54

3. General Description of Use

Tool Changing

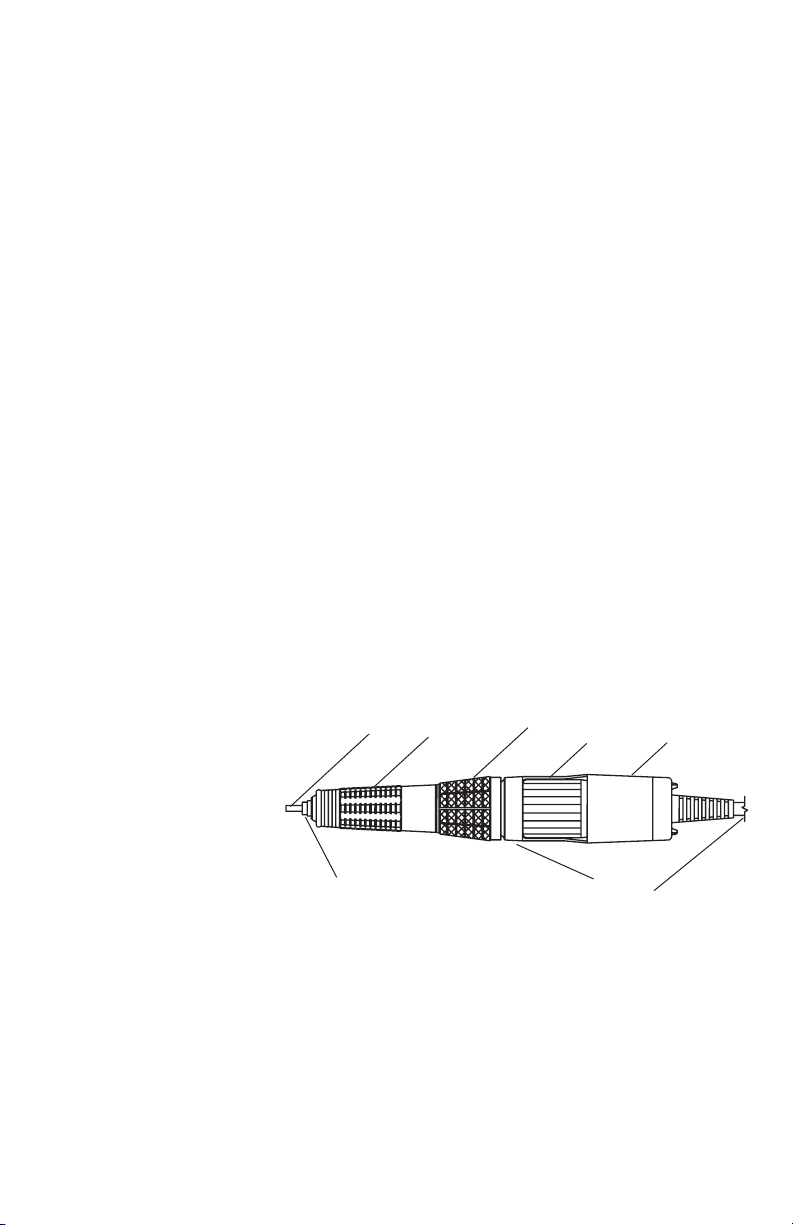

The Gesswein Power Hand 2X Rotary Handpiece

uses a quick-tool-release mechanism that allows

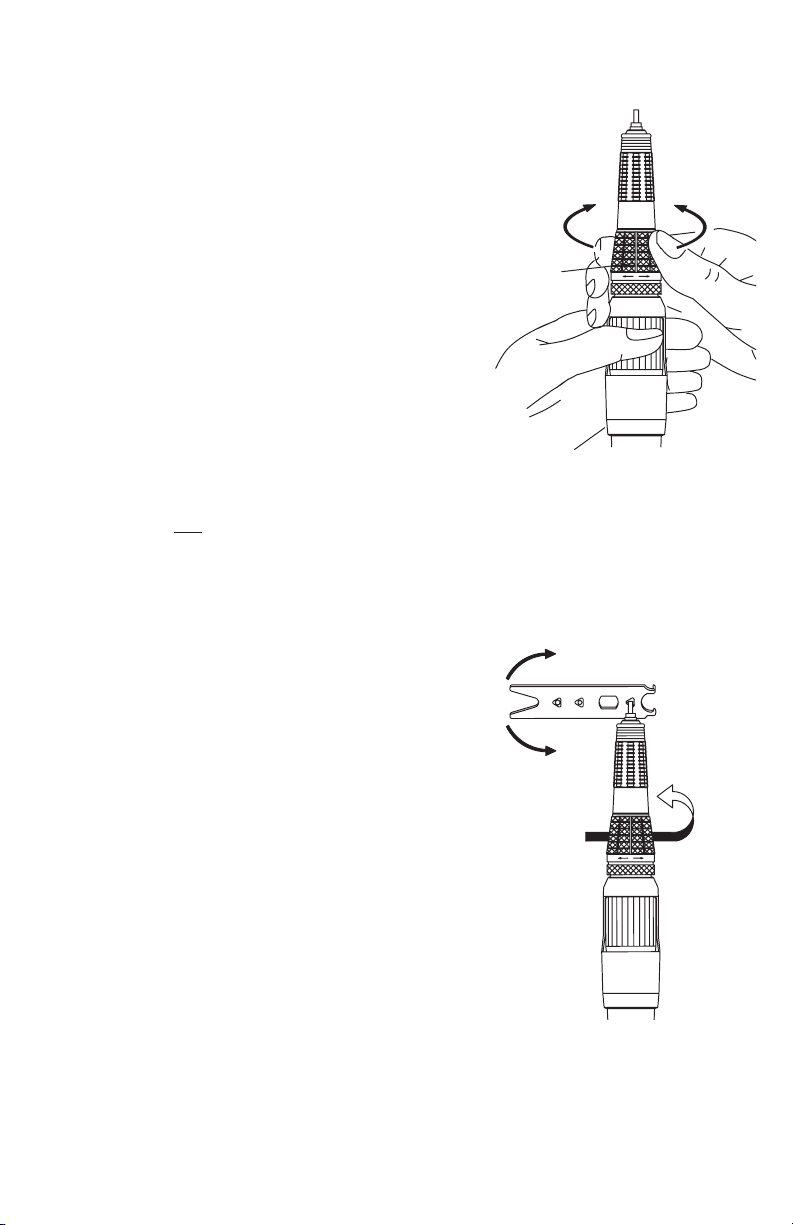

for rapid tool changes. To operate, turn the Collet

Release Ring toward the arrow pointing to the

“R” or release position (see fig. 2). When in full

“R” position, the Collet Release Ring will make

a click sound; the collet is then fully open and

ready to accept a tool.

To secure the tool, rotate the Collet Release

Ring toward the “S” or secure position. Again, a

click sound will be heard, indicating the collet is

fully closed and the tool is secure.

When changing tools, be sure that the hand-

piece motor is not running. If you attempt a tool

change under this condition, the motor will be

stalled and damage will occur.

Collet Removal

The Gesswein Power Hand 2X Rotary

Handpiece can be fitted with three different size

collets. Standard sizes are 3⁄32" (2.35mm) and 1⁄8"

(3.2mm). Bright Cutting Package supplied with a

3.0mm collet.

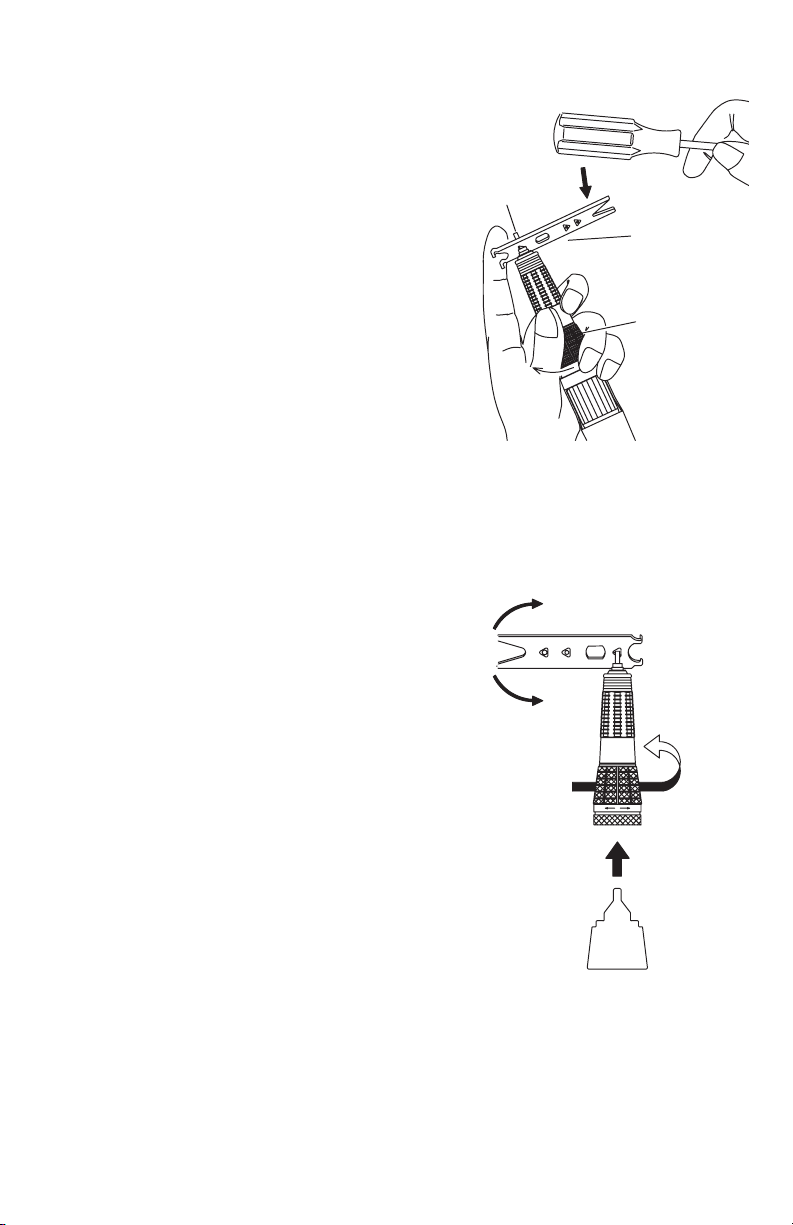

To change collets, rotate the Collet Release Ring

to the full “R” position and remove the tool in the

collet. Hold the collet between thumb and fore-

finger and turn in a counterclockwise direction

until the collet is removed. Insert the new collet

and reverse the procedure. It is best to tighten

a replaced collet by hand with the collet wrench

(#510-0180), securing until just tight.

R S

Collet

Wrench

Tighten

R

Loosen

Fig. 3

Collet

Release

Ring

SR

RS

Fig. 2

Blank Bar

R

Collet

Wrench

Collet

Release

Ring

Fig. 3a

If the collet cannot be loosened by hand using

the Collet Wrench, additional torque may be

required. To use the Collet Wrench, place the tri-

angular cutout in the wrench over the collet (see

fig. 3), and turn counterclockwise to loosen and

clockwise to tighten the collet. If more torque

is required, hold the handpiece with the Collet

Wrench secure on the collet, and tap the wrench

with a solid tool (see fig. 3a) in a counterclock-

wise direction. This procedure will loosen the

collet, which can then be removed by hand.

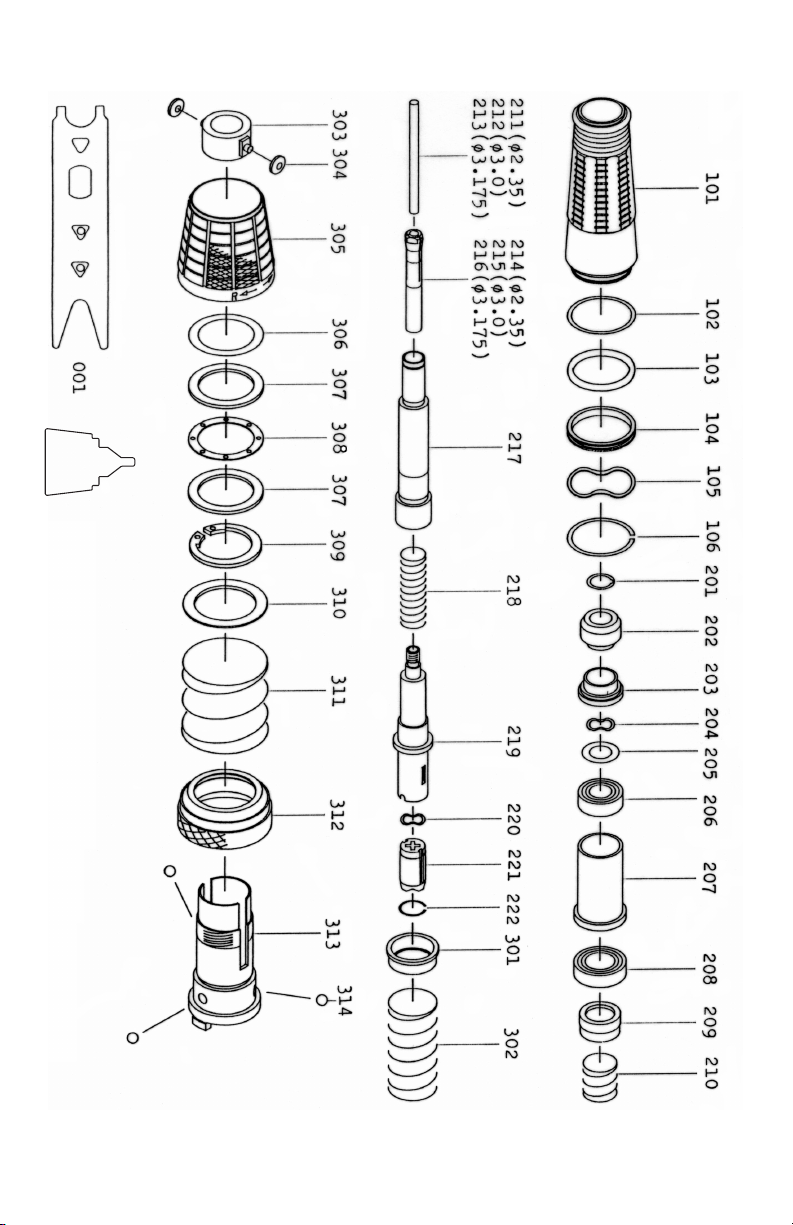

If the handpiece collet is so tight that the above

procedure will not loosen it, then remove the

Head Assembly from the Motor Assembly. This

can be done by grasping the Motor Connecting

Ring (see fig. 1) and pulling upward. Insert the

Chuck Joint Wrench (see Fig. 3b) into the Nylon

Coupler (#510-0151), hold the Head Assembly

and Chuck Joint Wrench securely in one hand,

and with the Collet Wrench in place on the collet,

loosen in a counterclockwise direction (for parts

drawing, refer to page 7.)

After a collet is replaced, be sure that the Collet

Release Ring is rotated to its full “S” position

and that the collet rotates freely when turned by

hand. If the collet does not rotate freely, it is not

fully seated in the Head Assembly, and you must

repeat the removal-replacement procedure.

RS

Chuck

Joint

Wrench

Collet

Wrench

R

Tighten

Loosen

Fig. 3b