2

Contents

Usage for the intended purpose ..............................................................................................................4

Safety note .............................................................................................................................................4

Danger ...................................................................................................................................................4

Attention.................................................................................................................................................4

LV (Low Voltage) Directive and EMC (Electromagnetic Compatibility) .......................................................4

ATEX (Atmosphère Explosible).................................................................................................................4

Note on the Declaration of Conformity / Declaration by the Manufacturer ..........................................4

Important Notes

Page

Explanatory Notes

Scope of supply......................................................................................................................................5

Description .............................................................................................................................................5

Function .................................................................................................................................................5

Design....................................................................................................................................................5

NRGS 11-1, NRGS 16-1, NRGS 16-1S .................................................................................................13

NRGS 11-1, NRGS 16-1 .......................................................................................................................13

NRGS 16-1S ........................................................................................................................................13

Table Functions.....................................................................................................................................13

Attention...............................................................................................................................................14

Note .....................................................................................................................................................14

Tools.....................................................................................................................................................14

Examples of installation ........................................................................................................................15

Key.......................................................................................................................................................16

Installation

Technical Data

NRGS 11-1, NRGS 16-1, NRGS 16-1S ............................................................................................... 6, 7

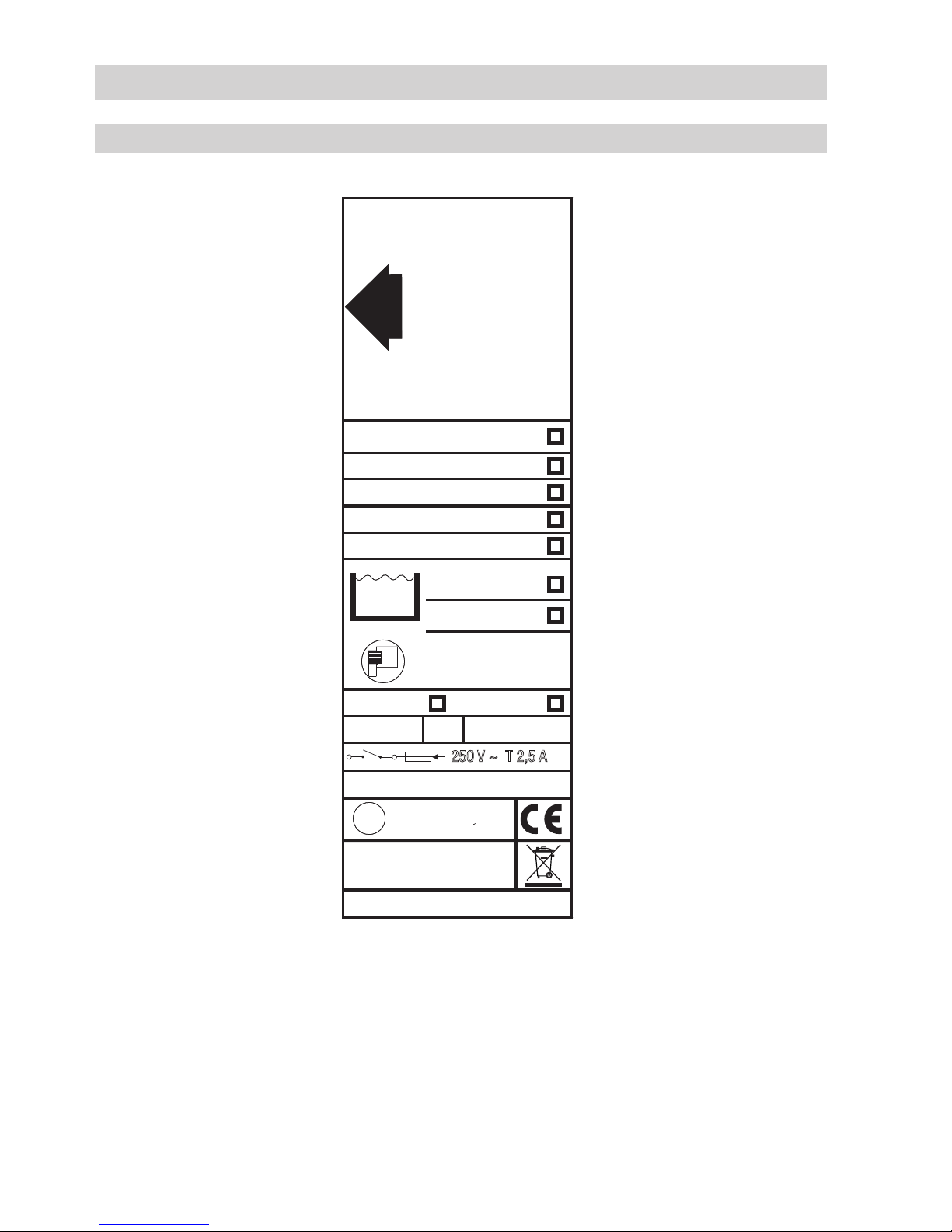

Name plate / marking .............................................................................................................................8

Dimensions.............................................................................................................................................9

Key.......................................................................................................................................................12

Functional Elements

NRGS 11-1, NRGS 16-1, NRGS 16-1S .................................................................................................11

Key.......................................................................................................................................................12

Design

NRGS 11-1, NRGS 16-1, NRGS 16-1S .................................................................................................10

Key.......................................................................................................................................................12