at the ambient atmospheric pressure during shipment no matter what the temperature.

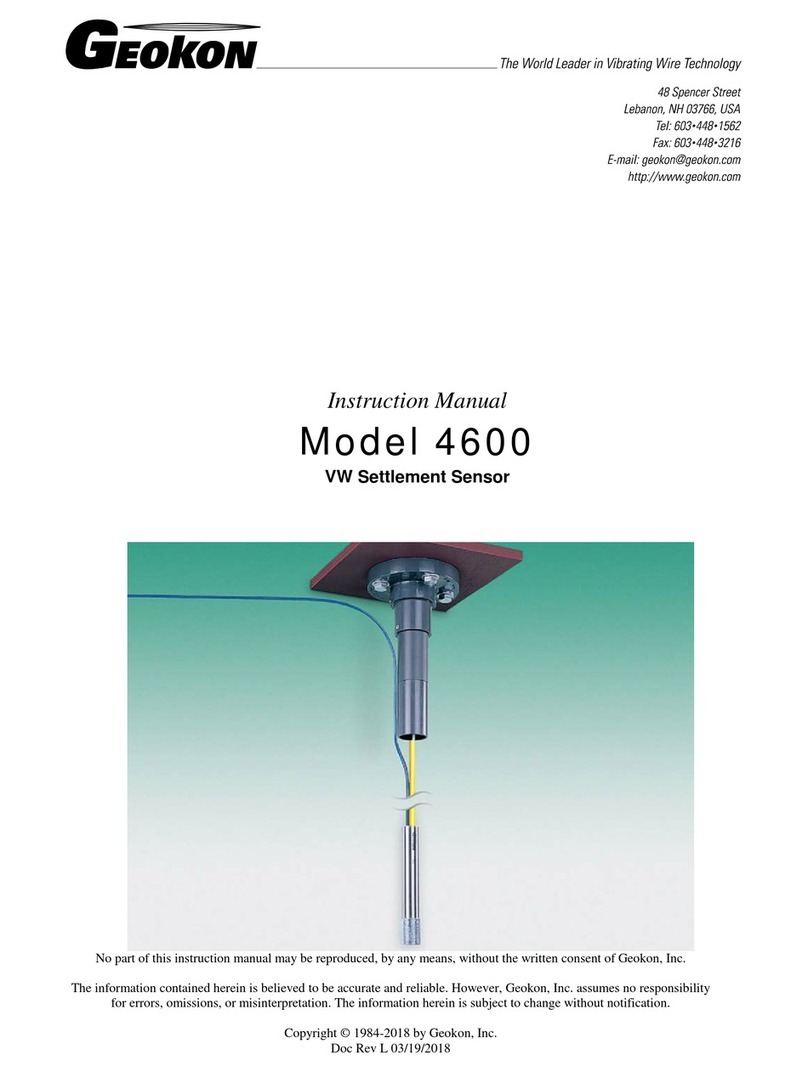

To put the 4600 system into service it is necessary, first, to grip the Swagelok cap holding the

travelling tube and pull the reservoir plug out of the top of the reservoir, (the larger of the two

Delrin plugs). Suck 10cc of liquid from the top of the reservoir using the syringe provided. (The

syringes provided have a capacity of 12cc). Add a few drops of light oil to the surface of the

liquid to prevent evaporation. Push the reservoir plug back into place and remove the cap

holding the travelling tube. Remove the other Swagelok cap and connect the short copper U-

tube supplied, with fittings, to the top of the reservoir and the top of the desiccant chamber.

Attach the settlement flange to the settlement plate using the bolts supplied.

While holding the reservoir in an upright position at all times, the settlement flange and plate

can now be attached to the reservoir using the two machine screws provided or by using PVC

cement obtained locally. (Federal Regulations prohibit the shipment of PVC cement). Apply

PVC cement to the inside of the reservoir extension (see Figure 2) and to the outside of the

top of the reservoir housing. Be careful at all times not to allow the reservoir to tip over on its

side which would allow liquid to enter the vent line.

Position the settlement flange at the top of the borehole and dig a trench leading from the

borehole to the readout location into which the signal cable can be buried. Avoid sharp bends

where the cable exits the borehole by excavating a broad sweep from the borehole to the

trench (see Figure 1).

Bury the signal cable in the trench using sand or other fine grain materials around the cable to

protect the cable from damage.

Terminate the signal cable inside a readout enclosure mounted on a post or pipe driven into

the ground at the readout location.

3. TAKING READINGS

Take the initial reading, R0, several times to ensure a good baseline reading. Read the

temperature also. An insitu calibration check, of sorts, can be made by raising the reservoir

flange by a measured amount and observing the change in readout thus produced. Compare

this calibration with the factory calibration. Alternatively, the initial gage reading, when

converted to a height of liquid column, should correspond with the known difference in

elevation between the reservoir and sensor.

Readings should be taken by a Model GK-403, GK-404 or GK-405 Readout Box set to display