3

1 Safety guidelines to operate the dolly

Adherence to the instruction manual:

The set-up instructions must be read and understood before set-up or operation.

The dolly may only be assembled in accordance with the manufacturer’s instruction manual. The

manufacturer’s technical specifications and limits (maximum rated loads etc.) must be adhered to at all

times and in no way exceeded.

Warranty:

The manufacturer accepts no liability for damages or injuries for incidents or accidents occurring due

to negligence by the crane operator or misuse of the crane or disregarding the instruction manual.

Assembling and operation of the dolly:

The Dolly may only be set-up or operated by trained and experienced personnel. To assemble and

operate the dolly at least 1 trained person is required. To avoid misuse by untrained personnel, the

dolly should be dismantled / switched off and secured when not in use or under supervision.

The dolly may not be set-up or operated under the influence of alcohol, drugs or any other intoxicating

substances. The respective protective clothing e.g. gloves, should be worn.

Structural stability requirements for use of the dolly system:

Before assembling or using the dolly ensure that the ground surface is stable and cannot give way.

The ground surface must be stable enough to support at least 1000 kg/m2 = 2200 lbs/ sq yard.

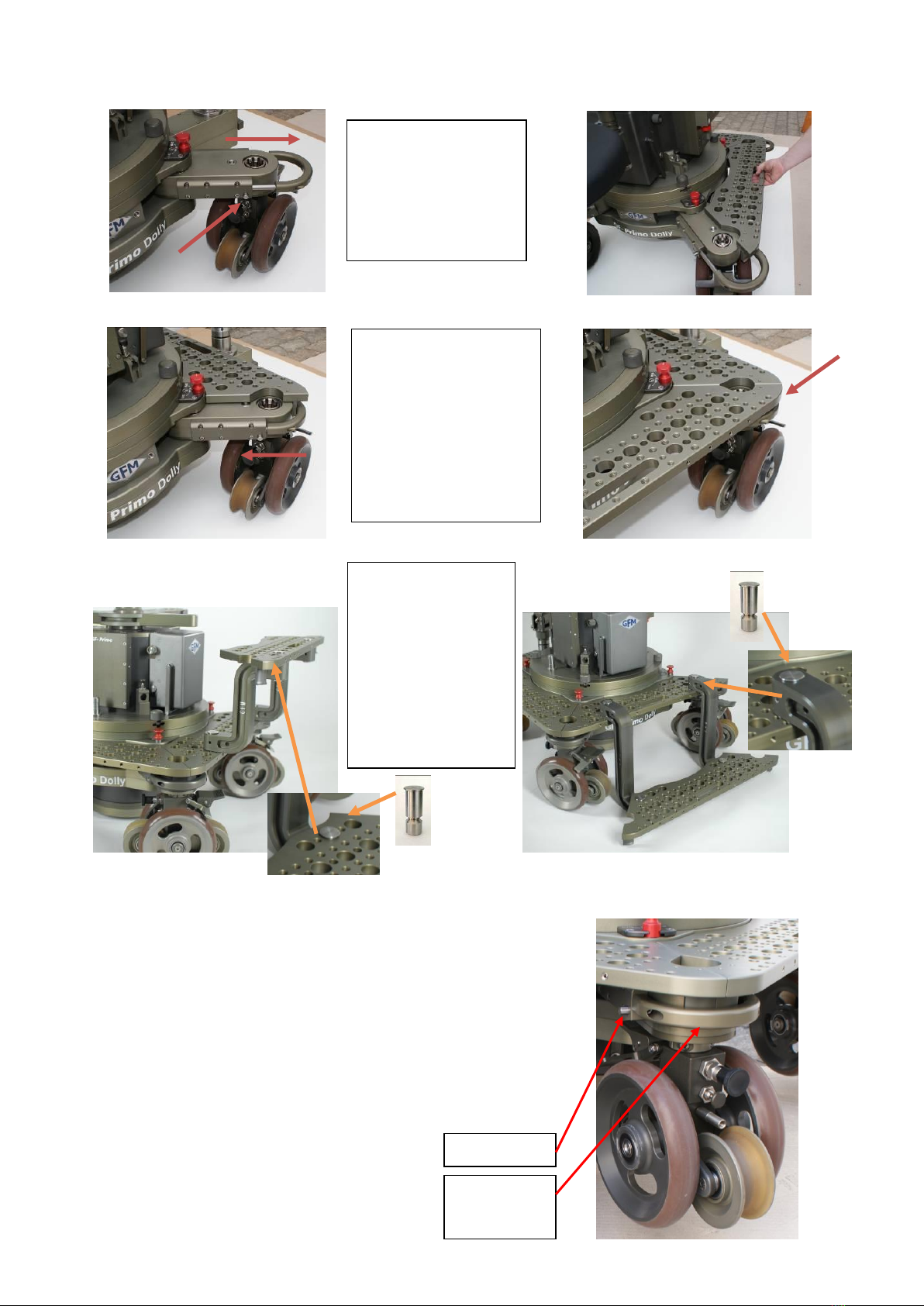

Dolly operation with the GF-Primo Jib is only allowed with solid wheels and use with pneumatic

wheels is not allowed. Before and while using the dolly wheels should be inspected.

Intended use of the Dolly system and use of the Dolly system with Jib Arm:

The Dolly is a mobile personnel and camera support system for use on sets and studios with stable,

even and level ground / floors. Also for use on GF-Track.

Standard dolly operation consists of lifting 1 to 2 persons and camera or lifting the camera only,

without personnel on board, electromechanical column for lifting 1 to 2 persons and camera or lifting

the camera only, without personnel on board.

In Jib mode a pan and tilt arm is mounted for lifting 1 to 2 persons and camera or lifting the camera

only, without personnel on board

In accordance to the safety guidelines the dolly/jib is only allowed to be used on solid, level and stable

ground with solid wheels, not pneumatic wheels.

The dolly/jib movement on the ground, rotation of the column is managed by 1 to 2 experienced,

trained and authorised personnel from the hand grips and /or the provided steering handles.

Panning movement of the turnstile mount / column can also be made by the personnel sitting on the

column/dolly when seated on the provided seats.

Vertical lift of the column is controlled via wireless or cable control operated by an experienced, trained

and authorised person.

Operation of the dolly/jib is only allowed within the limits and guidelines mentioned in this instruction

manual.

The dolly must be operated on level, stable surfaces at all times or on dolly track. Whether operating

or moving the dolly on track or on a solid ground surface it is essential that the track or surface is

completely level, stable and free from obstructions.

When operating the dolly on track, ensure that the track is level, properly laid, constructed and

supported. The correct underlay must be used to ensure that the track and underlay are secured

against moving, slipping and collapse. Ensure that the underlay meets the specified support and

stability requirements. Only GFM Track or comparable track systems with a payload capacity of

1200kg / 2640lbs and a maximum track runner distance of 640mm / 25inches (measured inside edge

to inside edge) may be used.

Extreme caution if tracking on curved track (not faster than a slow walking pace)!