5

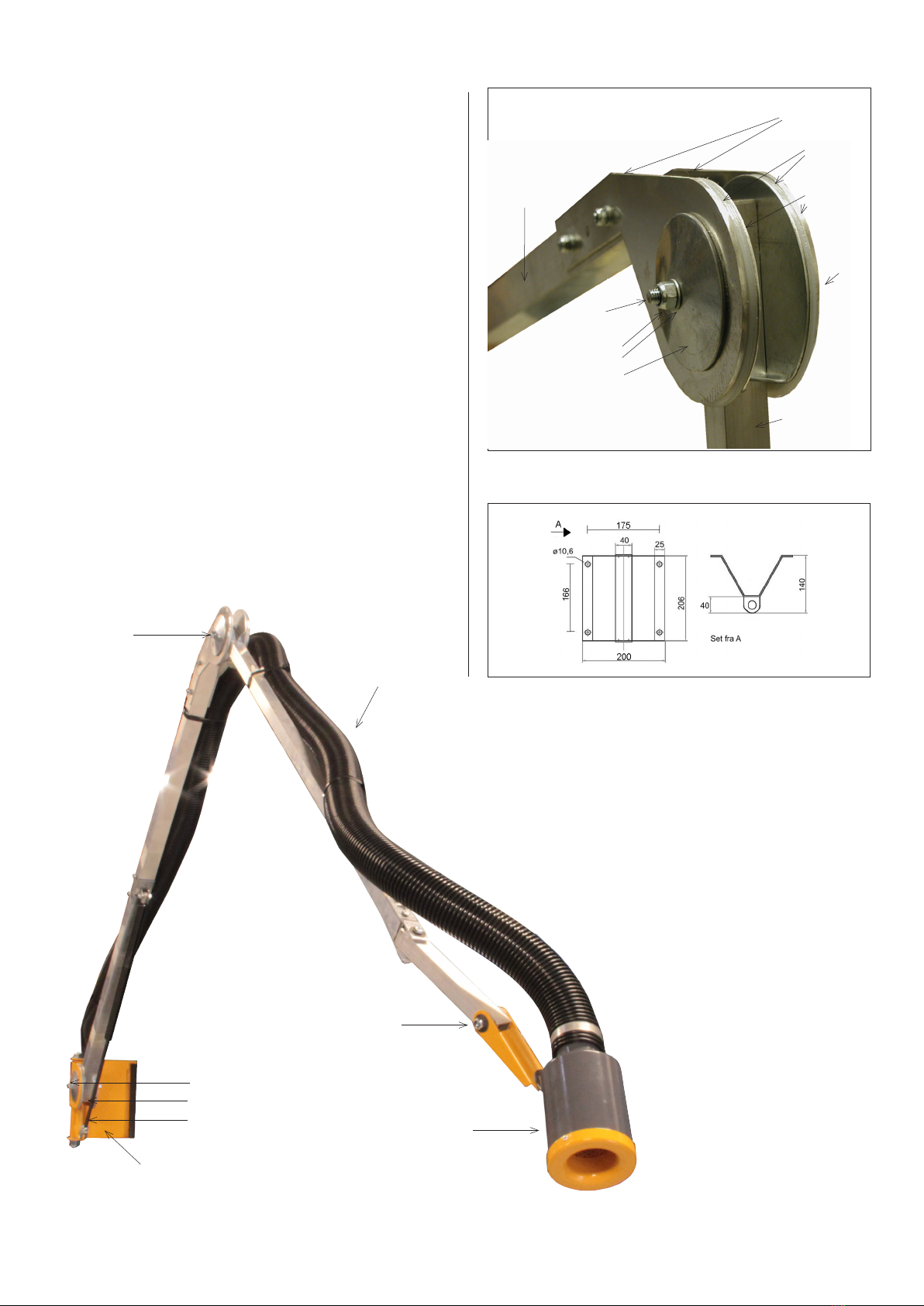

Recommended installation height HV50 arm: 2500

mm

Procedure:

1. The wall bracket is firmly attached to the wall by

means of 4 off 10 mm bolts. (When using the exten-

sion arm, please fix this bracket first – refer to item

2.1)

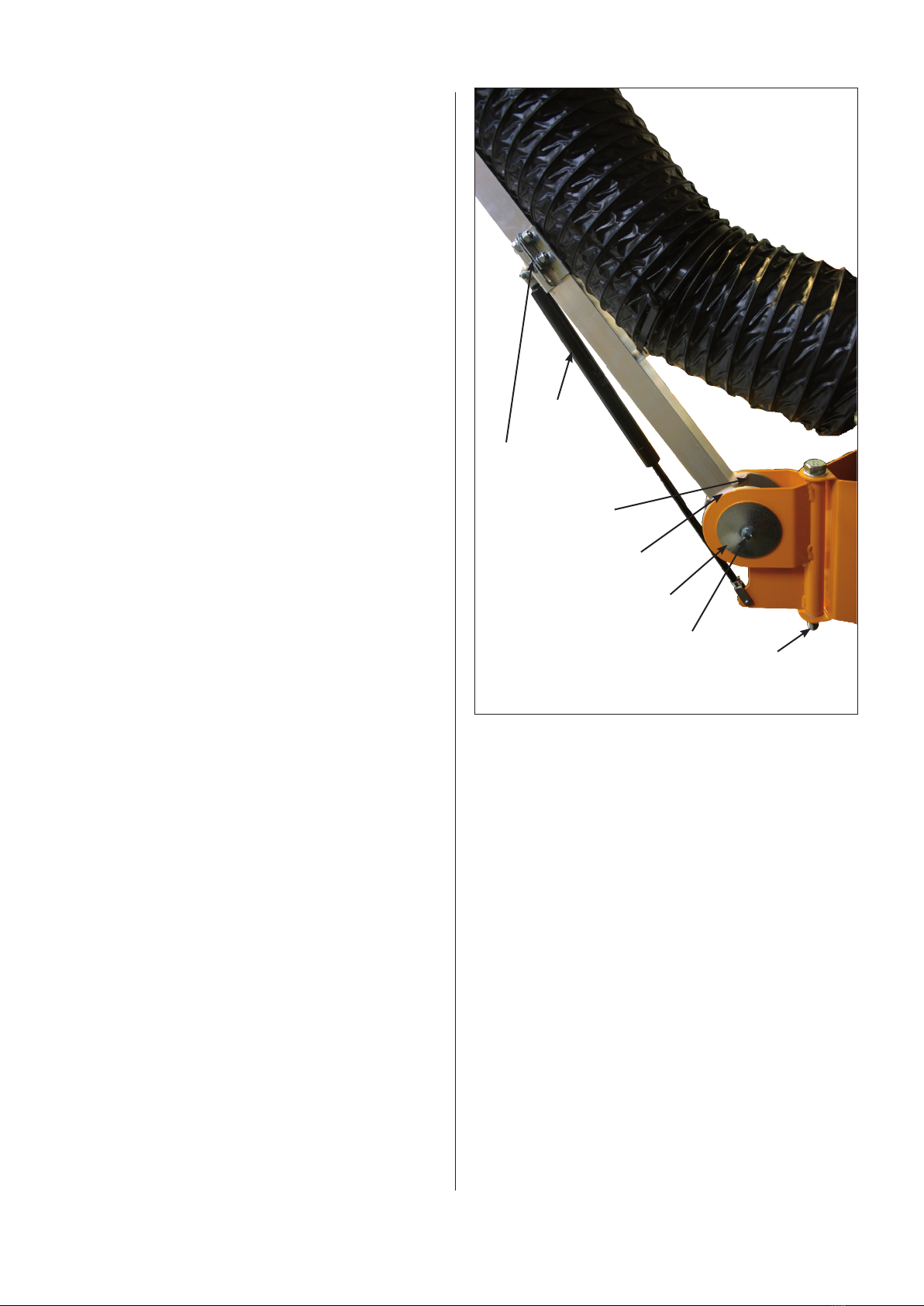

2. Mount the Arm on the wall bracket with the M16

bolt and friction discs. Make sure to fasten it in such

way that the Arm is easily rotated. If the inner joint/

arm hasn’t the wanted friction, the bell washer can

be loosen or tighten, or by adjusting the spring re-

tainer (against the wall to tighten – away from the

wall to loosen).

3. Center wrist checked and tightened if needed. Tigh-

ten the joint so that the arm moves freely, but also

so fast that it can sustain itself in a slightly bent

position.

4. Mount the funnel on the outer joint by taking the

supplied M8 bolt through 3 disc springs, the alu

half, the friction disc, the other alu half and the 3

disc springs and fasten them with an M8 lock nut.

5. The hose is mounted on the funnel by tightening the

clamp around the funnel and the hose. Now pull out

the hose to max. so that the least possible resistan-

ce is left in the hose and fasten with the enclosed

plastic binders. Subsequently, the hose is mounted

on the branch pipe by means of the clamp.

2.1 Mounting of optional equipment

Mounting of extension arm

The extension arm for HV50 is available in 1.0 m, 2.5

m and 4.0 m. (4,0 m available in both 1 and 2 line

arm).

1 m extension

Fixing the extension arm to a solid wall, in the same

way as the wall bracket in the section. 2.0.

Then fastened HV50 arm to the extension arm.

2.5 and 4.0 m extension

Attach the wall bracket.

Then install the extension arm

At 4.0 meters 2-leds mounted inner part, then mid link

and eventually outer loops. Ensure that the outer part

is positioned properly during assembly - tube holders

must face up.

Then attach the ducts to the extension arm with the

self-carving screws. The distane between the duct as-

sembled using a Clamp and the hose. The arm is then

fastened to the extension arm.

2.2 Trial run – exact adjustment

After the final mounting, the Arm should be adjusted to

the typical working area, for optimum utilisation of the

Arm. Do so by adjusting the rotary joints mentioned in

item 2 by means of 2 off 13 mm fixed spanners.

3.0 User instruction – application

Operated by the hood. Do not use the arm or hose.

Be especially aware that it is possible to squeeze your

fingers at the gas spring.

Move the hood to the wanted position and wait for the

friction discs to locked the arm.

In normal use, the arm can lift it self in the wanted positi-

on. The arm can rotary 270oin the working space.

The hose can be damaged and leaky by not using it

right, for example a screwdriver. This should be avoided

to ensure a long life span.

Always check that the correct volume of air is extracted

by the suction head/funnel.

Spring damper

Inner joint

ø114 friction bushing

ø80 bell disc

M8 bolt

M16 bolt with friction bushing

Adjustable spring retainer

Adjustable angle of attack