2

Contents

Page

Important notes

Usage for the intended purpose...............................................................................................................5

Safety note..............................................................................................................................................5

PED (Pressure Equipment Directive) ........................................................................................................6

ATEX (Hazardous Area) ............................................................................................................................6

Note on the Declaration of Conformity / Manufacturer's Declaration ..............................................6

Explanatory Notes

Scope of supply ......................................................................................................................................7

Description..............................................................................................................................................8

Function ................................................................................................................................................9

Technical Data

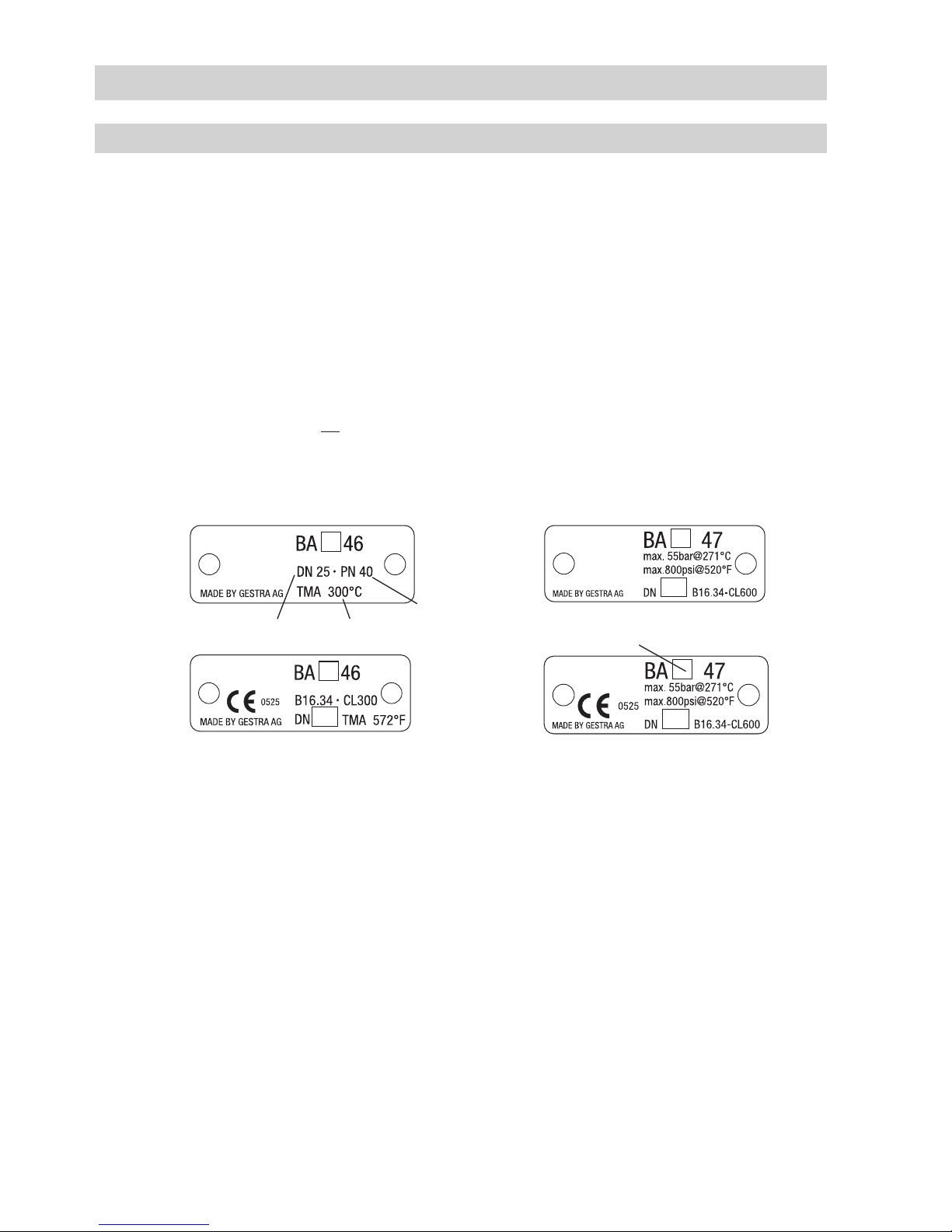

Name plate / marking ...........................................................................................................................10

Dimensions BA 46, BA 47......................................................................................................................11

Dimensions BAE 46..., BAE 47...............................................................................................................12

Dimensions of flanged ends (extract).....................................................................................................13

Dimensions of butt-weld ends (extract) .................................................................................................14

Dimensions of socket-weld ends (extract) .............................................................................................14

Pressure /Temperature Ratings & End Connections ...............................................................................15

Materials...............................................................................................................................................16

Actuator ................................................................................................................................................16

Capacity chart for DN 15 to 32, capacity ranges at a glance..................................................................17

Capacity chart for DN 15 to 32 , capacity range up to 310 kg/h............................................................18

Capacity chart for DN 15 to 32 , capacity range up to 1020 kg/h..........................................................19

Capacity chart for DN 15 to 32 , capacity range up to 2120 kg/h..........................................................20

Capacity chart for DN 40 and 50, capacity ranges at a glance ...............................................................21

Capacity chart for DN 40 and 50, capacity range up to 1340 kg/h ........................................................22

Capacity chart for DN 40 and 50, capacity range up to 4500 kg/h ........................................................23

Capacity chart for DN 40 and 50, capacity range up to 6300 kg/h ........................................................24

Design

BA 46, BA 47.........................................................................................................................................25

BAE 46..., BAE 47..................................................................................................................................26

Key .......................................................................................................................................................27