8

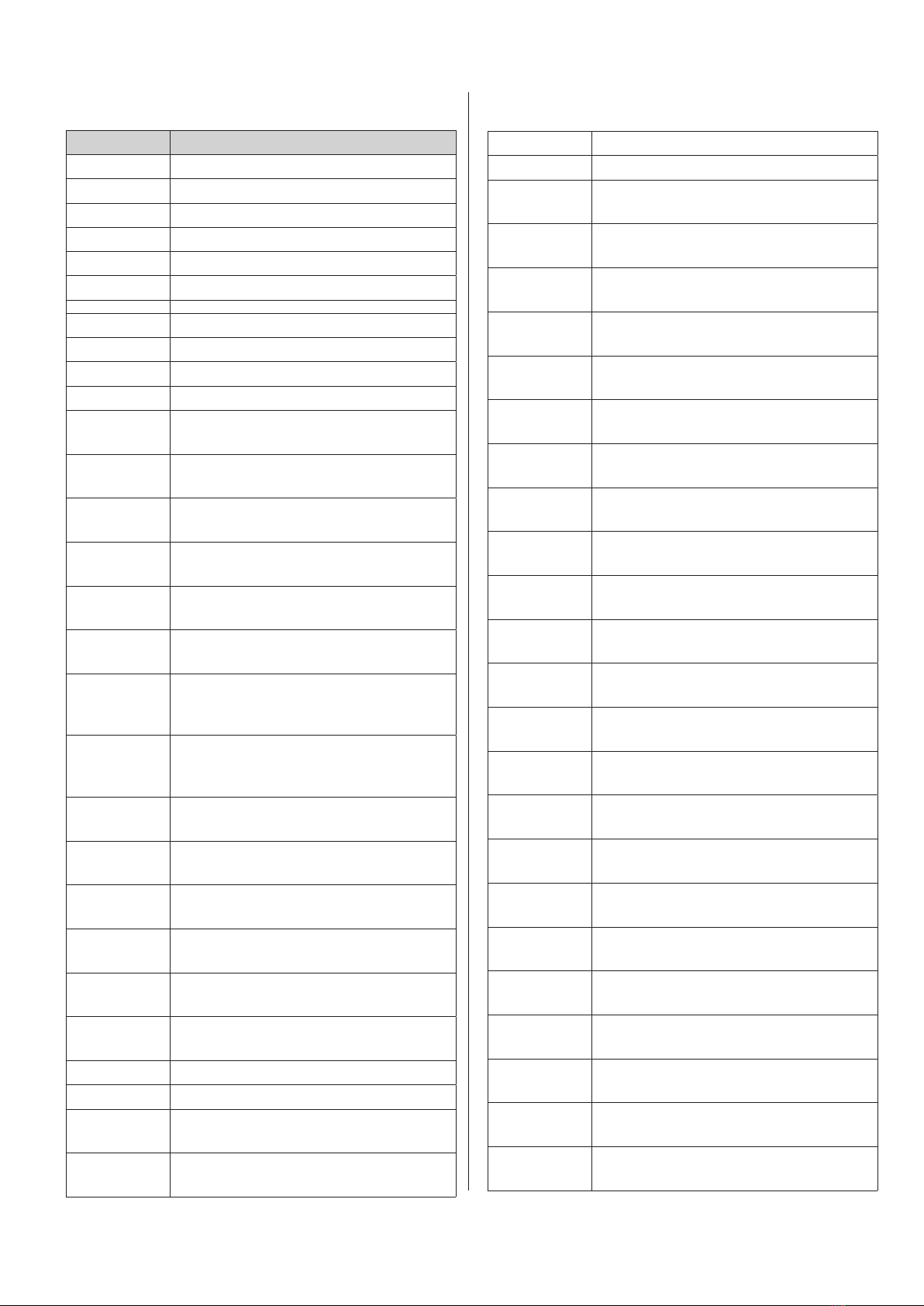

14.0 Spare part list

Art. No. Description

10-520 Table spring for 1490 mm PERMA arm

10-521 Wall spring for 1490 mm PERMA arm

10-525 Tight damper - ø57 mm

10-526 Tight damper - ø76 mm

10-527 Tight damper, ESD - ø57 mm

10-528 Tight damper, ESD - ø76 mm

10-316 Hood ø380 mm, polycarbonatee, ø57

10-416 Hood ø380 mm, polycarbonatee, ø76

10-316A Hood ø280 mm, polycarbonatee, ø57

10-416A Hood ø280 mm, polycarbonatee, ø76

10-317 Hood conical ø250 mm, polycarbonate,

ø57

10-417 Hood conical ø250 mm, polycarbonate,

ø76

10-318 Hood conical ø250 mm, polycarbonate,

m. flexrør 300 mm, ø57

10-418 Hood conical ø250 mm, polycarbonate,

m. flexrør 300 mm, ø76

10-319 Hood conical ø250 mm, polycarbonate,

straight edge, ø57

10-419 Hood conical ø250 mm, polycarbonate,

straight edge, ø76

10-320 Hood conical ø250 mm, polycarbonate,

m. flexrør 300 mm straight edge, ø57

10-420 Hood conical ø250 mm, polycarbonate,

m. flexrør 300 mm straight edge, ø76

10-321 ALU Hood conical ø150 mm, ø57

10-421 ALU Hood conical ø150 mm, ø76

10-366 ALU Hood conical ø150 mm, ESD, ø57

10-466 ALU Hood conical ø150 mm, ESD, ø76

10-323 Hood 340x250 mm, polycarbonate, ø57

10-425 Hood 340x250 mm, polycarbonate, ø76

10-324 Suction Pen L:250 mm, ALU, ø57

10-422 Suction Pen L:250 mm, ALU, ø76

10-367 Suction Pen L:250 mm, ALU, ESD, ø57

10-467 Suction Pen L:250 mm, ALU, ESD, ø76

10-325 Suction Pen L:350 mm, ALU, ø57

10-423 Suction Pen L:350 mm, ALU, ø76

10-368 Suction Pen L:350 mm, ALU, ESD ø57

10-468 Suction Pen L:350 mm, ALU, ESD, ø76

10-324A Suction press flange L:250 mm, ALU,

ø57

10-422A Suction press flange L:250 mm, ALU,

ø76

10-367A Suction press flange L:250 mm, ALU,

ESD, ø57

10-467A Suction press flange L:250 mm, ALU,

ESD, ø76

10-325A Suction press flange L:350 mm, ALU,

ø57

10-423A Suction press flange L:350 mm, ALU,

ø76

10-368A Suction press flange L:350 mm, ALU,

ESD, ø57

10-468A Suction press flange L:350 mm, ALU,

ESD, ø76

10-326 Suction Pen L:150 mm w/ flextube 300

mm, ALU, ø57

10-424 Suction Pen L:150 mm w/ flextube 300

mm, ALU, ø76

10-369 Suction Pen L:150 mm w/ flextube 300

mm, ALU, ESD, ø57

10-469 Suction Pen L:150 mm w/ flextube 300

mm, ALU, ESD, ø76

10-326A Suction press flangeL:150 mm w/

flextube 300 mm, ALU, ø57

10-424A Suction press flange L:150 mm w/

flextube 300 mm, ALU, ø76

10-369A Suction press flange L:150 mm w/

flextube 300 mm, ALU, ESD, ø57

10-469A Suction press flange L:150 mm w/

flextube 300 mm, ALU, ESD, ø76

10-370 Suction Pen L:150 mm w/ flextube 600

mm, med spjæld, ALU, ø57

10-371 Suction Pen L:150 mm w/ flextube 900

mm, med spjæld, ALU, ø57

10-329 Sugetragt oval 140x180 mm, polycar-

bonate, ø57

10-382 Sugetragt oval 140x180 mm, painted

polycarbonate, ESD, ø57

10-374 Hood, ø380 mm, painted polycarbona-

te, ESD, ø57

14.0 Spare part list