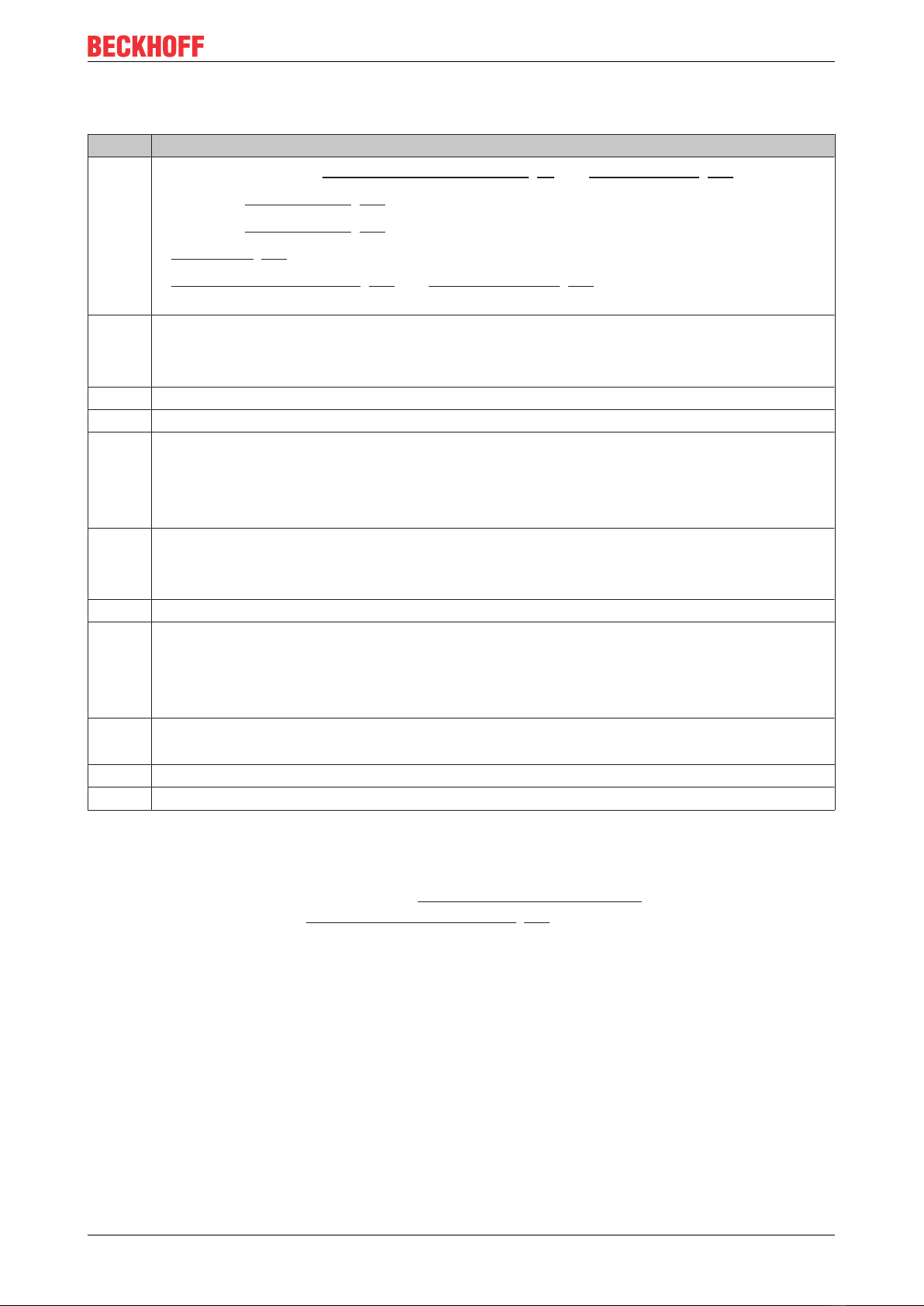

Table of contents

EP1908 3Version: 3.0.0

Table of contents

1 Notes on the documentation....................................................................................................................5

1.1 Disclaimer..........................................................................................................................................5

1.1.1 Trademarks........................................................................................................................5

1.1.2 Patents...............................................................................................................................5

1.1.3 Limitation of liability............................................................................................................6

1.1.4 Copyright............................................................................................................................6

1.2 Documentation issue status ..............................................................................................................7

1.3 Staff qualification...............................................................................................................................8

1.4 Safety and instruction........................................................................................................................9

1.4.1 Explanation of symbols ......................................................................................................9

1.5 Beckhoff Support and Service.........................................................................................................10

2 For your safety ........................................................................................................................................11

2.1 Duty of care.....................................................................................................................................11

2.2 Safety image signs..........................................................................................................................12

2.3 General safety instructions..............................................................................................................13

2.3.1 Before operation...............................................................................................................13

2.3.2 In operation ......................................................................................................................13

2.3.3 After operation..................................................................................................................13

3 System description .................................................................................................................................14

3.1 EtherCAT Box Modules...................................................................................................................14

4 Product description ................................................................................................................................15

4.1 EP1908-0002 ..................................................................................................................................15

4.2 Intended use ...................................................................................................................................16

4.3 Technical data.................................................................................................................................17

4.4 Safety parameters...........................................................................................................................18

4.5 Characteristic curve of the inputs....................................................................................................18

4.6 Dimensions .....................................................................................................................................19

5 Operation .................................................................................................................................................20

5.1 Environmental conditions ................................................................................................................20

5.2 Installation .......................................................................................................................................20

5.2.1 Safety instructions............................................................................................................20

5.2.2 Transport / storage...........................................................................................................20

5.2.3 Address settings on the TwinSAFE EtherCAT Box..........................................................21

5.2.4 Mounting ..........................................................................................................................21

5.2.5 Connection.......................................................................................................................22

5.2.6 Signal cables....................................................................................................................28

5.2.7 Description of the EP1908 test pulses .............................................................................29

5.2.8 TwinSAFE reaction times.................................................................................................31

5.3 Operation modes.............................................................................................................................32

5.4 EP1908 process image ...................................................................................................................33

5.5 Diagnostics......................................................................................................................................34

5.5.1 Run LED diagnostics........................................................................................................34

5.5.2 Diagnostic objects............................................................................................................35