EN

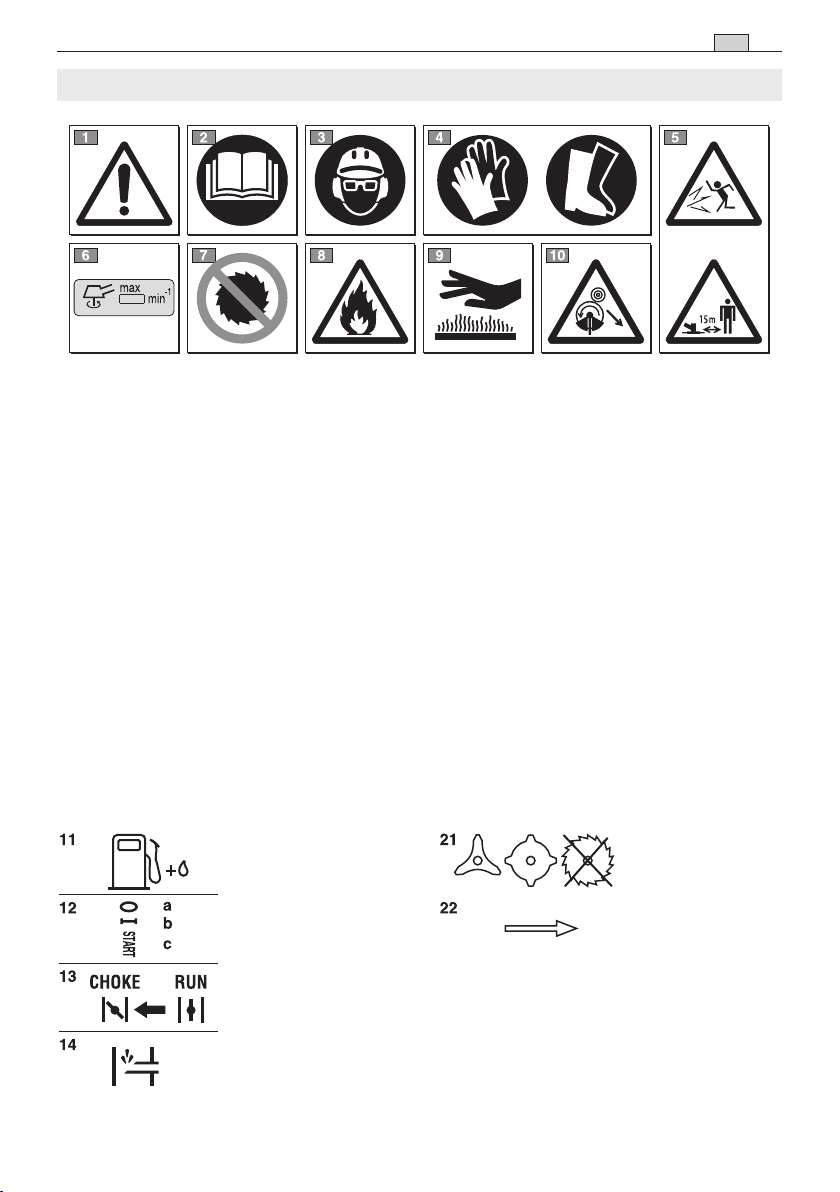

A) TRAINING

1) Read the instructions carefully. Become a c-

quainted with the controls and the proper use of

the machine. Learn how to stop the engine qui ckly.

2) Only use the machine for the purpose for

which it was designed, namely

– cutting grass and non-woody vegetation,

u sing a nylon line (e.g. around the edges of lawns,

owerbeds, walls, fences and small gras sy areas

to tidy up the cutting done using a mower);

– cutting tall grass, dry branches, twigs and

woody shrubs of up to 2 cm diameter, with the

help of metal or plastic blades.

Any other use may be dangerous and damage the

machine.

Examples of improper use may include, but are not

limited to:

– use the machine for sweeping;

– trimming hedges or other jobs in which the cutting

device is not used on ground level;

– pruning trees;

– using the machine with the cutting device above

the operator’s belt level;

– using the machine for cutting non-plant mate rial;

– use of the machine by more than one person.

3) Never allow children or persons unfamiliar with

these instructions to use the machine. Local re-

gulations can restrict the age of the user.

4) The machine must never be used by more than

one person.

5) Never use the machine:

– when people, especially children or pets are in

the vicinity;

– if the user is tired or unwell, or has taken medi-

cine, drugs, alcohol or any substances which may

slow his reexes and compromise his judgement;

– if the user is not capable of holding the machine

rmly with two hands and/or remaining standing

on the ground whilst working.

6) Keep in mind that the operator or user is re spon-

sible for accidents or hazards occurring to other

people or their property.

B) PREPARATION

1) Always wear adequate clothing which does not

hamper movements when using the machine.

– Always wear slim-tting protective clothing, tted

with shear-proof protection devices.

– Always wear a helmet, protective gloves, eye-

gog gles, a half-mask respirator and safety anti-

shear boots with non-slip soles.

– Always wear ear and hearing protection de vi ces.

– Never wear scarves, shirts, necklaces, or any

hanging or apping accessory that could catch

in the machine or in any objects or materials in

the work area.

– Tie your hair back if it is long.

2) WARNING: DANGER! Petrol is highly am-

mable:

– keep the fuel in containers which have been spe-

cically manufactured and homologated for such

use;

– never smoke when handling fuel;

– slowly open the fuel tank to allow the pressure

inside to decrease gradually;

– top up the tank with fuel in the open air, using a

funnel;

– add fuel before starting the engine. Never re mo ve

the fuel tank cap or add fuel while the en gine is

running or when the engine is hot;

– if you have spilt some fuel, do not attempt to start

the engine but move the machine away from the

area of spillage and avoid creating any source

of ignition until the fuel has evaporated and fuel

vapours have dissipated;

– immediately clean up all traces of fuel spilt on the

machine or on the ground;

– never start the machine in the same place you

re lled it with fuel;

– make sure your clothing does not come into con-

tact with the fuel, on the contrary, change your

clothes before starting the engine;

– always put the tank and fuel container caps back

on and tighten well.

3) Replace faulty or damaged silencers.

4) Before using the machine, check its general

condition and in particular:

– the throttle trigger and the safety lever must mo ve

freely, they must not need forcing and should re-

turn automatically and rapidly back to the neutral

position;

– the throttle trigger must remain locked until the

safety lever is pressed;

– the engine stop switch must easily move from one

position to the other;

– the electric cables and in particular the spark plug

cable must be in perfect condition to avoid the

generation of any sparks, and the cap must be

correctly tted on the spark plug;

– the machine handgrips and protection devices

must be clean and dry and well fastened to the

machine;

– the cutting devices and guards must be un da-

ma ged.

5) Check the correct position of the handgrips and

the connection point of the webbing, and the proper

balance of the machine.

6) Before starting work make sure that the guards

are suitable for the cutting tool being used and are

tted correctly.

7) Thoroughly inspect the whole work area and

remove anything that could be thrown up by the

ma chine or damage the cutting group or engine

(sto nes, branches, iron wire, bones, etc.).

C) OPERATION

1) Do not start the engine in a conned space

where dangerous carbon monoxide fumes can col-

lect.

4SAFETY REQUIREMENTS

3. SAFETY REQUIREMENTS