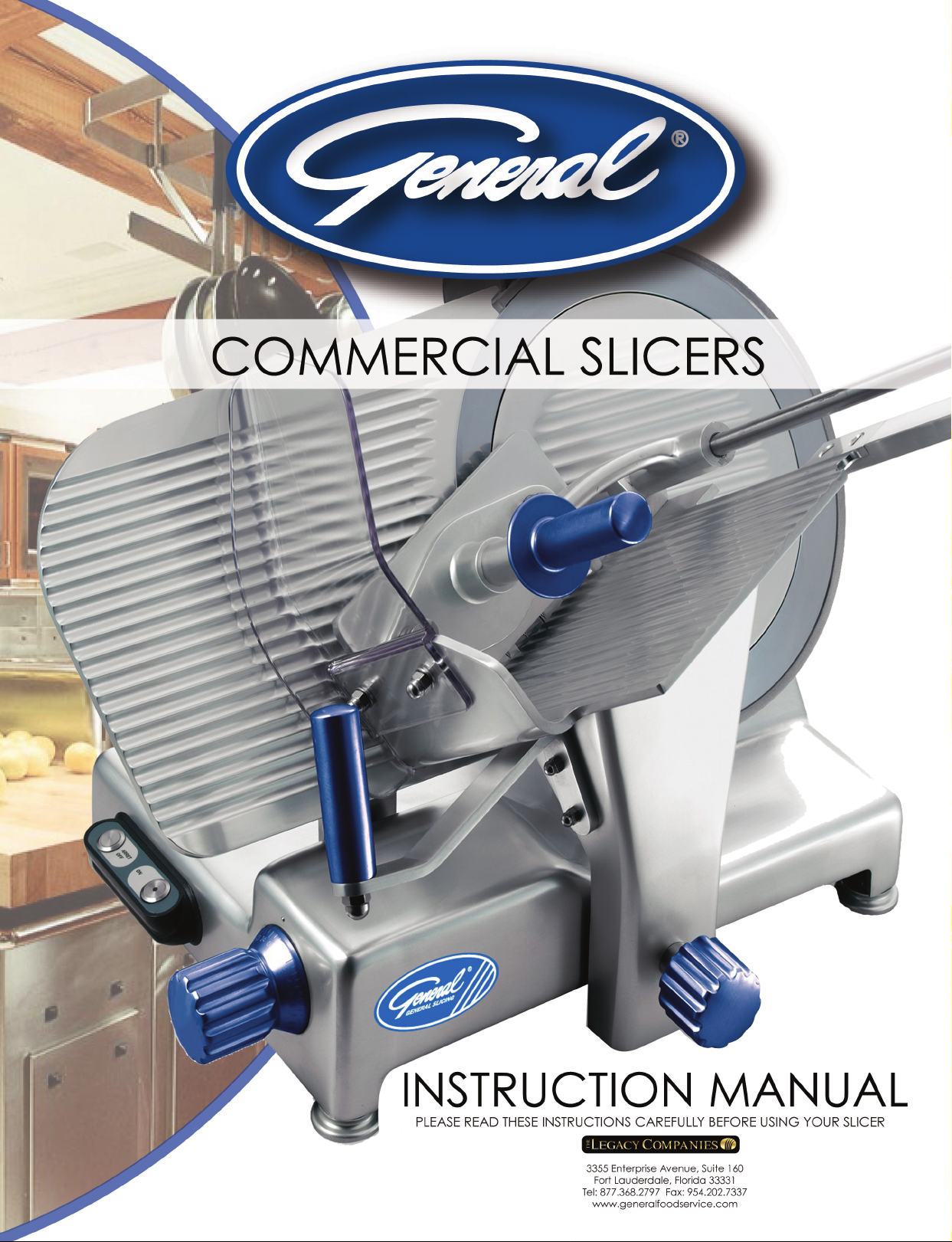

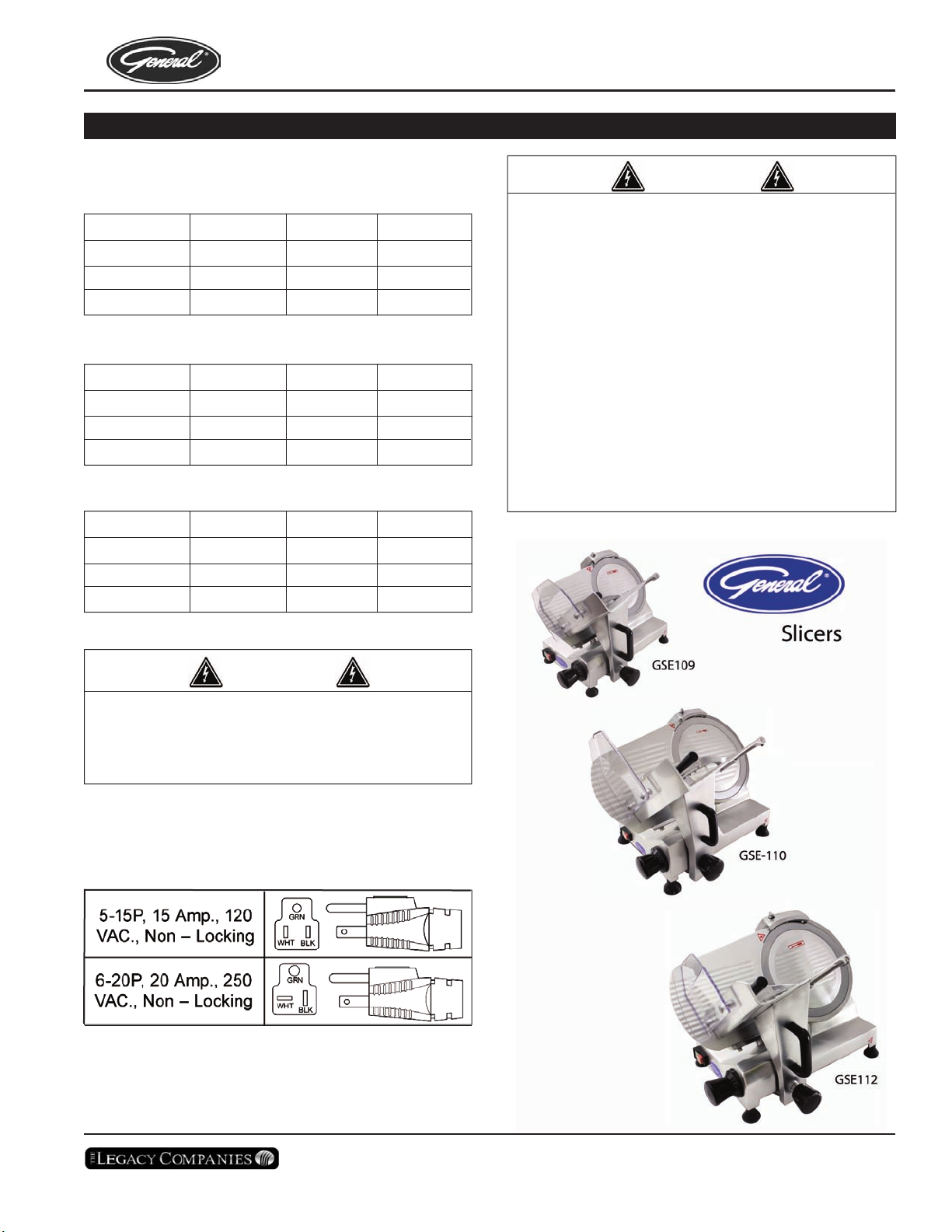

GSE-109-110-112 SLICER

Thank you for purchasing this quality General product

brought to you by The egacy Companies. Your new

General GSE-109, GSE-110 and/or GSE-112 was

designed with advanced performance and safety fea-

tures that make it a valued addition to your kitchen

equipment package. Like all General products and

accessories the GSE-109, GSE-110 and GSE-112 are

manufactured to give years of reliable service.

The General GSE-109 (nine inch), GSE-110 (ten inch)

and GSE-112 (twelve inch) slicers are heavy duty pre-

cision crafted, versatile units. These all-purpose slicers

use an all stainless steel drive system that provides for

years of corrosion free operation. The heat treated

carbon steel knife was designed for years of use.

Each slicer comes standard with a stainless steel drive

system, On board knife sharpener, safety interlock

switch, easy to use controls, smooth rounded corners

and edges and a anti-microbrial finish. The power con-

trol switch has a moisture resistant protective covering

and all units come equipped with a motor overload

switch to protect the motor from amperage overload.

The GE ERAL brand GSE-109, GSE-110 and GSE-

112 SLICERS remove the guesswork and produce a

uniform finished product from one operator to the next.

Thank You Again for Your Purchase!

OWNER INFORMATION

GE ERAL warrants to the original purchaser of the

GSE-109, GSE-110 and GSE-112 slicers, all parts

thereof to be free from defects in material and work-

manship while under normal use. Outlined below are

the specific warranty periods and leval of coverage:

GSE-109 90 days parts

GSE-110 90 days parts

GSE-112 90 days parts

Warranty registration must be completed and received-

within 10 days of installation for warranty activation.

Warranty registration can be mailed by completing the

enclosed warranty card or can be completed at our

website; www.thelegacycompanies.com.

GE ERAL’s obligation under this warranty shall be lim-

ited to the repair or at the sole discretion of TLC

Technical Service, the replacement of the appliance.

Authorized on-site service is not authorized for these

appliances, however the end user may be directed to

take the appliance to the nearest authorized service

agency. In the event of a malfunction, GE ERAL will

not be held responsible for spoilage of products, loss of

sales or consequential damages. In the event a

replacement unit is to be supplied, TLC will cover all

costs to replace the defective product including associ-

ated shipping costs to deliver a new product to the cus-

tomer but only after satisfactory evaluation of the origi-

nal unit by an authorized TLC service agent. See the

back cover of this manual for all limited warranty

details.

GENERA IMITED WARRANTY PROVISIONS

Owner Information ...............................................1-2

General....................................................................1

Limited Warranty Provisions ...................................1

Servi e/Te hni al Assistan e ..................................2

General Product Information ..............................2-3

General Features .................................................2-3

Important Safety Information ..............................3-4

Specifications .......................................................5-7

Ele tri al Ratings ....................................................5

Ele tri al Cord & Plug Configurations.....................5

Weights and Dimensions .....................................6-7

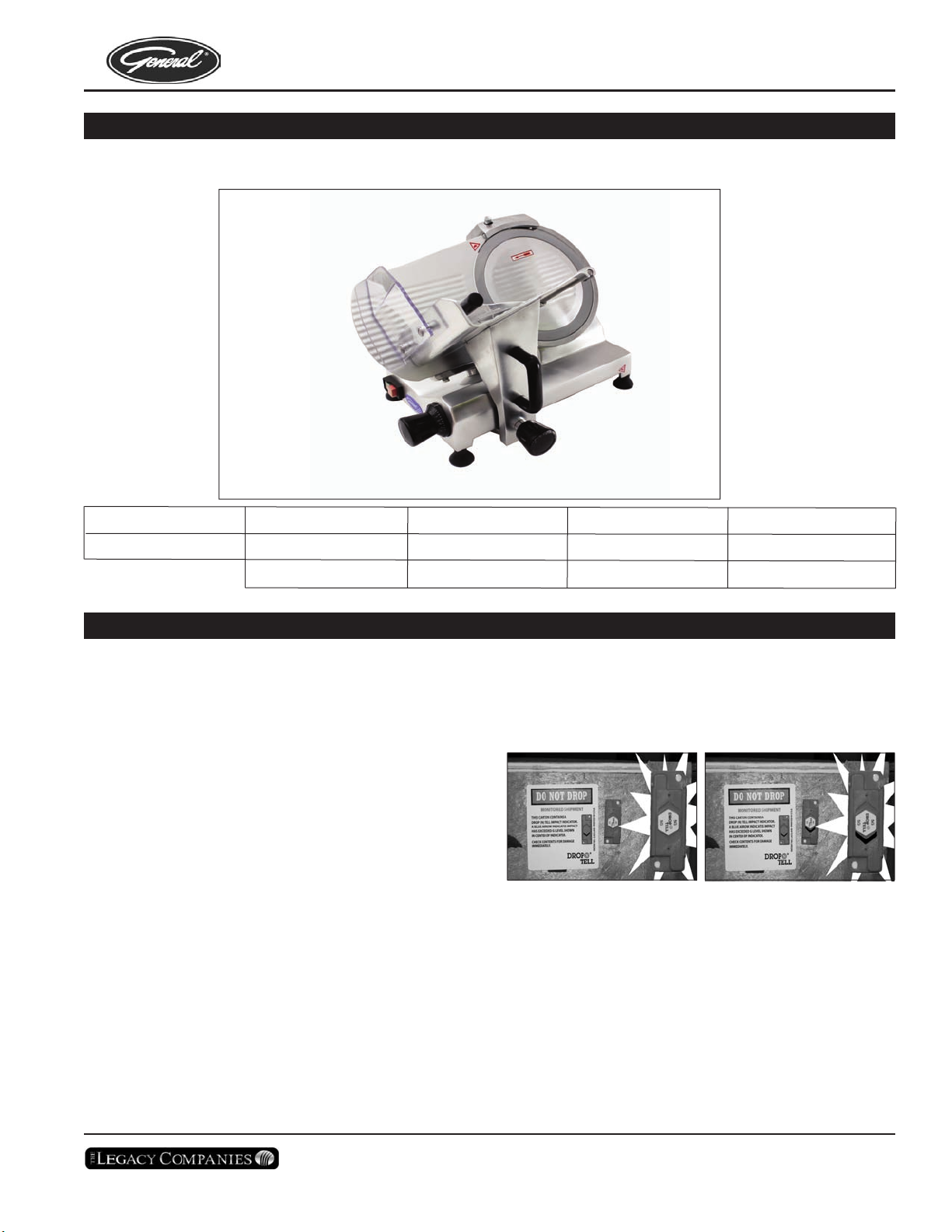

Recieving..................................................................7

Installation................................................................8

Unpa king ...............................................................8

Equipment Setup.....................................................8

Ele tri al..................................................................8

TAB E OF CONTENTS

Operation ............................................................9-12

Cleaning...............................................................10-11

Maintenan e........................................................11-12

Replacement Parts ...........................................13-17

GSE-110...........................................................13-15

GSE-112...........................................................16-17

Notes.......................................................................18