2. NOTES ON USAGE

2

CAUTION

For safety reasons, be sure to ground the unit by connecting the ground wire to a grounded terminal.

3. SPECIFICATIONS

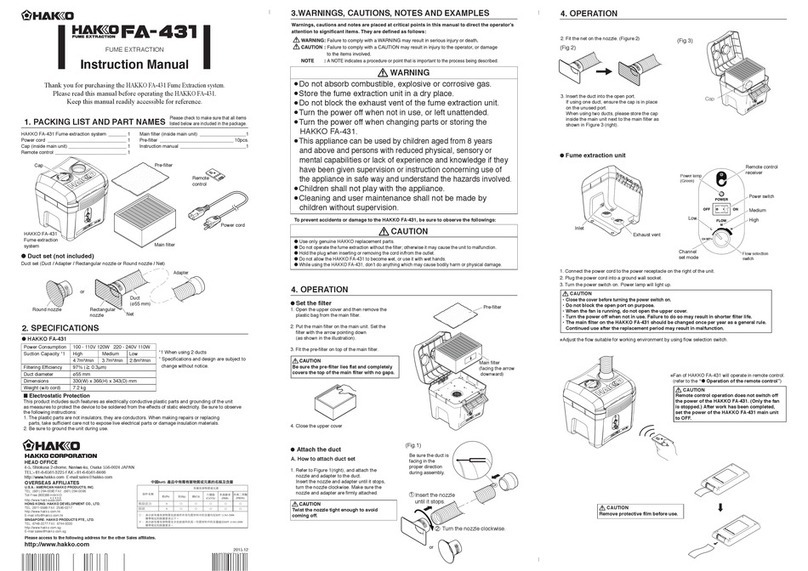

Model No. HAKKO 494

l Station

Part Name Station

Frequency 50 Hz 60 Hz

Power Consumption 150 W 200 W

Static Pressure 2.3 KPa (240 mmAq.) 3.2 KPa (325 mmAq.)

Absorption Capacity 1.56 m3/min. 1.82 m3/min.

Dimensions

(W x H x D)

322 x 300 x 386 mm

(12.68 x 11.81 x 15.2 in.)

w/o handle, cord

Weight 18 kg (39.9 lb.)

*Specifications and design are subject to change without notice.

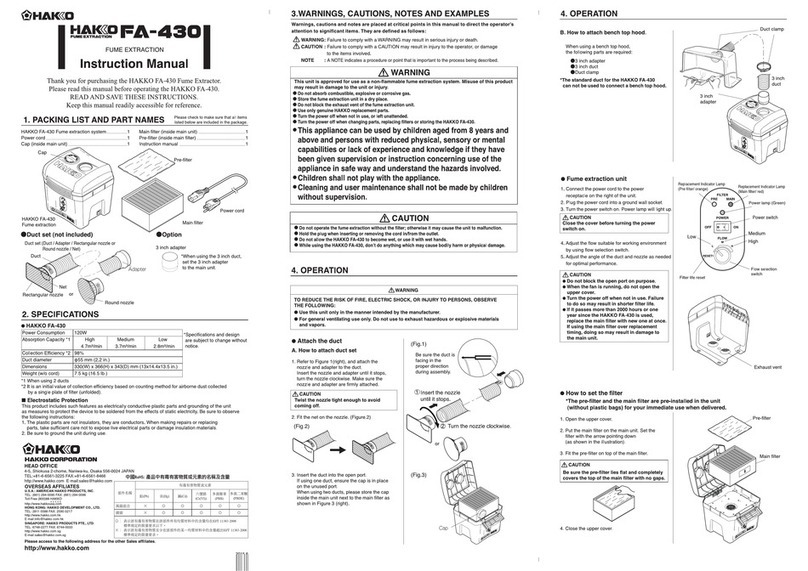

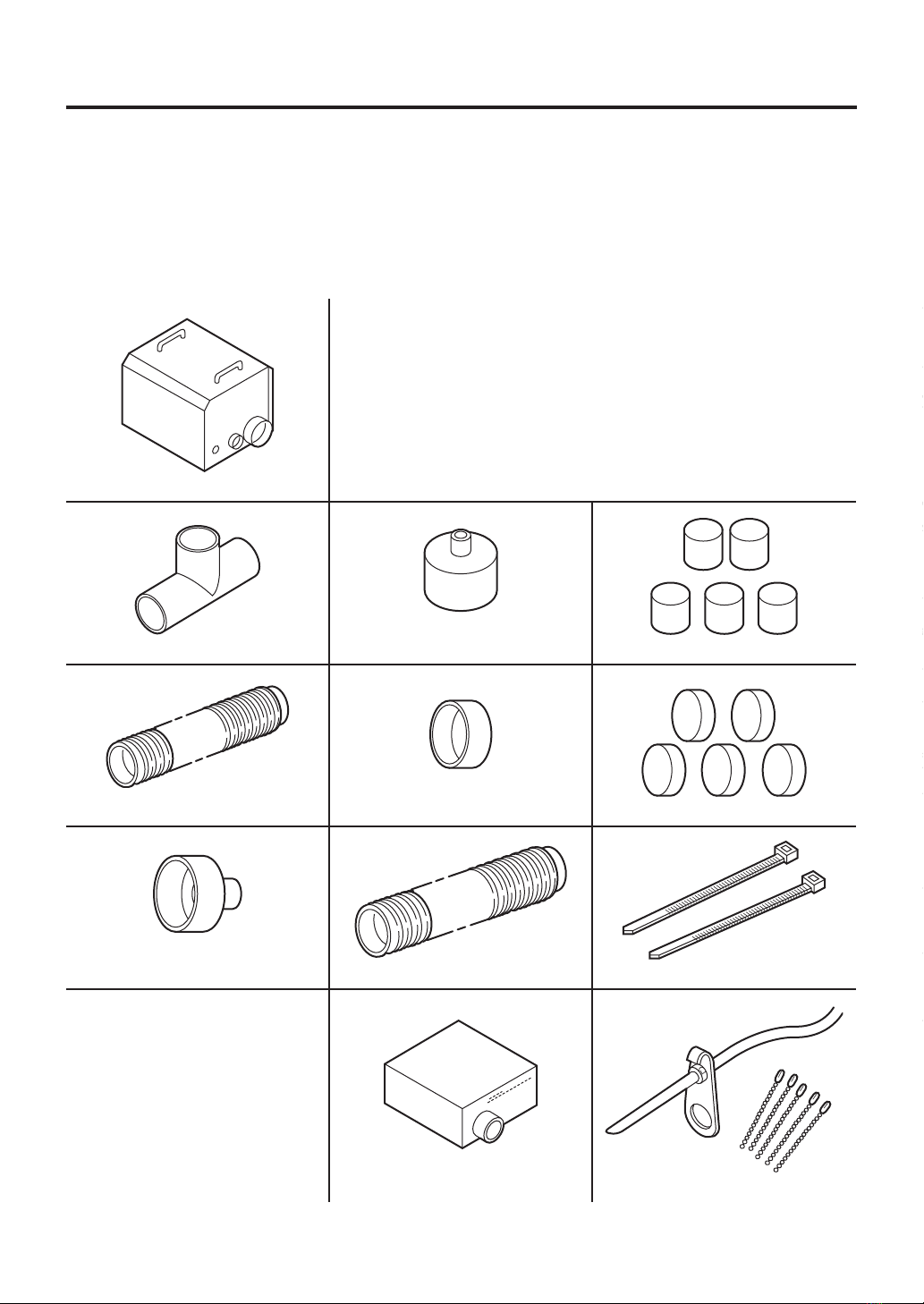

l Replacement Parts

Part No. Name Contents

C1028 Duct Set

Filter cap ...........................1

Pre-filter ............................5

Nylon strap .......................2

Filter strap......................... 1

Duct/1.5 m (4.92 ft.) ..........1

Part No. Name / Specification Contents

C1029 Absorption pipe set A/

DASH, 900M/L

Absorption pipe ....................... 1

Silicone hose/1 m (3.28 ft.) ...... 1

Hose coupling band ................. 5

Metal fitting for absorption pipe

... 1

C1030 Absorption pipe set B/

DASH, MACH-I (920, 921, 922)

C1031 Absorption pipe set C/

MACH-I (918)

C1033 Absorption pipe set E/

MG30 W – 100 W

C1034 Absorption pipe set F/455

C1035 Absorption pipe set G/456

C1086 Absorption pipe set H/902, 904 H contains cap nut (1) and Wave

washer (1), additionally.

C1540 Absorption pipe set R

Absorption pipe ....................... 1

Silicone hose/1.5 m (4.92 ft.) ... 1

Hose coupling band ................. 5

Metal fitting for absorption pipe ... 1

l Replacement Parts

Part No. Part Name/Specification

B1276 Filter cap

A1074 Pre-filter/5 pcs.

B1278 Filter case

B1292 Nylon strap/2 pcs.

B1279 Duct/1.5 m (4.92 ft.)

B1293 Duct/3 m (9.84 ft.)

B1277 End cover

B1280 Absorption pipe A/6.5 x 100 , DASH, 900M/L, MACH-I

B1281 Absorption

pipe

B/6.5 x 130 , 455, 457, 458

B1282 Absorption

pipe

C/6.5 bent, MG30 W- 100 W

B1283 Absorption

pipe

D/6.5 x 140 , 456

B1596 Absorption

pipe

E/6.5 x 80 , 902, 904

B1953 Absorption

pipe

/6.4 bent, 907, 908

B1284 Metal fitting for absorption pipe A/

DASH, 900M/L, 457, 458, 902, 904

B1285 Metal fitting for absorption pipe B/MACH-I (920, 921, 922)

B1286 Metal fitting for absorption pipe C/MACH-I (918)

B1287 Metal fitting for absorption pipe D/MG 30 W – 100 W

B1288 Metal fitting for absorption pipe E/455

B1289 Metal fitting for absorption pipe F/456

B1291 Silicone hose/1 m (3.28 ft.)

B1314 Silicone hose/E.S.D., 1 m (3.28 ft.)

B2184 Silicone hose/1.5 mm (4.92 ft.)

B1290 Hose coupling band/5 pcs.

B1294 Exhaust duct/5 m (16.4 ft.)

A1069 Main filter/5 pcs.

B1239 Timing belt

B1245 Inlet socket

B1246 Pararell piping joint

C1026 Suppressor

B3246 Metal fitting for absorption pipe R

Maintenance

Be sure to regularly replace all

expendable parts and clean

the required areas. (Refer to

“6. MAINTENANCE, PARTS

REPLACEMENT” on Page 6.)

Unless specifically requested to

do otherwise, always turn off the

power switch and unplug the power

cord from the power source before

beginning any maintenance.

Tip Temperature

The tip temperature drops slightly

when the smoke absorber is in

use. In workplaces where strict

temperature control is required,

measure the tip temperature (using

our products (thermometer)) 10

minutes after operating the smoke.

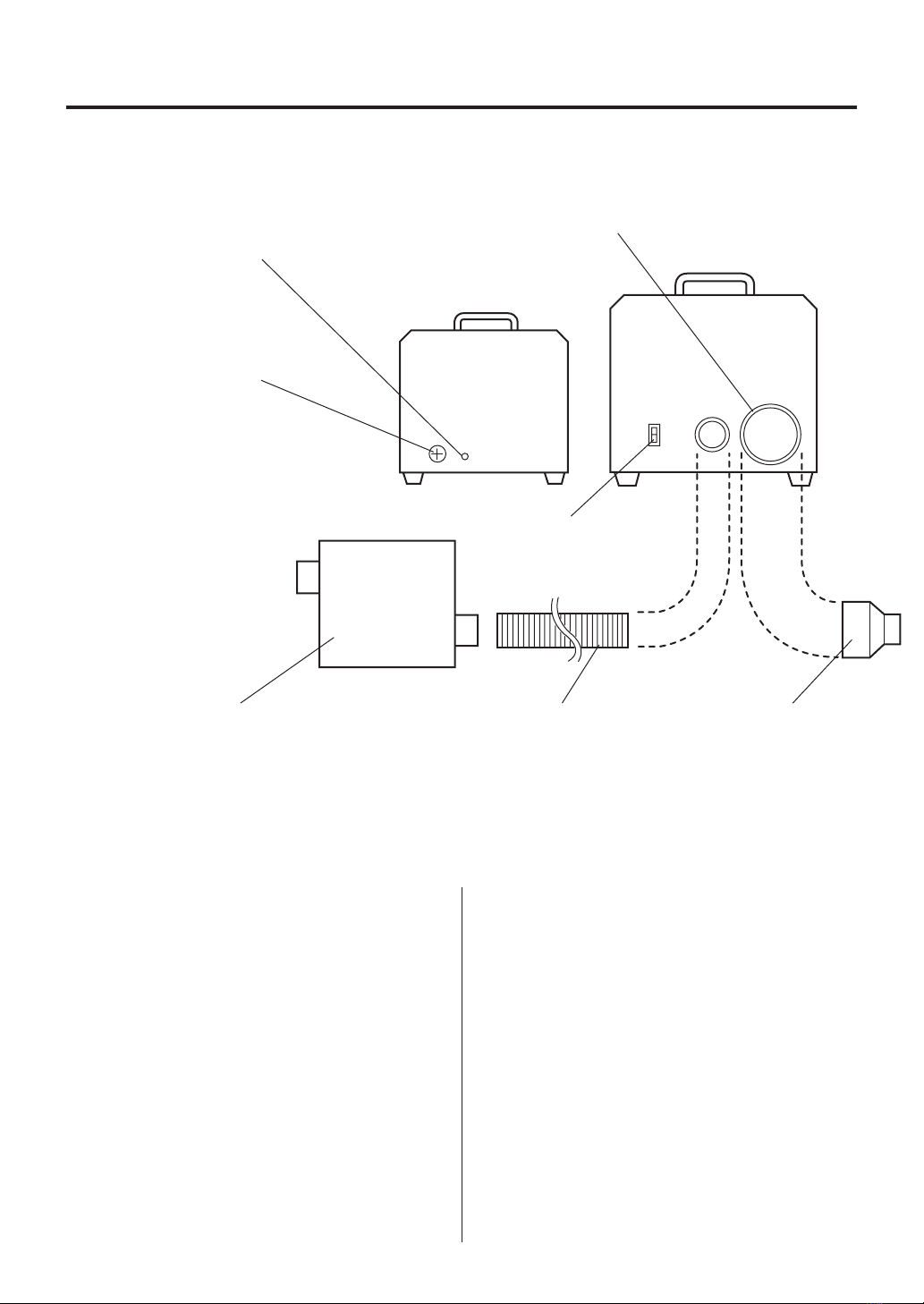

Soldering Iron

A single HAKKO 494 unit can

handle up to 10 soldering irons.

Filter

Operating the smoke absorber

without inserting filter may cause

the turbo fan to malfunction.

Always run the system the filter in

place.

Duct

The duct should be a maximum

of 20 m (65.6 ft.) in length on the

suction side and 5 m (16.4 ft.) in

length on the exhaust side.