5

5.0 Assembly, installation and start of

operation

5.1 Location

To ensure a flawless function, the product must be in-

stalled indoors in e.g. an engineering room with sound

ventilation.

Outdoor installation is not recommended, and a canopy

must always be used as a minimum if indoor installation

is not possible.

We do not recommend outdoor installation, as the risk

of water and condensation in the product increases, and

the electronic components do not function at temperatu-

res below 5°C.

Before installing the product, ensure that an optimal lo-

cation is chosen. Is there enough space for the product?

Is there space for maintenance and filter changes?

Place the product on a level and stable base (e.g. a con-

crete concrete floor) and secure it.

Avoid as far as possible bends immediately before the

inlet and after the outlet, as this could reduce the perfor-

mance of the product.

5.2 Installation

The following installation should only be carried out by a

trained installer.

5.2.1 Installation

Procedure:

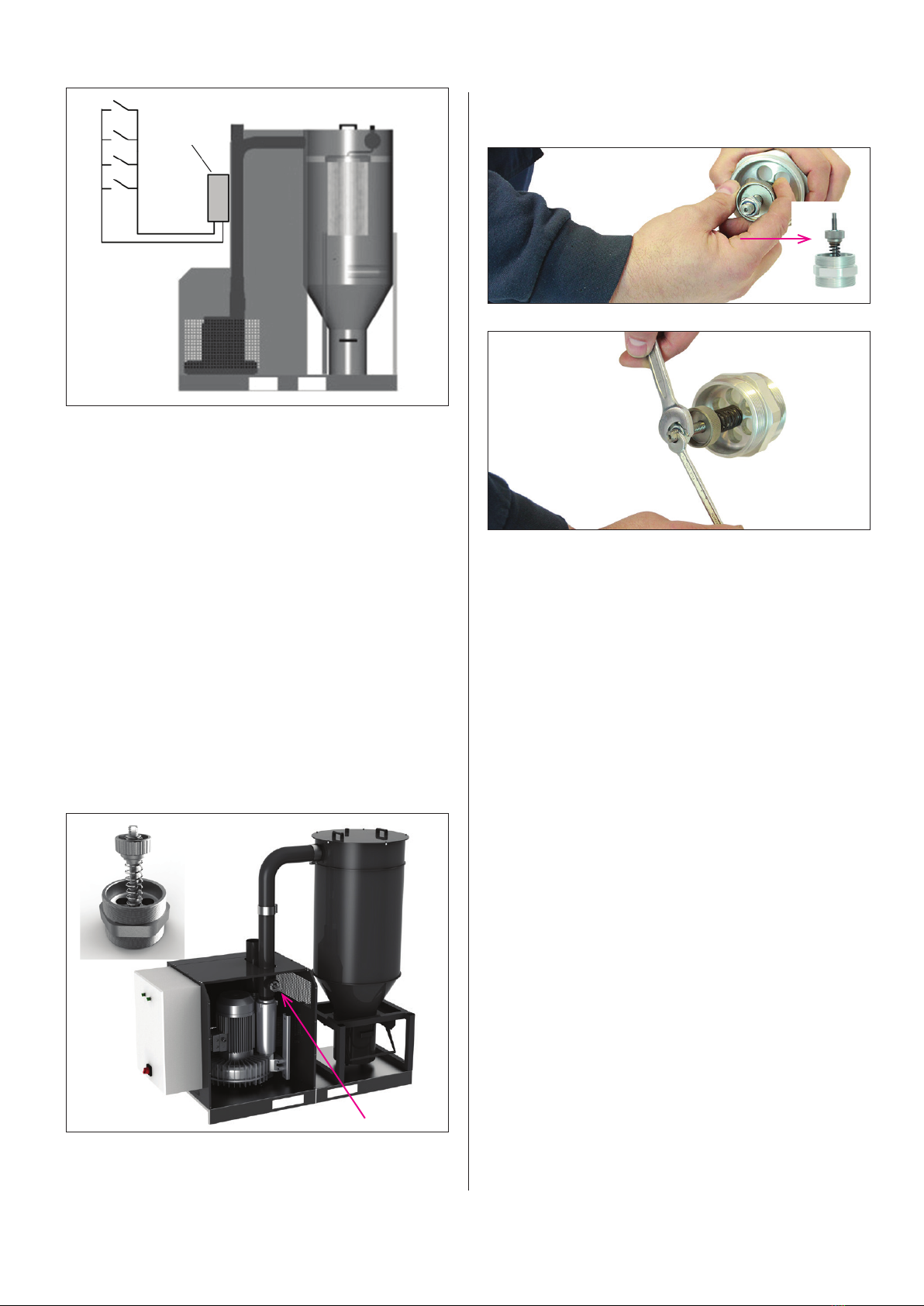

1. Place the HVU Lite on a solid foundation (e.g. a con-

crete floor) where there is no possibility for vibrati-

ons to be transmitted. In addition, allowance shall be

made for filter changes (i.e. minimum headroom of

800 mm).

2. The piping is connected to the HVU Lite. On the inlet

side the pipe can be fixed e.g. by means of a snap

lock system.

Remember to seal the joint with sealant and/or tape!

3. To ensure free mixing, the discharge should be di-

rected two meters above the roof ridge towards the

atmosphere with a discharge velocity of at least 8 m/s.

4. The entire system/piping should always be thorough-

ly inspected for leaks. Leaks must be sealed. The sy-

stem must not be used for the following 24 hours.

5. It is important to install the product so that it is not

possible for rainwater to penetrate. An example of a

well-functioning installation is shown in this drawing.

Penetrating rainwater can cause the side channel blow-

er to jam and be destroyed.

6. The connection of the electrical components of the

HVU Lite should only be carried out by an authorized

electrician.

7. For connection options, see separate panel documen-

tation (located in the panel).

Connection of compressed air:

8. Connect clean and dry compressed air. A pressure

regulator must be installed. We recommend to install

a water separator just before the HVU Lite.

5.2.2 Installation of additional equipment

Mounting of a repair switch

The above principle drawing applies to both HVU and

HVU Lite.

The repair switch must be connected to comply with the

EN 60 204-1 standard, where a manual switch must be

connected. The switch will typically be placed 2 - 3 me-

ters from the unit and must be clearly visible.

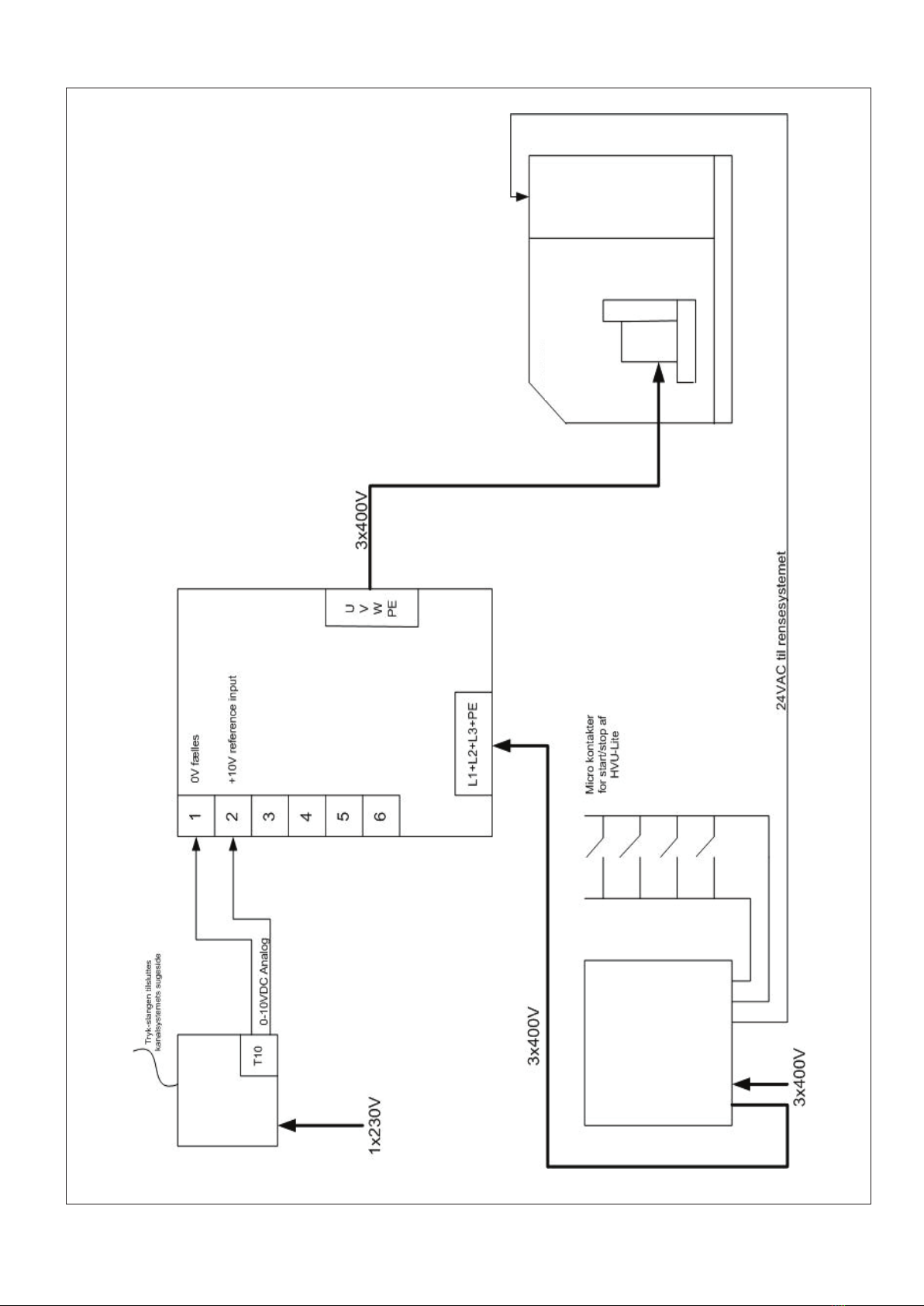

Mounting of frequency inverter

We have the possibility to deliver with frequency inverter

and/or pressure control. See manual for pressure con-

trol.

For setting options for external frequency inverter - refer

to the manual of the frequency inverter.

Aftappehane

Luft ind

30 mm isolering

af hensyn til

kondens

Air in

Air out

Drain tap

30 mm insulation

for condensation

Instruktionsmanual Højvakuumunit – HVU-Lite 30 & 55

29-01-2007 ver. 1.0 www.geovent.com Side 3/6

3. For at sikre fri opblanding, bør afkastet føres

to meter over tagryg mod atmosfæren med

en afkast-hastighed på minimum 8 m/s.

4. Hele anlægget/rørføringen bør altid efterses

grundigt for utætheder. Utætheder seales.

Anlægget må ikke anvendes i de

efterfølgende 24 timer.

Tilslutning af ventilator til El-nettet:

5. Tilslutningen af HVU-Lite’ens elektriske

komponenter bør kun udføres af autoriseret

EL-installatør.

6. For tilslutningsmuligheder se diagram side 6.

2.1 Montering af ekstraudstyr

Montering af reparationsafbryder

Her er afbilledet en HVU, men samme gælder for HVU-Lite.

Reparationsafbryder skal tilsluttes for at leve op til

EN 60 204-1 standarden, hvor der skal tilsluttes

en manuel afbryder. Afbryderen vil typisk placeres

2 – 3 meter fra unitten og skal være tydelig synlig.

Flowguard

I Danmark skal alle udsugningsanlæg forsynes

med kontrolanordning til kontrol af korrekt sug iht.

Arbejdstilsynet. Se separat vejledning herom.

Montering af frekvensomformer

For tilslutningsmuligheder for frekvensomformer

se diagram på side 6

For indstillingsmuligheder for ekstern frekvens-

omformer se separat medfølgende manual

(Digidrive).

For detaljere diagram se bilag - bagerste sidst.

2.2 Testkørsel - finjustering

Efter endt installation tjek da, om der er rystelser

eller lydgener ved HVU-Lite’en.

Tjek at hele anlægget er fuldstændigt tæt. Ved

pibelyde, bør utætheden lokaliseres og tætnes

med fugemasse.

Det kan anbefales at tjekke om HVU-Lite’en

levere den luftmængde som anlægget er

dimensioneret til. Mål derfor luftmængden og sørg

for at den ikke overstiger motorens ampere-tal.

3.0 Anvendelse - Brugerinstruktion

HVU-Lite må ikke køre i længere perioder (mere

end 45 min) uden åbne udtag i kanalsystemet, da

pumpen ellers vil overophede og gå i stykker.

Anvend evt. den indbyggede start/stop funktion.

Control panel

3x400V + PE

Repair switch

Pressostat

1x230V

Adjustment of Flowguard

1” Shut-off valve

8mPa (8Bar) clean and

dry compressed air

Flexible connection 1”

compressed air hose

Filter regulator