5

Table 1

RECOMMENDED MINIMUM AWG SIZE FOR

EXTENSION CORDS FOR BATTERY CHARGERS

AC Input Rating Amperes AWG Size of Cord

Equal to or but less than Length of Cord, Feet (Meter)

greater than 2.5(7.5) 50(15) 100(30) 150(45)

0 2 18 18 18 16

2 3 18 18 16 14

3 4 18 18 16 14

If the input rating of a battery charger is given in

watts rather than in amperes, the corresponding

ampere rating is to be determined by dividing the

wattage rating by the voltage rating-for example:

1,200 watts/120volt=10 Amperes

9. Do not operate battery charger with damaged

cord or plug ,should replace them immediately.

10. Do not operate battery charger if it has received

a sharp blow, been dropped, or otherwise damaged

in any way; take it to a qualified serviceman.

11. Do not disassemble battery charger; take it to a

qualified serviceman when service or repair is

required.

Incorrect reassembly may result in a risk of

electric shock or fire.

12. To reduce risk of electric shock, unplug charger

from receptacle before attempting any maintenance

or cleaning. Removing the battery will not reduce

this risk.

13. Please read this Manual before using the battery

charger.

IMPORTANT SAFETY INSTRUCTIONS FOR USE

OF THE BATTERY AND BATTERY CHARGER

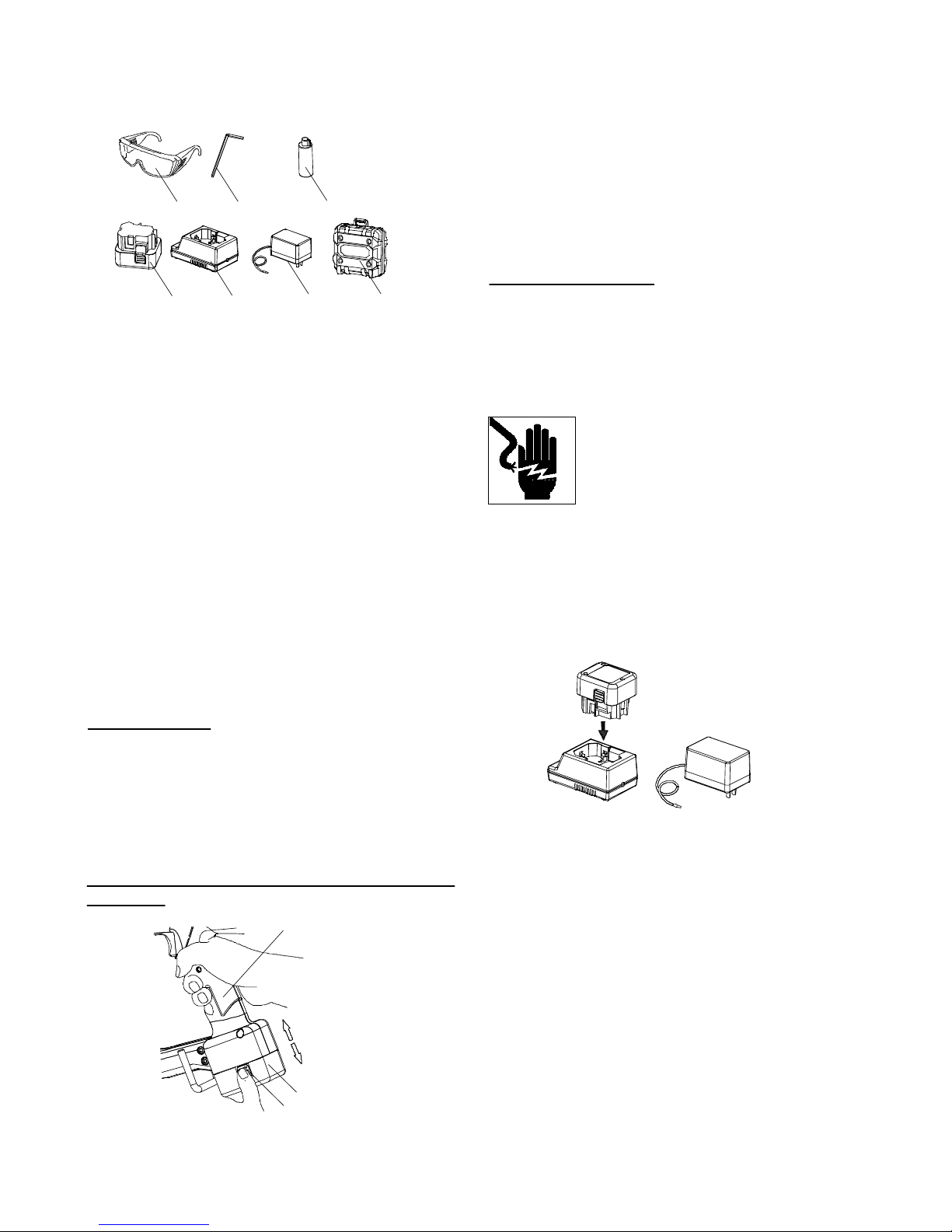

You must charge the battery before you use the

Nailer. Before using the model 503.1.16.001.01

battery charger, be sure to read all instructions and

cautionary statements on the battery and in this

manual.

R EM EM BER : ONLY US E *)6 B AT TE RY

TYPE503.1.10.001.01.

OTHER TYPES OF BATTERIES MAY BURST

AND CAUSE INJURY!

Follow these instructions to avoid the risk of injury:

WARNING

Improper use of the battery or battery charger

can lead to serious injury. To avoid these injuries:

1. DO NOT disassemble the battery.

2. DO NOT incinerate the battery, even if it is

damaged or is completely worn out.

The battery can explode in a fire.

3. DO NOT short-circuit the battery.

4. DO NOT insert any objects into the battery

charger's air vents. Electric shock or

damage to the battery charger may result.

5. DO NOT charge outdoors. Keep the battery away

from direct sunlight and use only where

there is low humidity and good ventilation.

6. DO NOT charge when the temperature is below

50°F (10°C) or above 104°F (40°C).

7. DO NOT connect two battery chargers together.

8. DO NOT insert foreign objects into the hole for

the battery or the battery charger.

9. DO NOT use a booster transformer when charging.

10.DO NOT use an engine generator or DC power

to charge.

11. DO NOT store the battery or battery charger in

places where the temperature may

reach or exceed 104°F (40°C).

12. MUST TO DO operate charger on standard

household electrical power (120 volts).

Using the charger on any other voltage

may overheat and damage the charger.

13. MUST TO DO wait at least 15 minutes between

charges to avoid overheating the

charger.

14. MUST TO DO disconnect the power cord from

its receptacle and cut off the charger

power when the charger is not in use.

DISPOSAL OF THE EXHAUSTED BATTERY

WARNING

Do not dispose of the exhausted battery. The

battery must explode if it is incinerated. The

product that you have purchased contains a

rechargeable battery. The battery is recyclable.

At the end of it's useful life, under various state

and local laws, it may be illegal to dispose of

this battery into the municipal waste stream.

Check with your local solid waste officials for

details in your area for recycling options or proper

disposal.

EMPLOYER'S RESPONSIBILITIES

1. Ensure that this MANUAL is available to operators

and personnel performing maintenance.

2. Ensure that Nailers are used only when operators

and others in work area are wearing EYE PROTECTOR.

3. Enforce the use of EYE PROTECTOR by operators

and others in work area.

4. Keep Nailers in safe working order.

5. Maintain Nailers properly.

6. Ensure that Nailers which require repair are not

further used before repair.

SAV E TH ESE MA NU AL A ND MAK E THEM

A VA ILABLE TO OTHER USERS AND OWNERS

OF THIS TOOL!