7

Using the Laser (continued)

OPERATION

Powering on

• Press the power button once and the laser level will

power on and begin automatically self-levelling.

When this levelling process is complete, the penta

prism inside the lighthouse will start rotating.

• If the laser level is outside the self levelling range

the laser level will not level causing the laser beam

to flash continuously.If this occurs, reposition the

laser level onto a level surface until the laser level

can level off.

In bright outdoor conditions, visible distance

will be significantly reduced. For outdoor use,

it is recommended to use the included detector.

Powering off

• Press the power button once and the laser level

will power off.

Speed control

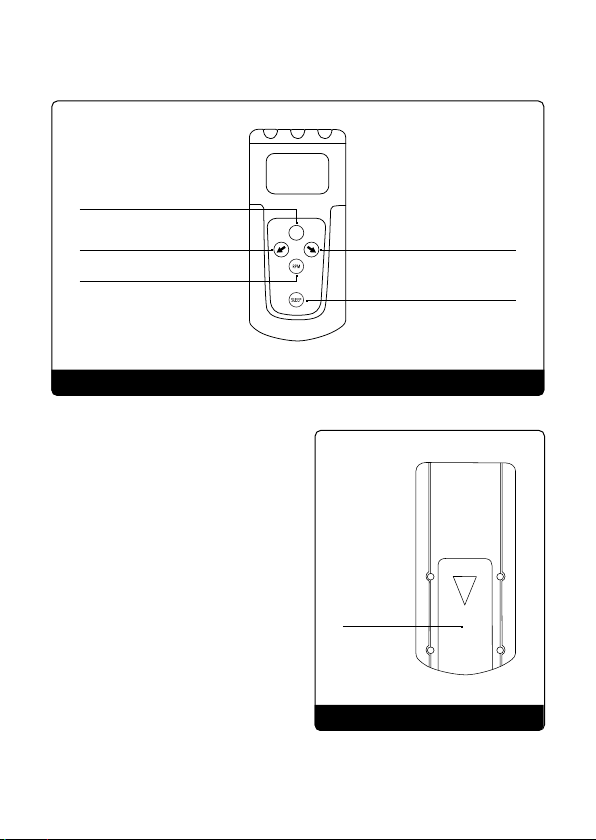

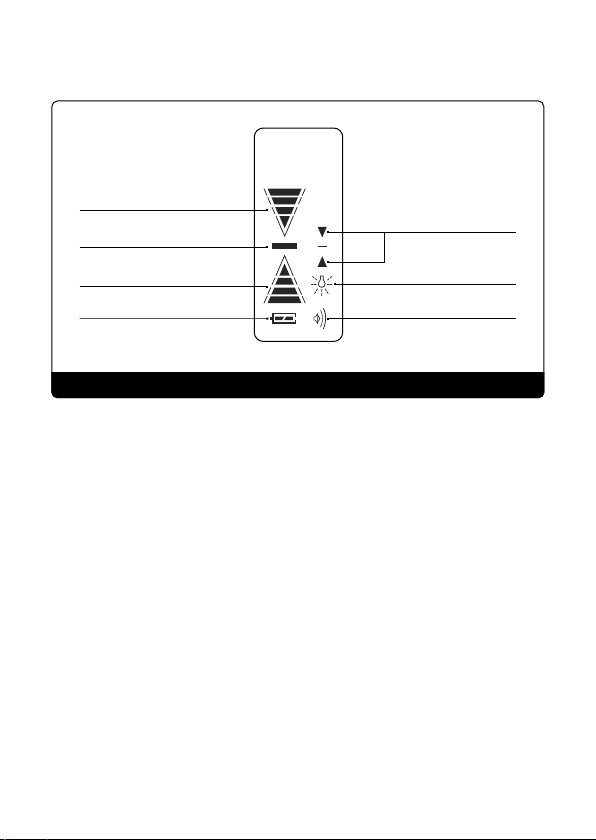

• Press the speed control button on the remote

control to cycle through various rotational speeds.

Sleep mode

• Press the sleep button on the remote control to

enter into sleep mode.

• The laser diode will stop spinning and shut off. (The

unit is not turned off in sleep mode).

• Press the sleep button on the remote control to

exit sleep mode.

After 60 minutes of inactivity during sleep

mode, the laser level will turn off automatically.

Tilt alarm

• Once the laser level has been levelled off the tilt

alarm can be enabled by pressing the tilt alarm

button.The tilt alarm indicator light will flash

continuously whilst active.

• If the laser level is disturbed while the alarm is

active the laser level will stop rotating and will

need to be powered off and on again to reset to a

level position.

Setting up a manual grade / slope

• To create a manual grade / slope, press the manual

grade mode button on the laser level control panel

or remote control.The laser level will now be in

manual mode with the X-axis active.The LED X / Y

axis indicator on the laser control panel will display

a solid light to indicate X-axis is selected.

• Press the grade adjustment arrow buttons on the

remote control.

• To change to the Y-axis, press the manual grade

mode button.The LED X / Y axis indicator on the

laser control panel will flash to indicate the Y-axis

is selected. The laser level can now be adjusted

on the Y-axis.

• Press the grade adjustment arrow buttons on the

remote control.

• To adjust the grade, press the manual grade mode

button to cycle between X andY axis

• To cancel manual grade mode, and return to

normal levelling press the power button off and on

again to reset the levelling process.

When in manual mode the laser level will

not self level and correct for vibrations and/or

disturbances.

Grade adjustments can only be made by

pressing the grade adjustment arrow buttons

on the remote control.