Specifications: #10-1440

Stock Number ............................................................................................................................ 10-1440 M1

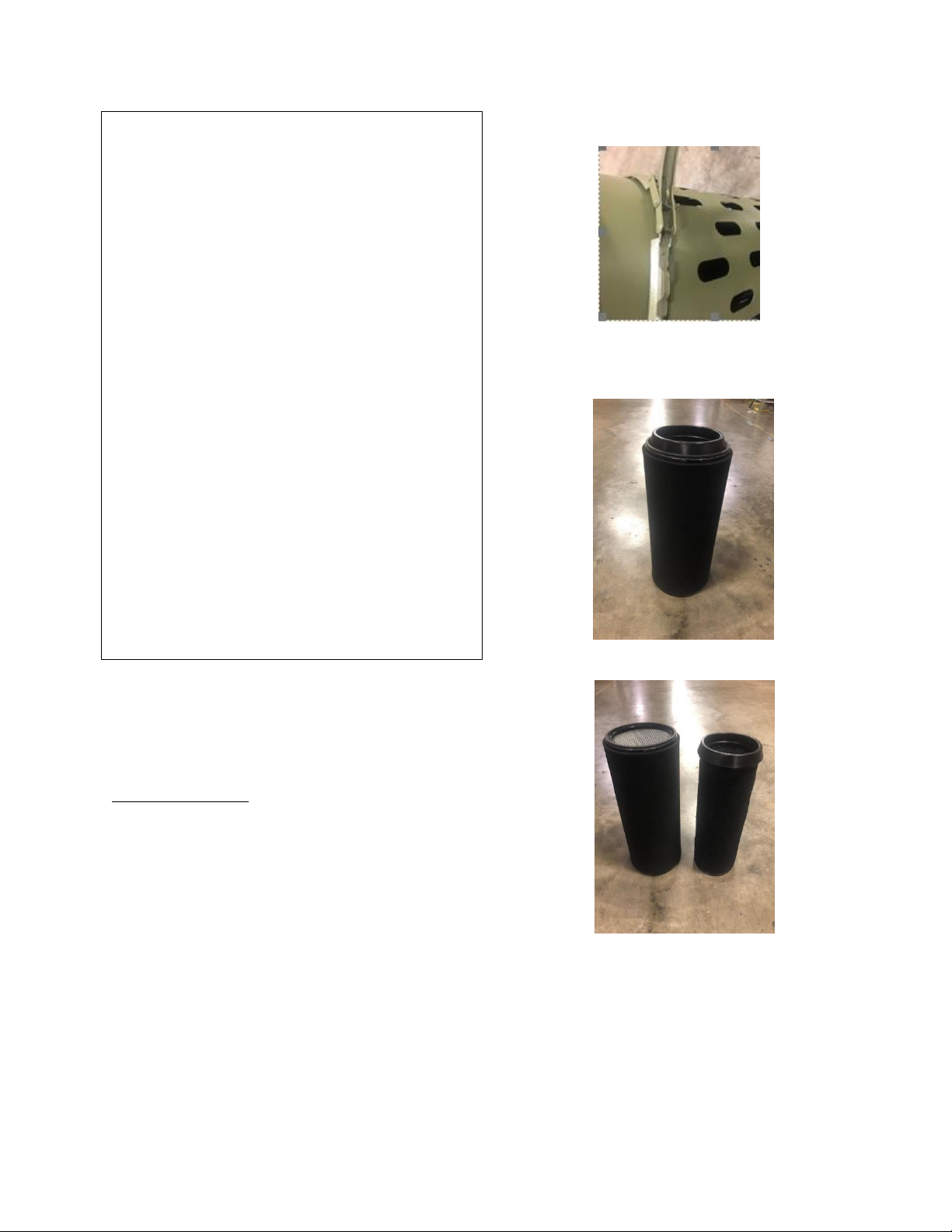

Outer Filter ................................................................................................................................... 5 Microns

Inner Filter ..................................................................................................................................... 1 Micron

Overall Dimensions (H/in x Diameter) .....................................................................................31-1/2” x 14”

Sound Rating @ 3ft .......................................................................................................... High Speed 75 dB

.................................................................................................................................... Medium Speed 69 dB

........................................................................................................................................... Low Speed 65 dB

Air Flow ..................................................................................................................... High Speed 1550 CFM

............................................................................................................................. Medium Speed 1260 CFM

...................................................................................................................................... Low Speed 980 CFM

Filter Cycle (min).................................................................................................................................... 2.06

Cycles per Hour (20’x20’x8’) ……………………………………………………………………………………………… 29.13 Cycles

Motor ................................................................................................................. 115V, 60Hz, 1 PH, 6P, 5.5A

Net Weight ......................................................................................................................................... 31 lbs.

Shipping Weight ................................................................................................................................. 34 lbs.

For Your Own Safety

1. Read and understand instruction manual before installing or operating air cleaner.

2. To reduce the risk of injury disconnect the air cleaner from the power source (unplug) before servicing

or changing filters.

3. If ceiling mounted, bottom of air cleaner must be at least 7 feet above the floor.

4. If ceiling mounted, mounts must be anchored to building structure which will support a minimum of

at least 100 pounds. Never mount to surfaces such as dry wall or false ceiling grids, etc.

5. To reduce the risk of electrical shock, do not expose air cleaner to water or rain.

6. Never duct a machine directly into the air cleaner.

7. To avoid a potentially dangerous situation, do not use this equipment to filter flammable vapors or

smoke. This air cleaner is designed and intended for the filtration of air borne wood dust only. It is

neither designed nor intended for any other purpose whatsoever.

8. Failure to comply may result in serious injury and / or property damage.

The above specifications were current at the time this manual was published, but because of our policy

of continuous improvement, GENERAL reserves the right to change specifications at any time and

without prior notice, without incurring obligations.