9 JUNE 2021 P a g e | 3 INSTALLATION

3GLOSSARY

Dosing unit- A UV-C lamp assembly that mounts to a vehi le and uses UV-C bulbs to disinfe t the

surfa es inside the vehi le.

grēnlite™- A brand of UV-C produ ts from GHSP that redu e ba teria, spores, viruses, yeasts and molds

inside vehi les.

Upfitter- A spe ialized installer who prepares the vehi le prior to the installation of the UV-C system. An

Upfitter an also install the UV-C system after the vehi le is prepared.

4REQUIREMENTS

The following se tions identify the requirements for the vehi le and the installer. These requirements

must be followed for proper fun tion of the UV-C system.

4.1 E

LECTRICAL

R

EQUIREMENTS

The ele tri al requirements for the ambulan e are listed below. For additional information about

the ele tri al requirements, see the Wiring Diagram in se tion 10.

Battery bank with 9-16 volts dire t urrent (VDC)

Chassis ground from the oa h NEG lug to the hassis

A ess to all door input signals

Cable between the POS and the oa h battery bank must be suffi iently rated. The able

must safely arry 5 amps for ea h dosing unit in the vehi le.

Master power disable relay located between the coach POS lug and the coach battery

bank. The relay should be normally open and will be piloted and closed when the Master

Enable Switch on the control panel is turned to the On position

5PREPARE FOR THE INSTALLATION

5.1

COMPONENTS

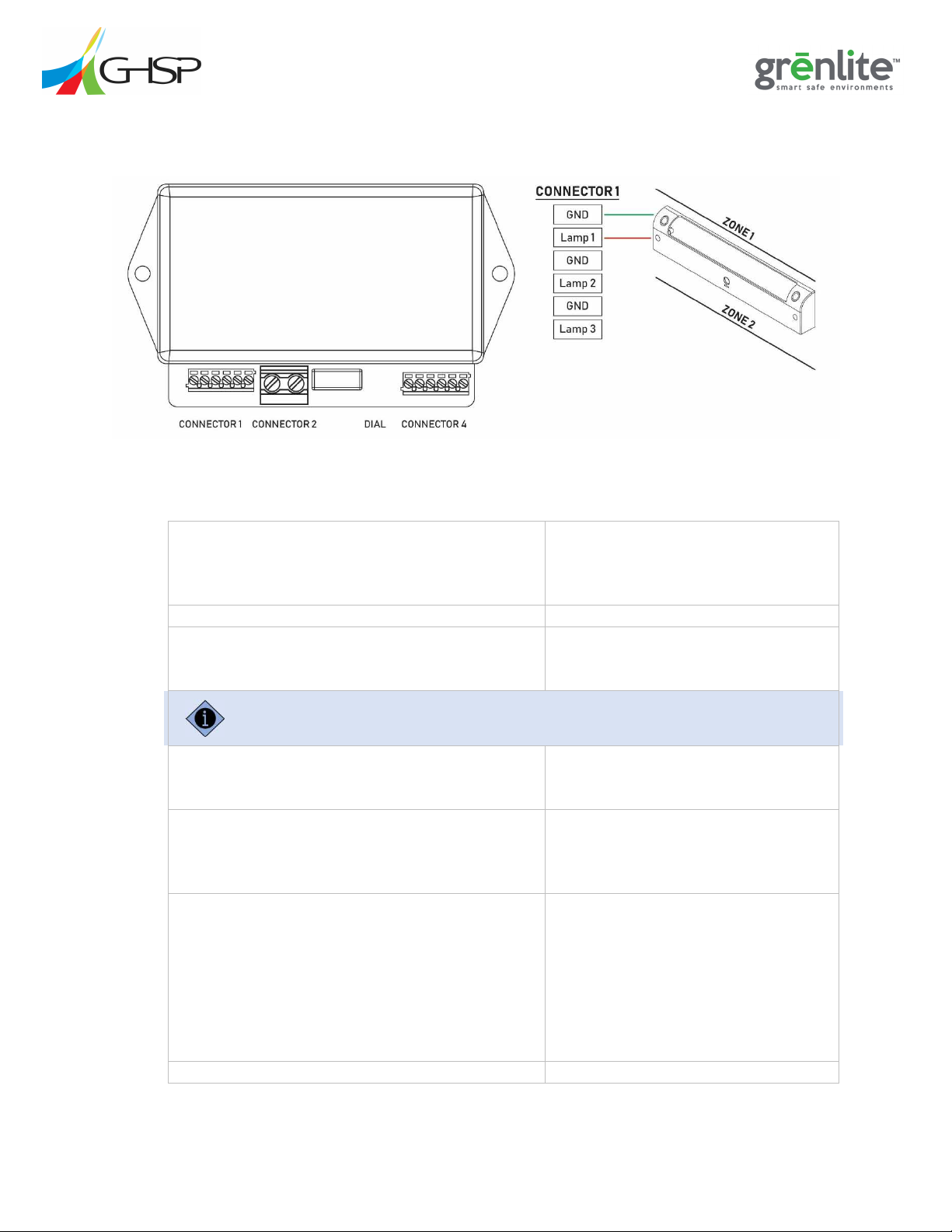

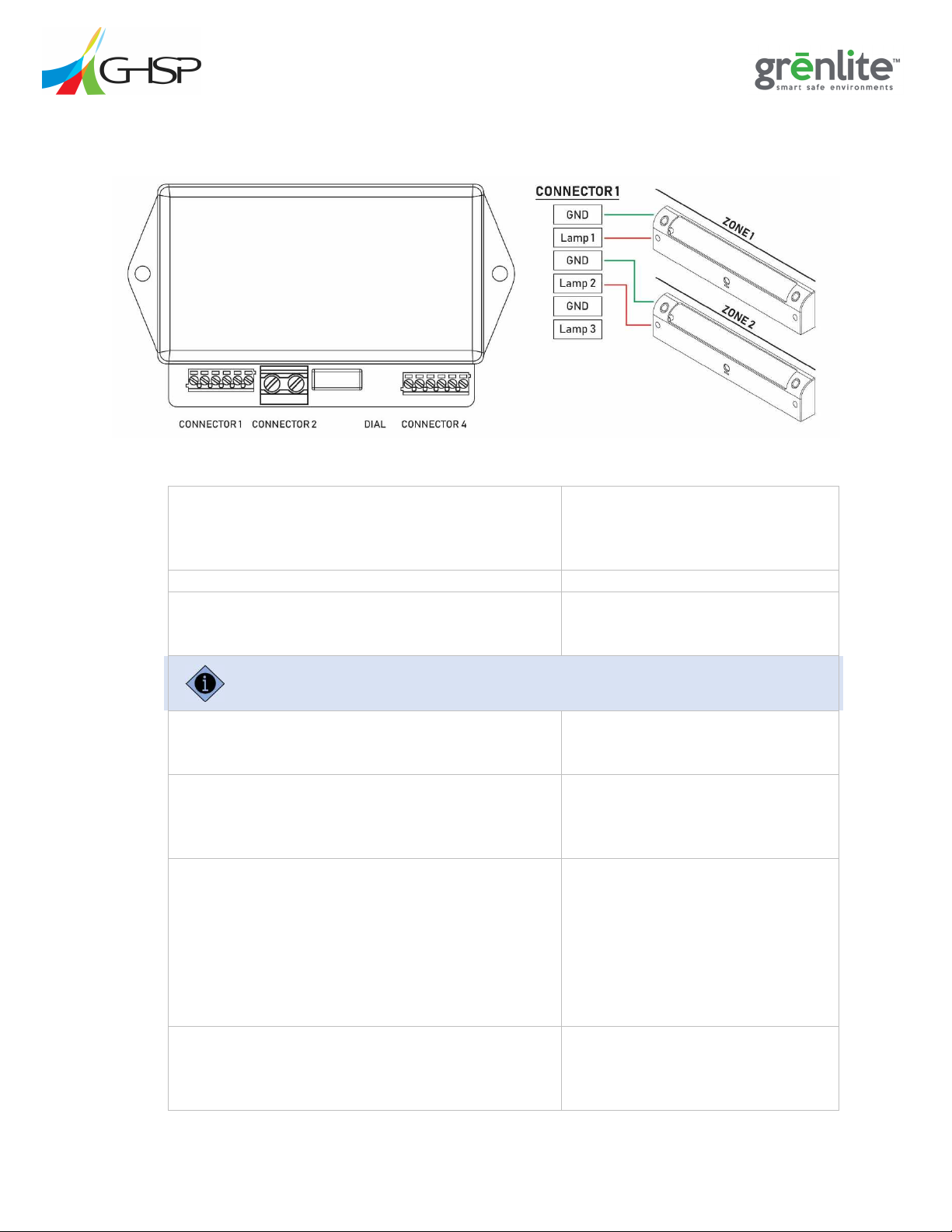

The system uses the following omponents with integrated ele tri al onne tions.

Dosing units

o400mm grēnlite lamp

o200mm grēnlite lamp

1 mating ele tri al onne tor, per dosing unit