5

Section

3:

System Opera

t

i

o

n

Disconnect power source when not in use.

Double check 12V systems positive and negative are not reversed at any connection

p

o

in

t

.

Before turning the power switch

ON,

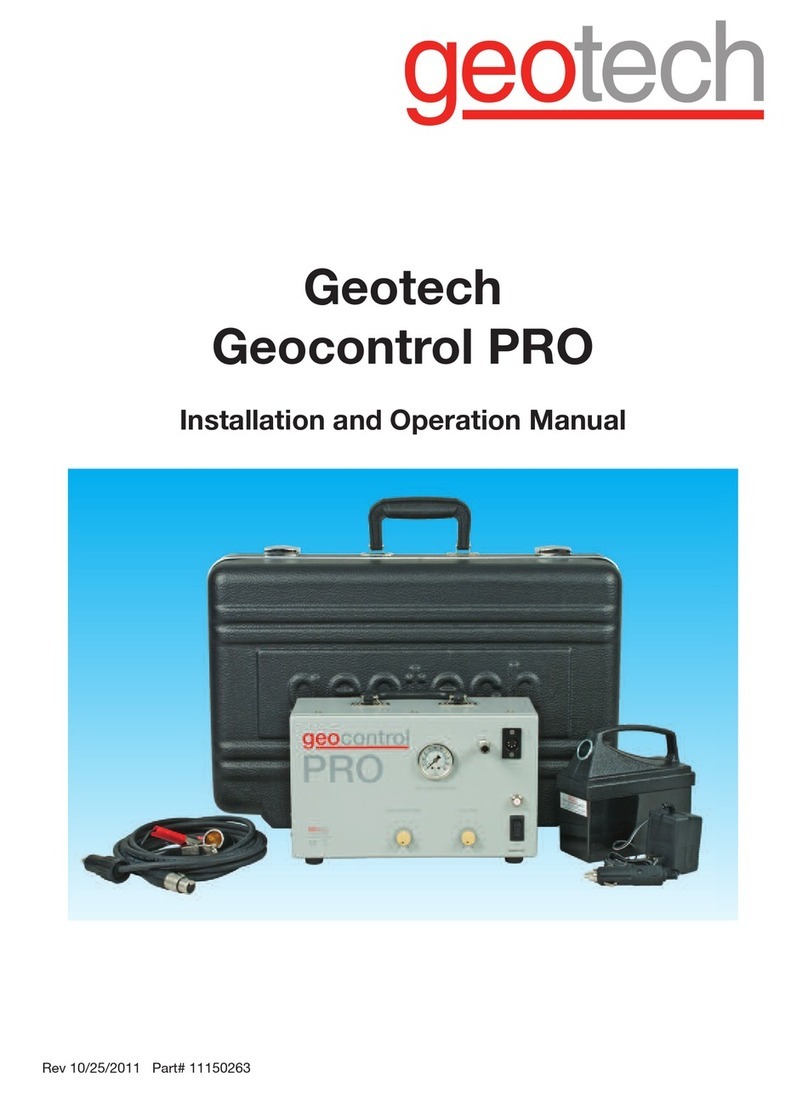

turn the Geocontrol PRO’s

FILL TIME

and

DISCHARGE

TIME

knobs to adjust the cycle times. Theseknobs are located on the front

face of the

Ge

o

c

o

n

t

r

o

l PRObelow the airline pressure gauge. To the left is DISCHARGE TIME

and to the right is FILL

TIME

. Use the radial number scales around each timer knob to adjust

timer values in s

e

c

o

n

d

s.

Discharge

Time

The discharge time is the time it takes to squeeze the bladder and push the water out of the

pump. Increase

t

his time with increased depth to water and larger bladder pumps. Decrease

this time with l

ow

e

r depth to water and smaller bladder pumps. Timer can be set from

approximately 2-75 s

e

c

onds

Fill

Time

The fill time is thetime allowed for the bladder to refill. Increase the fill time with more depth to

water

a

n

d

larger bladder pumps. Decreasethe fill time with less depth to water and smaller

b

l

a

dd

e

r pumps. The timer can be set from approximately 2-75 seconds. Fill rate depends on

hy

d

r

o

s

t

a

t

i

c

pressure

(

p

r

e

ssur

e

from the water above the

p

um

p

)

and varies depending on pump

p

l

a

c

e

ment within the water column; the more water above the pump the faster it will

f

ill.

Turn the controller power switch ON. When using longer fluid discharge lines, it could take

mul

t

i

p

l

e

cycles for water to reach the outlet. If the fluid discharge from the pump falls off before

the discharge cycle is complete, the discharge time is set too high. This could result in a

c

r

ea

s

e

d

bladder that will reduce per cycle pump volumes. Therefore, if the compressor is still runnin

g

and water has stopped coming out of the discharge tube, the discharge time should

b

e

decreased. Pumping efficiency can be maximized by measuring the amount of fluid

d

is

c

h

a

r

g

e

d

. If

the volume of fluid after one pump cycle is less than the rated volume of the pump

b

e

in

g

used,

then the fill rate can be in

c

r

ea

s

e

d

.