I

TABLE OF CONTENTS

1. INTRODUCTION............................................................................................................................................1

1.1 THEORY OF OPERATION...............................................................................................................1

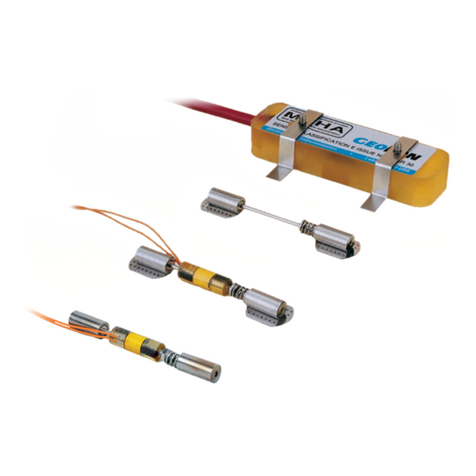

1.2 LOAD CELL DESIGN AND CONSTRUCTION ................................................................2

1.2.1 FRICTION BETWEEN THE BEARING PLATE AND LOAD CELL.......................................3

1.2.2 WARPING OF THE BEARING PLATES AND BEARING PLATE DESIGN ......................4

1.2.3 ECCENTRIC LOADING .....................................................................................................................4

1.2.4 ELASTIC BEHAVIOR .........................................................................................................................5

1.2.5 TEMPERATURE EFFECTS...............................................................................................................5

2. INSTALLATION..............................................................................................................................................6

2.1 PRELIMINARY TESTS......................................................................................................................6

2.2 LOAD CELL INSTALLATION .......................................................................................................6

2.2.1 TRANSPORTATION...........................................................................................................................6

2.2.2 INITIAL NO-LOAD READING.........................................................................................................6

2.2.3 INSTALLATION ON TIE-BACKS AND ROCKBOLTS .............................................................6

2.3 CABLE INSTALLATION AND SPLICING ..........................................................................6

2.4 ELECTRICAL NOISE ...........................................................................................................................7

2.5 ENVIRONMENTAL FACTORS ....................................................................................................7

2.6 LIGHTNING PROTECTION............................................................................................................7

3. TAKING READINGS .................................................................................................................................9

3.1 GK-404 VIBRATING WIRE READOUT................................................................................9

3.1.1 OPERATING THE GK-404 ...............................................................................................................9

3.2 GK-405 VIBRATING WIRE READOUT............................................................................ 10

3.2.1 CONNECTING SENSORS WITH 10-PIN BULKHEAD CONNECTORS

ATTACHED ....................................................................................................................................... 10

3.2.2 CONNECTING SENSORS WITH BARE LEADS................................................................... 10

3.2.3 OPERATING THE GK-405 ........................................................................................................... 10

3.2.4 READOUT IN LOAD UNITS........................................................................................................ 11

3.3 MEASURING TEMPERATURES ........................................................................................... 12

4. DATA REDUCTION ................................................................................................................................13

4.1 LOAD CALCULATION ................................................................................................................... 13

4.2 TEMPERATURE CORRECTION FACTOR ...................................................................... 14

5. TROUBLESHOOTING .......................................................................................................................... 16

APPENDIX A. SPECIFICATIONS .................................................................................................. 17

A.1 MODEL 4900 LOAD CELL SPECIFICATIONS.......................................................... 17

A.2 THERMISTOR...................................................................................................................................... 17