RECOGNIZE SAFETY INFORMATION. When you see this

symbol on your machine or in this manual, be alert to the

potential for personal injury,

Follow the recommended precautions and safe operating

practices.

UNDERSTAND SIGNAL WORDS. DANGER, WARNING

and CAUTION appear with the safety-alert symbol in this

manual and on safety labels on the machine to identify the

level of hazard seriousness.

DANGER indicates a hazard that WILL result in severe

personal injury or death.

WARNINGindicates a hazard or unsafe practice which

COULD result in severe personal injury or death.

CAUTION indicates hazards or unsafe practices which

COULD result in minor personal injury or equipment

damage.

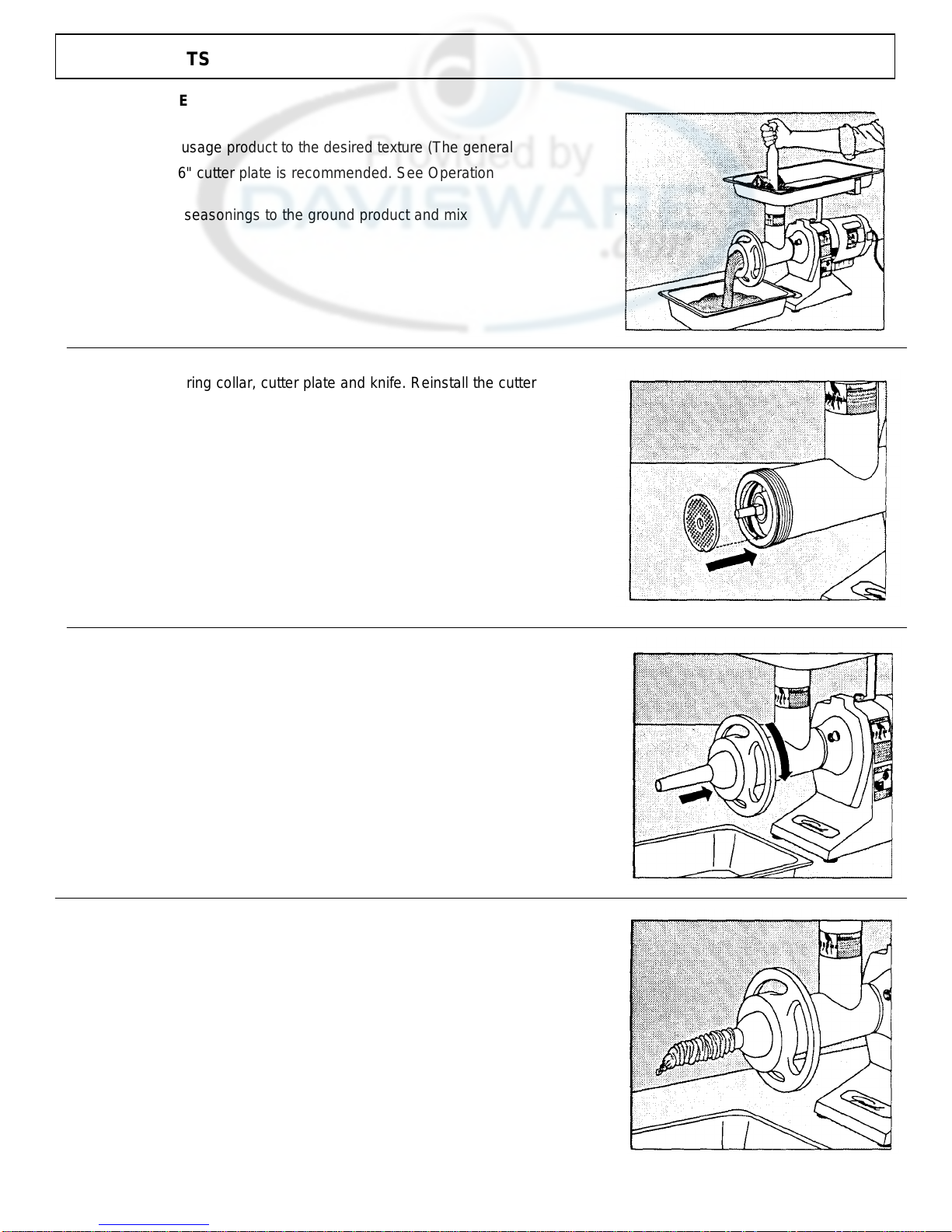

READ ALL INSTRUCTIONS

Read this operator's manual before using the machine.

Failure to follow the instructions provided could result in

personal injury or equipment damage.

KEEP OUT OF REACH OF CHILDREN

This chopper is intended for commercial use only.

Operators must be 18 years of age or older.

DO NOT FEED FOOD BY HAND.

Always use the foodpusher.

Always place the product to be ground on the tray.

DO NOT OPERATE IF DAMAGED

Do not operate this chopper with a damaged cord or plug, or

if the chopper has been dropped or damaged in any

manner. Contact the nearest factory-authorized service

center for examination, repair or adjustment. (Refer to the

service center list included in the Owner's Information

Packet.)

Do not allow the cord to touch hot surfaces.

Do not allow the cord to hang over the edge of a table or

counter.

Do not allow the cord near cutting board.

DO NOT LEAVE CHOPPER UNATTENDED.

UNPLUG CHOPPER

Set the switch to OFF and unplug the chopper from the

outlet when not in use and before cleaning or removing

jams.

KEEP MACHINE AWAY FROM WATER

Do not let machine base stand in water.

Do not immerse the chopper in water or any other liquid.

ATTACHMENTS

Do not use attachments not recommended by the

manufacturer.

Follow the manufacturer's instructions for use of

attachments.

SAVE THESE INSTRUCTIONS.

Keep this booklet in a convenient location for future

reference.

01.15.96

2