H60.0.13.6C-17 Operating Manual GMH 3851 Page 2 of 22

_____________________________________________________ _____________________________________________________________________________

Index

1GENERAL NOTE......................................................................................................................................................3

2SAFETY......................................................................................................................................................................3

2.1 INTENDED USE.......................................................................................................................................................3

2.2 SAFETY SIGNS AND SYMBOLS................................................................................................................................3

2.3 SAFETY INSTRUCTIONS .........................................................................................................................................3

3PRODUCT DESCRIPTION......................................................................................................................................4

3.1 SCOPE OF SUPPLY ..................................................................................................................................................4

3.2 OPERATING AND MAINTENANCE...........................................................................................................................4

3.3 START UP AND READINESS FOR OPERATION..........................................................................................................4

3.4 CONNECTIONS .......................................................................................................................................................5

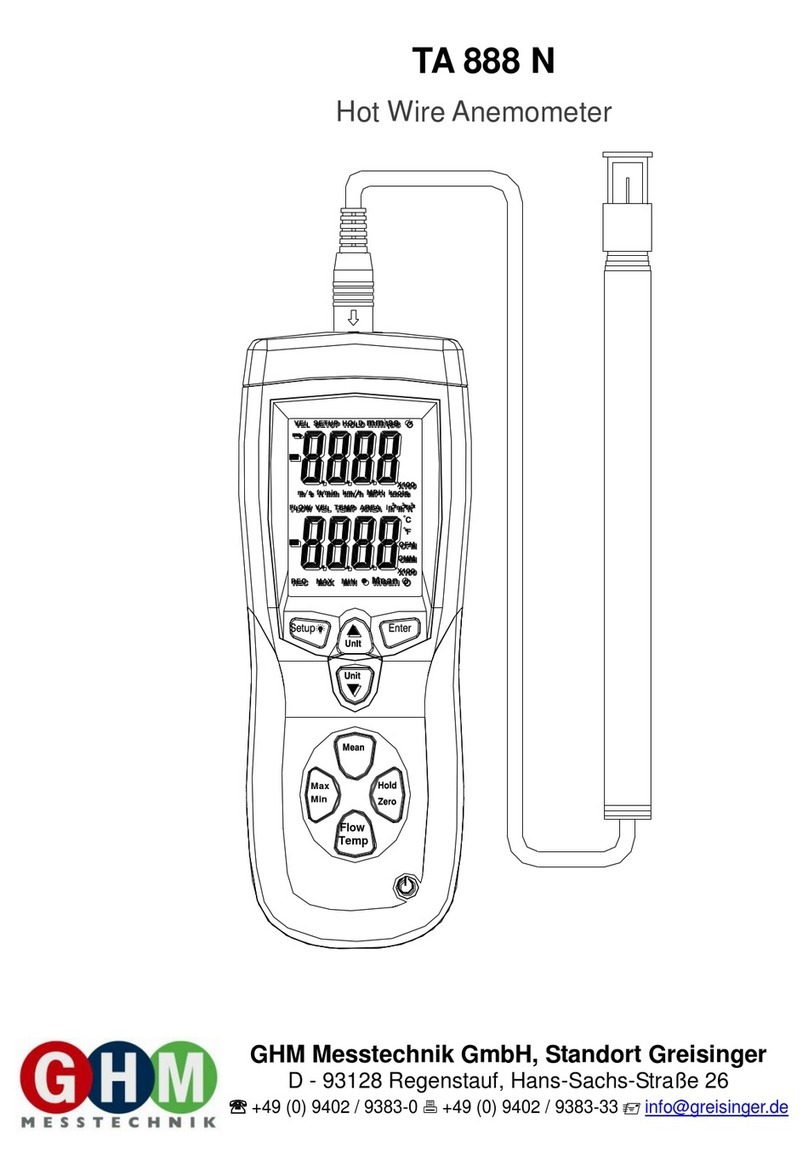

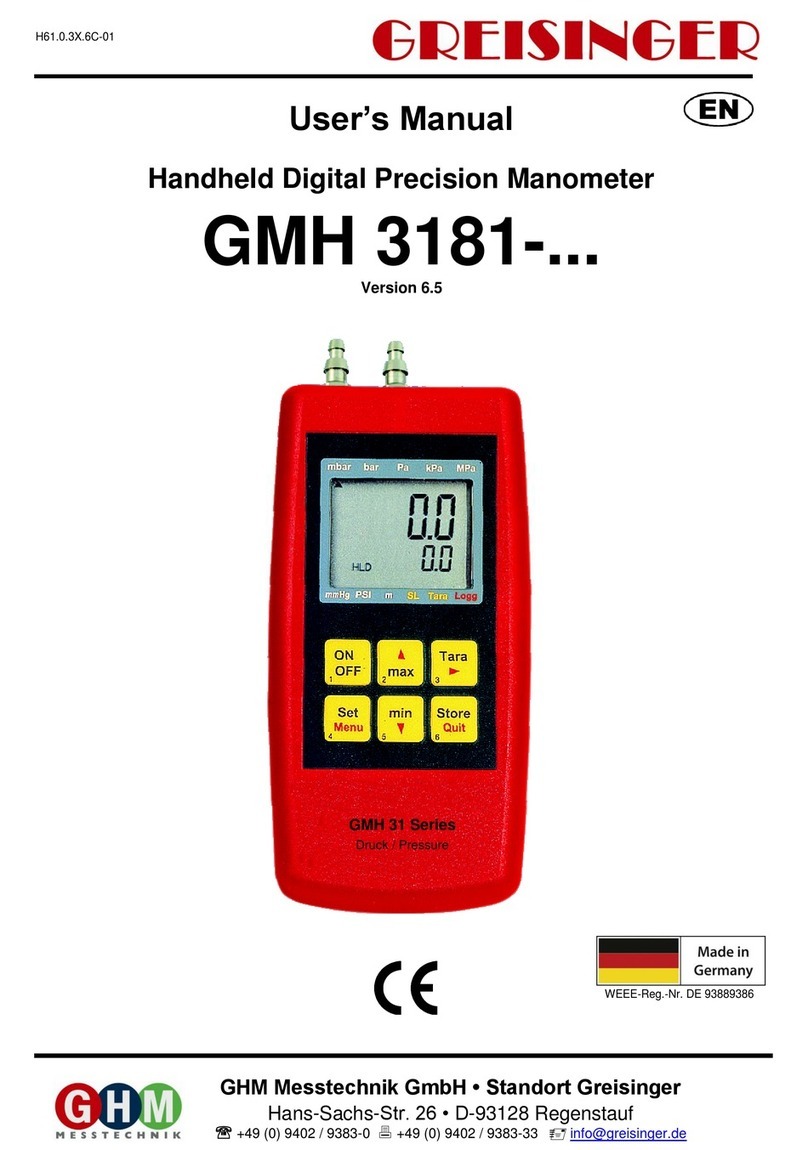

3.5 DISPLAY ELEMENTS ..............................................................................................................................................5

3.6 KEYPAD.................................................................................................................................................................5

4DEVICE CONFIGURATION...................................................................................................................................6

5SOME BASICS OF PRECISION MATERIAL MOISTURE MEASURING......................................................7

5.1 MEASURING METHOD ...........................................................................................................................................7

5.2 MOISTURE CONTENT UAND WET-BASIS MOISTURE CONTENT W........................................................................7

5.3 SPECIAL FEATURES OF THE DEVICE.......................................................................................................................7

5.4 AUTO-HOLD FUNCTION.........................................................................................................................................7

5.5 AUTOMATIC TEMPERATURE-COMPENSATION ('ATC') ...........................................................................................7

5.6 MEASURING IN WOOD:MEASURING WITH TWO MEASURING-NEEDLES.............................................................8

5.7 SPLIT LOG FIREWOOD MEASURING........................................................................................................................8

5.7.1 Presetting.......................................................................................................................................................8

5.7.2 Sampling ........................................................................................................................................................8

5.7.3 Measuring......................................................................................................................................................9

5.8 MEASURING OTHER MATERIALS ........................................................................................................................10

5.8.1 ‘Hard‘ Materials (concrete or similar): Measuring with brush-type probes (GBSL91 or GBSK91)............10

5.8.2 ‘Soft‘ Materials (polystyrene or similar): Measuring with Measuring-rods or -pins (GMS 300/91)...........10

5.8.3 Measuring bulk cargo, bales and other special measures...........................................................................10

5.9 MEASURING OF MATERIALS,HAVING NO CHARACTERISTIC CURVES STORED ....................................................10

6HINTS FOR SPECIAL FUNCTIONS ...................................................................................................................11

6.1 MOISTURE EVALUATION ('WET' -'MEDIUM' -'DRY')...................................................................................11

6.2 PRE-SELECTION OF FAVOURITE MATERIALS ('SORT')..........................................................................................11

6.3 INDIVIDUALLY PROGRAMMABLE CHARACTERISTIC CURVES.............................................................................11

7OPERATION OF LOGGER...................................................................................................................................12

7.1 “FUNC-STOR“: STORING SINGLE MEASUREMENTS.............................................................................................12

7.2 “FUNC-CYCL“: AUTOMATIC RECORDING WITH SELECTABLE LOGGER-CYCLE-TIME .....................................13

8OUTPUT ...................................................................................................................................................................14

8.1 INTERFACE -BASE ADDRESS ('ADR.') .................................................................................................................14

8.2 ANALOGUE OUTPUT –SCALING WITH DAC.0 AND DAC.1................................................................................14

9APPLICATION IN THE GLUED TIMBER CONSTRUCTION AND LAMINATED TIMBER PRODUCTION.............................14

10 FAULT AND SYSTEM MESSAGES.....................................................................................................................15

11 INSPECTION OF THE ACCURACY / ADJUSTMENT SERVICES................................................................15

12 RESHIPMENT AND DISPOSAL...........................................................................................................................15

13 SPECIFICATION....................................................................................................................................................16

14 APPENDIX A: SORTS OF WOOD .......................................................................................................................17

15 APPENDIX B: ADDITIONAL MATERIALS ......................................................................................................22

15.1 MEASURING OF BUILDING MATERIALS ............................................................................................................22

15.2 MEASURING OF AGRICULTURAL BULK CARGO................................................................................................22

15.3 ESTIMATION OF ADDITIONAL MATERIALS .......................................................................................................22