INSTALLATION INSTRUCTIONS #615598

CAREFULLY READ INSTRUCTIONS BEFORE STARTING INSTALLATION

When installing this exhaust system make sure to use proper safety precautions. Use jack stands when working under

the vehicle, set parking brake, block tires and use safety glasses and gloves. Allow exhaust to cool before attempting

installation. Severe injury or burns could occur if safety measures are not taken.

SUGGESTED TOOLS: 1/2”, 9/16” 15mm wrenches & sockets, WD-40, hacksaw, jack stands.

2. To remove stock exhaust

unbolt it from the 2 bolt flange

located in front of your stock

muffler. You will reuse the

factory nuts. Cut your stock

tailpipe off for easier removal of

stock exhaust. Use WD-40 to

disengage hangers from rubber

grommets. Do not damage or

remove the rubber grommets as

you will reuse them to mount

your new system.

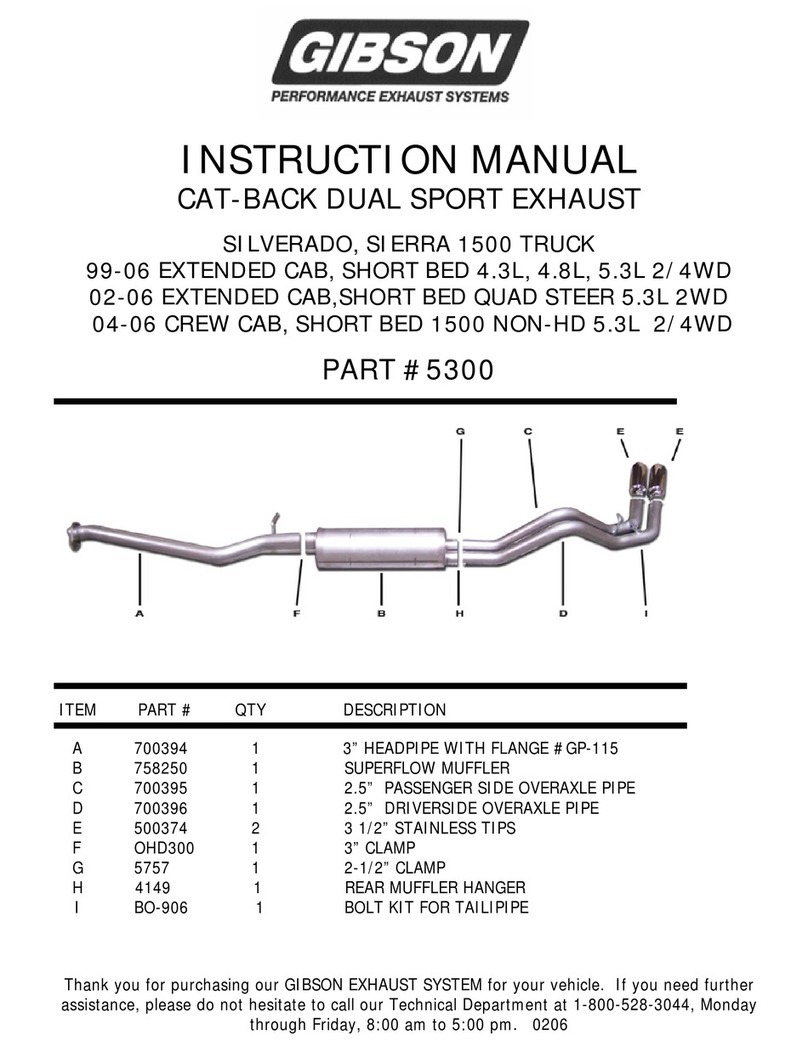

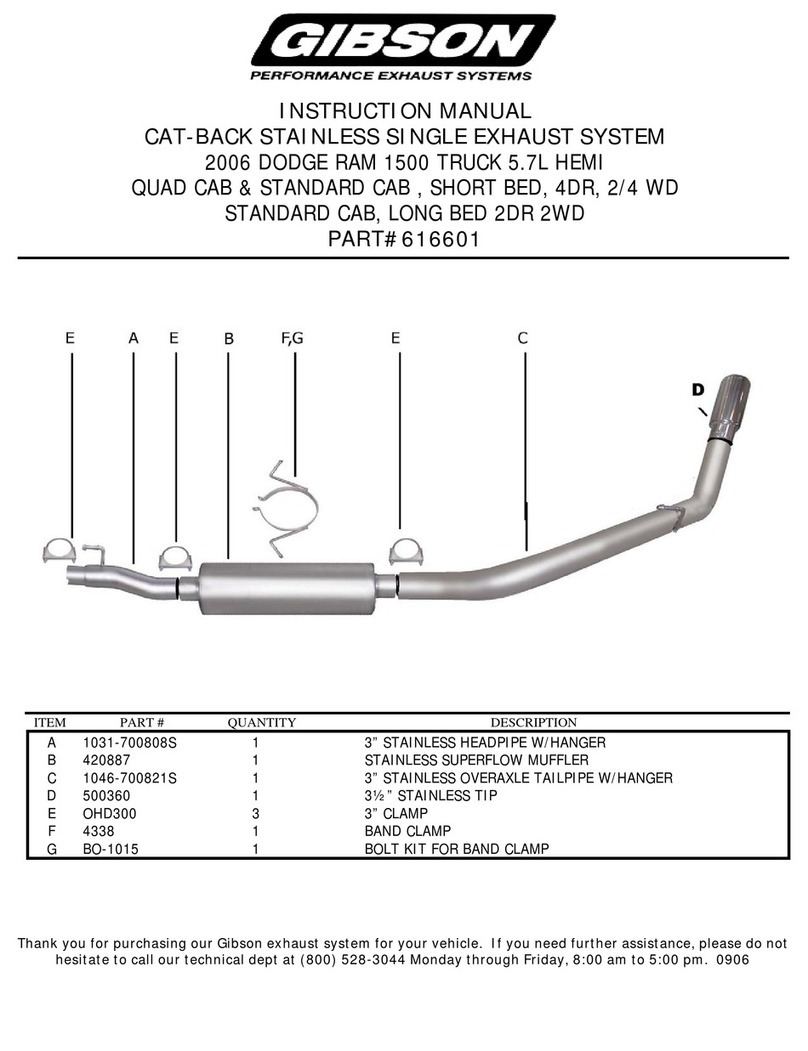

5. Install overaxle tailpipe #C

into muffler 1 ½” – 2”. Use

clamp #F to secure pipe to

muffler. Do not tighten.

GIBSON EXHAUST systems are designed on a factory stock vehicle. Any aftermarket products installed could increase the sound

levels of this Exhaust.

Make sure there is a 1” clearance from ALL rubber brake lines, shock boots, fuel lines, tires, etc to prevent heat

related damage or fire.

4. Slide muffler #B onto headpipe

1 ½”-2”. Use jack stand to

support muffler. Use clamp #F to

secure muffler to headpipe.

Next, install band clamp #G onto

muffler. Insert hanger into rubber

grommet. Use bolt kit #H to

secure band clamp. Do not

tighten.

3. Install headpipe #A onto your

exisiting 2-bolt flange reuse your

factory nuts to secure. Do not

tighten. Insert welded hanger

onto rubber grommets.

6. Slide exit pipe #D onto

overaxle tailpipe. Insert welded

hanger into rubber grommet.

Use clamp#F to secure pipes

together. Do not tighten. Rotate

pipe until level.

7. Install stainless steel tip #E.

Clamp down. When you have

everything in place, firmly

tighten all bolts and clamps

down securely. Use stainless

steel cleaner and a Scotch Brite

pad weekly to prevent tip from

discoloration. Inspect all

fasteners after 25-50 miles of

operation and re-tighten as

necessary.

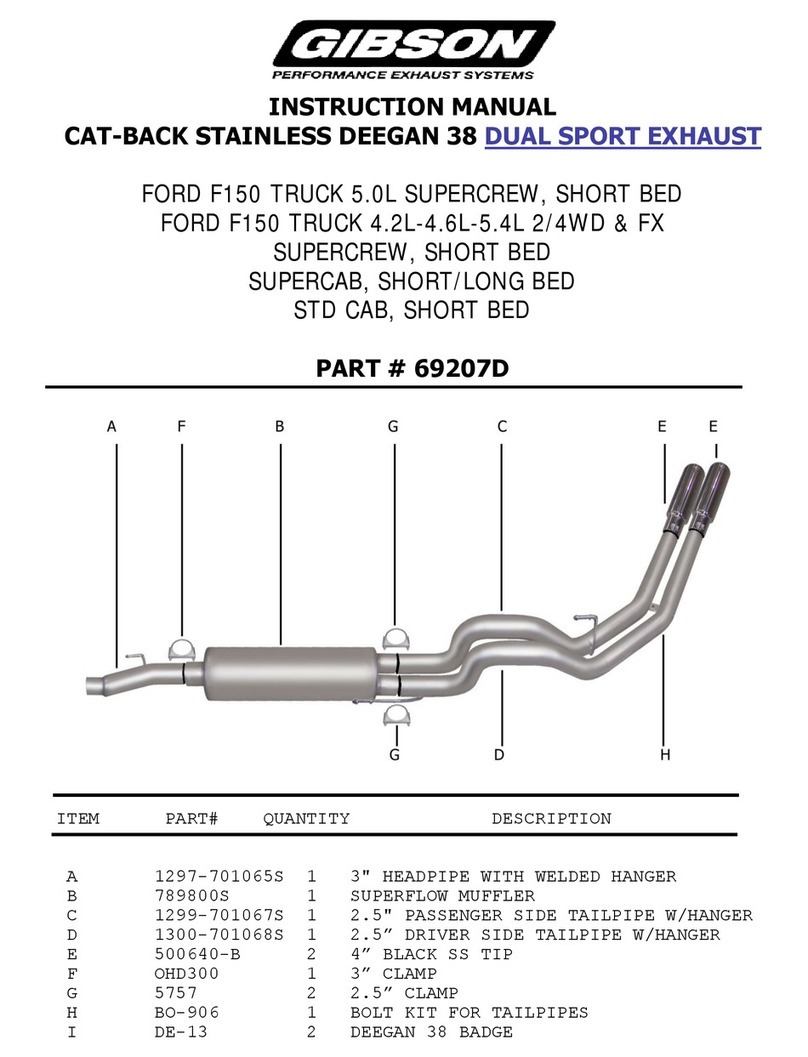

1. Disconnect the negative battery cable before removal of OEM exhaust. This will allow the computer to reset and

recognize the new exhaust. Lay out the exhaust on the floor so it looks like the drawing and compare parts with manual.