7

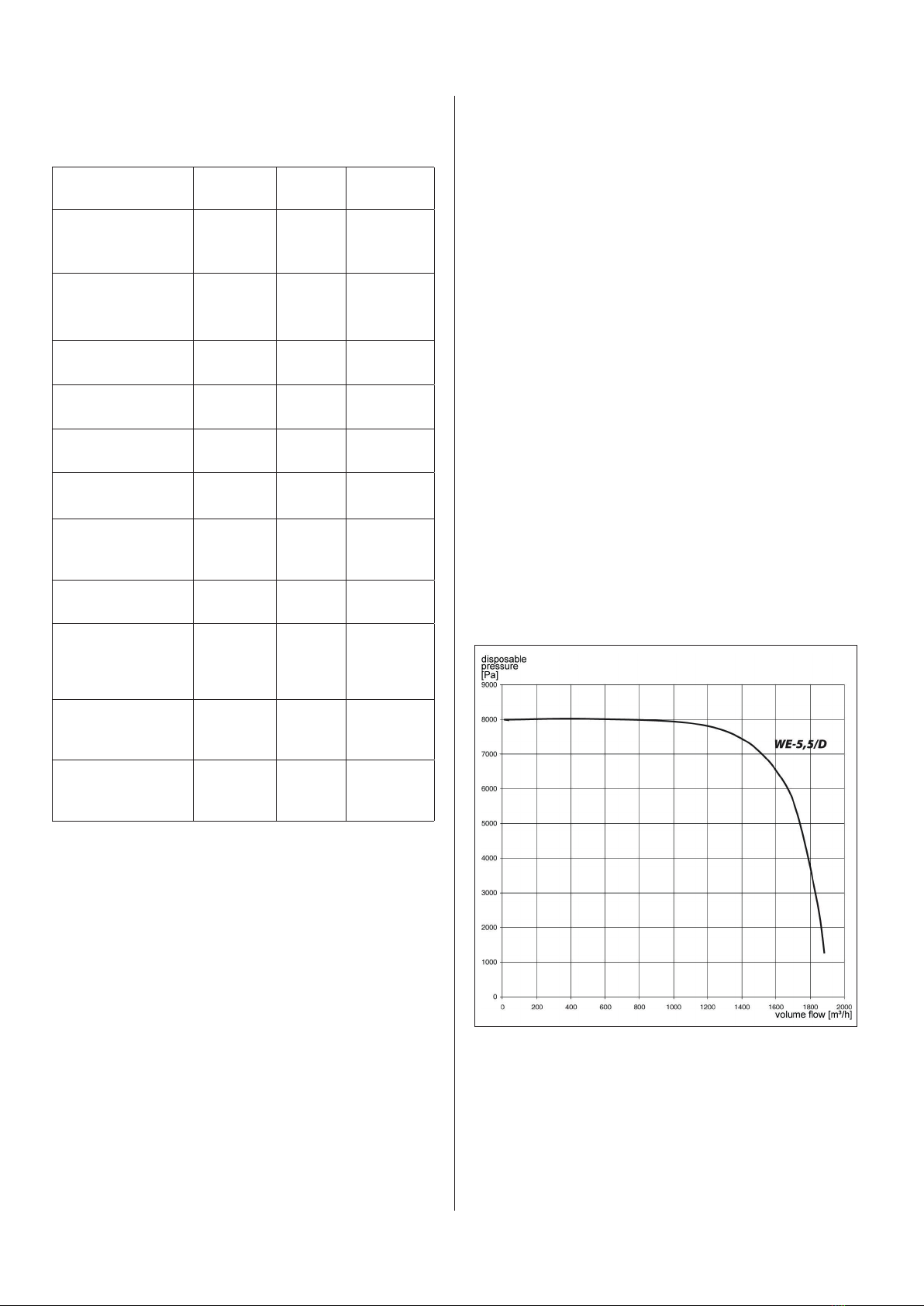

A silencer (900/1200 mm – Ø200/250) and a spiro for

the outdoors are recommended on the return (Ø200/250

mm recommended). Electrical work must be carried out

by certied personnel in accordance with current regu-

lations.

See also chapter 5.

Before starting, check the following:

- Correct supply voltage and grounding

- Correct connection of phases on the motor, correctly

set motor protection, correctly secured main course

- Check the physical direction of rotation of the fan. If the

impeller has the wrong direction of rotation, the suction

is poor.

- Check motor protection settings, are these set slightly

above the rated current on motors?

- Check that all microswitches are correctly connected

on the panel

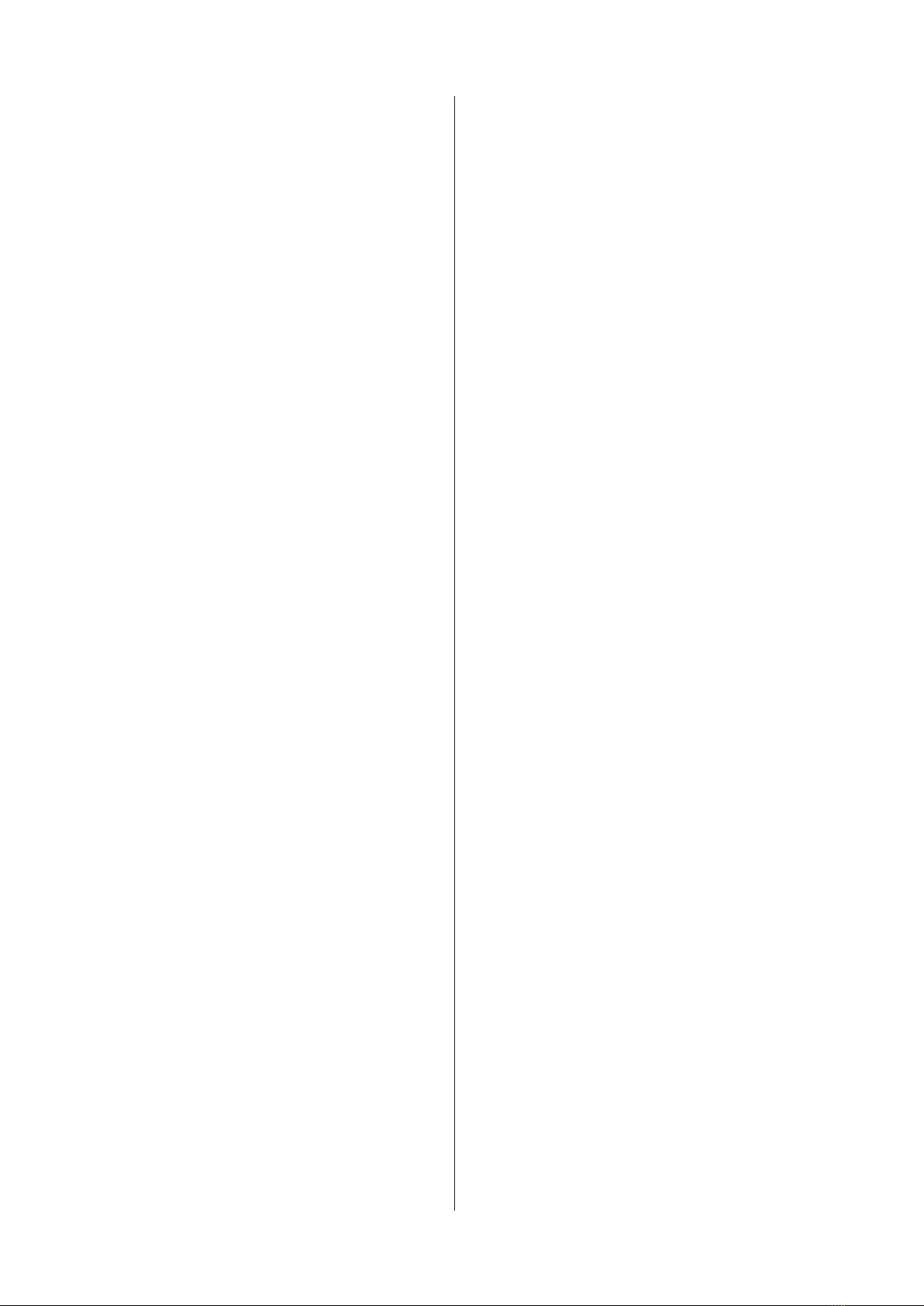

- Correct attachment of the bag lter and the waste bag

- Doors closed and tightened (“false” air can cause the

bag to be sucked up and sound the alarm)

- KCapacitive sensor must be adjusted correctly. The ad-

justment screw for sensitivity is under the black cover

screw.

- Test the device by setting the black switch to the

“Local” position

- Filter cleaner takes approx. 20 seconds after stopping

- Put the black switch in “Remote” and test start and stop

from dampers/valves/micro switches

7 Use, application and alarms

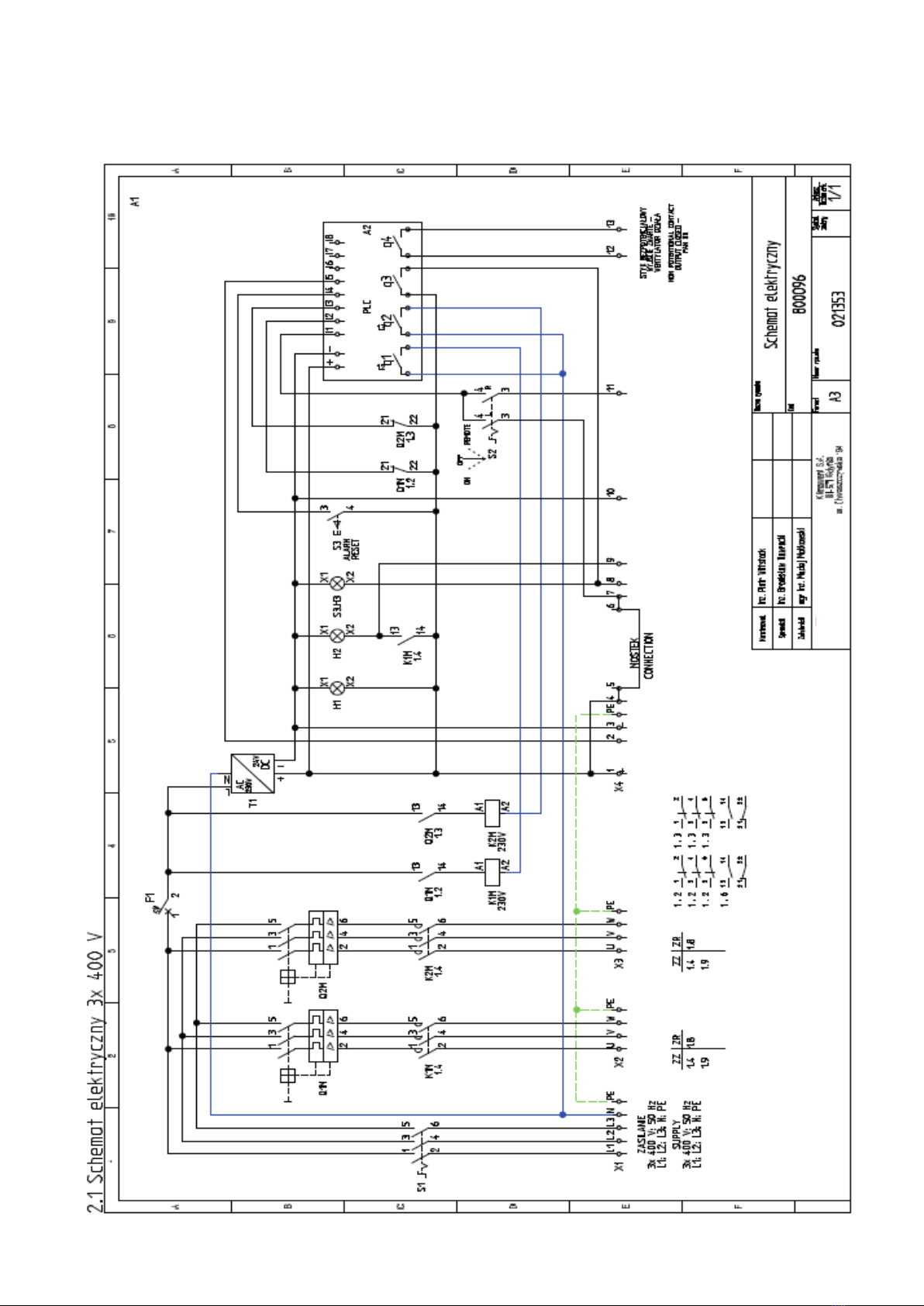

Connection of the main switch, the unit in stand-by

Turn the red switch to the “ON” position

- The yellow lamp (-H1) lights up.

Start of fan/extraction - test run

Turn the black control switch to the “Local” position to

start the test. The fan starts, indicated by a lit white sig-

nal lamp. Then set the black switch to the “Remote” po-

sition.

Operation/remote control of the unit

For automatic operation of the unit, set the red switch

to “On” and the black switch to “Remote”. The unit must

now be started and stopped when sliding dampers and

ap valves are used. Micro switches must be connected.

Disconnection of Aggregate:

To stop the unit, set the red switch (-S2) to position

“OFF” and then

turn the switch (-S1) to the “OFF” position.

Full-bag alarm (steady red light):

When the waste bag is full, or the capacitive sensor de-

tects something in front (for example a waste bag), the

red lamp (- H3) “ALARM” lights up. The fan is stopped,

the bag must be emptied or the obstruction must be re-

moved, the alarm can be reset and the system starts

again.

For emptying the bag; Open the bottom door, pull out the

trolley with the waste bag to change the bag.

Clean any capacitive sensor.

Replace the waste bag with a new one, place the trolley

into the unit, lift the bag into place with the weight arms

of the trolley, close the door properly.

NB! Clean properly if there are chips around the door/

gasket. False air will cause the bag to be sucked up and

trigger the alarm again!

Under normal conditions, the shaking motor starts and

shakes the lter for approx. 20 seconds each time the

unit is stopped. The shaking removes ne dust from the

bag lter and gives a longer lter life.

Error - motor protection tripped (ashing red light)

In the event of a fault on the motor protection switch

(-Q1) or (-Q2), the lamp (-H3) “ALARM” ashes. The fan

then switches o automatically. Check the switch and

electrical connections, then start the fan by pressing the

(-S3) “RESET” button.

Examples of incorrect use and incorrect operating

areas:

a. Dust and gases beyond temperatures -20°C to 40°C.

b. Extraction of explosive dust and gases

c. Extraction of aggressive, damp or sticky media

d. Extraction of gas, smoke or dust below 10 microns

e. Extraction from hot processes (metal grinding)

Possible consequences of incorrect use:

- Clogged lters

- Damage to bearings and axles

- Corrosion damage

- Imbalance on fan, impeller

- Vibrations and damage to the shaker motor

- Deformations and fatigue fractures

- Damage due to friction

- Sparks and ignition sources can cause ignition

8 Problem solving

Always switch o the power before working on the unit,

motor, electrics, impeller etc.

Extraction disappears while the fan is running.

Clogging in the suction channel, at a branch etc. Must be

opened and cleaned

Fan stops

Check motor, impeller, supply, fuse. Contact an elec-

trician. Regarding fan motor must be checked by the

manufacturer/specialist. Check any alarms (full bag or

engine protection)

Vibrations

Check the impeller for dirt or damage. Check engine for

bearing noise.