2

Laser Safety

• Use the tool only with the

specifically designated batteries.

• Store the tool out of reach of children and

other untrained persons. Laser tools are

dangerous in the hands of untrained users.

• Use only accessories that are

recommended for your model.

• Tool service must be performed only by

qualified repair personnel. Repairs, service

or maintenance performed by unqualified

personnel will void the warranty.

Only approved and authorised service

technicians can carry out warranty repairs.

• Do not use optical tools such as a telescope

or transit to view the laser beam. Serious

eye injury could result.

• Do not place the tool in a position which

may cause anyone to intentionally or

unintentionally stare into the laser beam.

Serious eye injury could result.

• Do not position the tool near a reflective

surface which may reflect the laser beam

toward anyone’s eyes. Serious eye injury

could result.

• Do not set up the tool at a position where

the laser beam can cross any person at

head height.

• Do not let children come in contact with

the tool.

• Turn the tool off when it is not in use.

Leaving the tool on increases the risk of

staring into the laser beam.

• Do not operate the tool around children or

allow children to operate the tool. Serious

eye injury may result.

• Position the tool securely on a level

surface. Damage to the laser or serious

injury could result if the laser falls.

• Do not remove or deface warning labels.

• Never look into the laser beam directly

and intentionally.

• Do not use optical tools to view the

laser beam.

• Do not set up the tool at a position

where the laser beam can cross any

person at head height.

• Do not let children come in contact

with the laser.

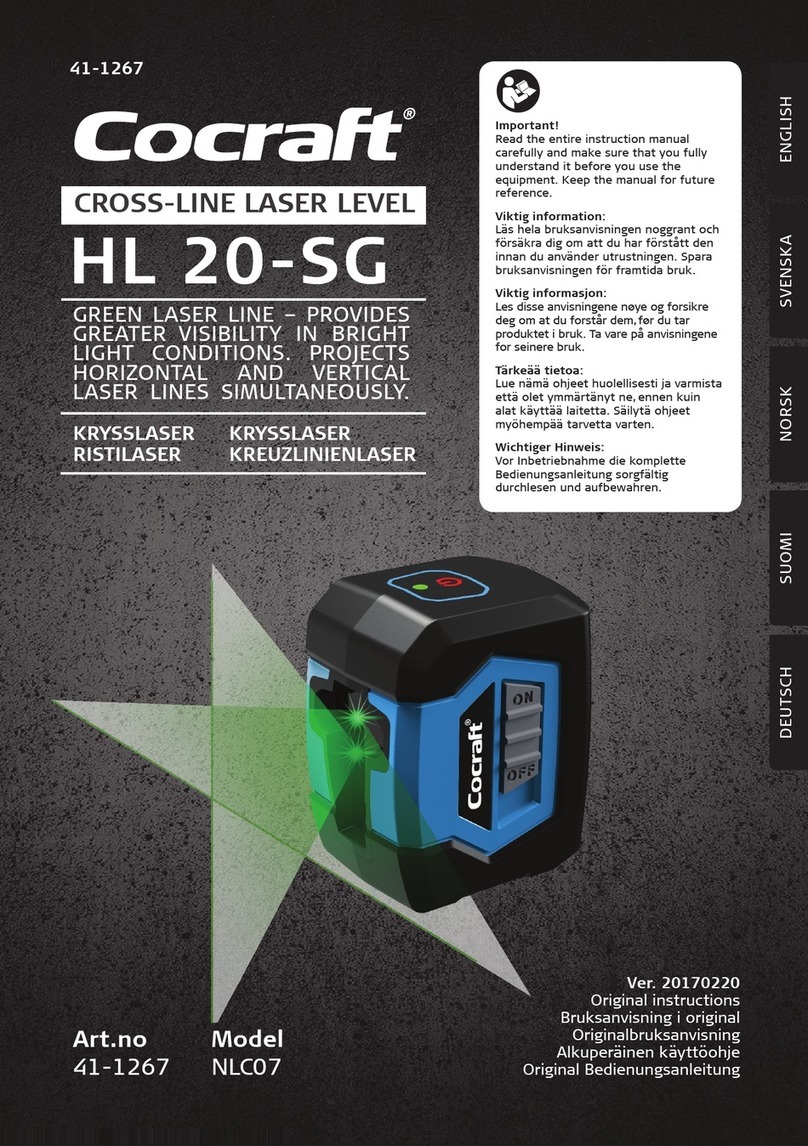

Read the following safety instructions before attempting to operate this tool.

Keep these instructions in a safe place or store in the carry pouch for future reference.

There are no user serviceable parts inside.

Disassembling the tool will void all

warranties on the product. Do not modify

the tool in any way. Modifying the tool may

result in hazardous laser radiation exposure.

CAUTION!

CLASS 2 LASER PRODUCT

WARNING! SAVE ALL WARNINGS & INSTRUCTIONS FOR FUTURE REFERENCE.

Read and understand all instructions.

!

!

WARNING!

DO NOT DISASSEMBLE THE LASER.