Contents

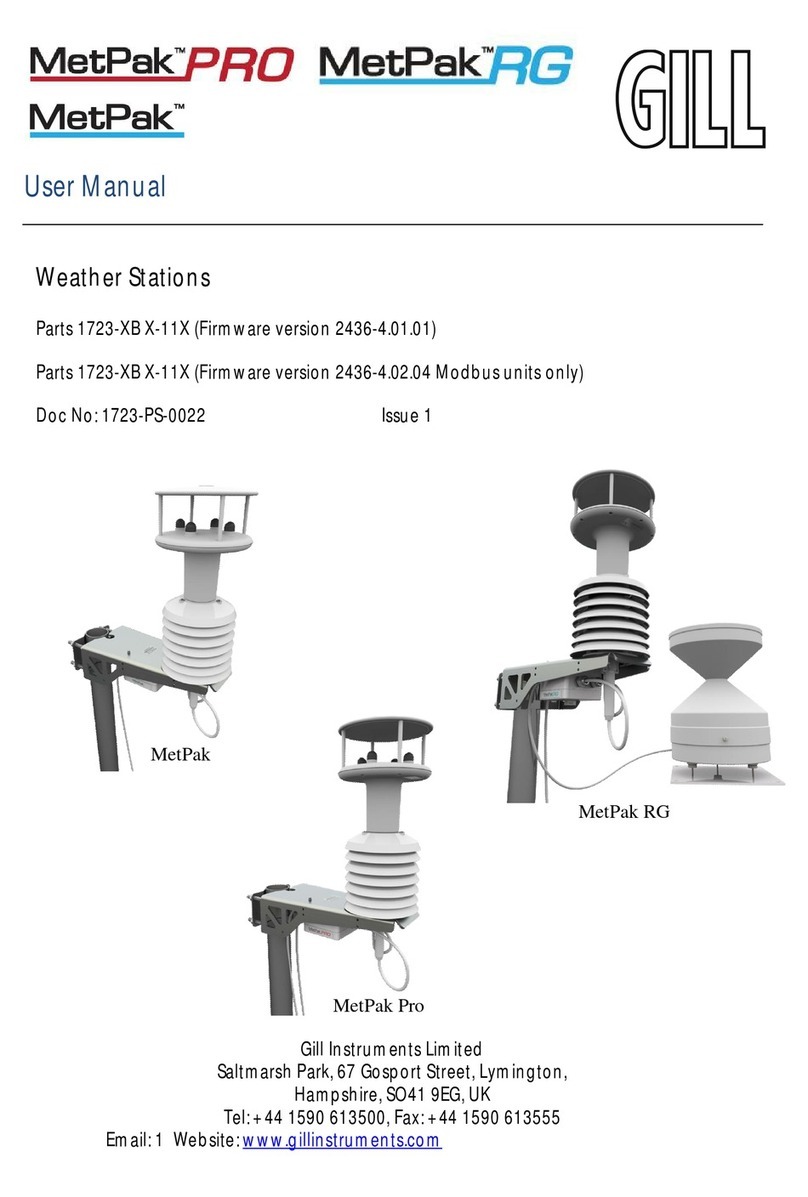

MetPak RG User Manual

Last Change ©Gill Instruments Ltd

12 March, 2013 Page 1

Contents

1. Introduction.........................................................................................................1

1.1 Principle of Operation......................................................................................................2

1.1.1 Wind Speed and Direction Sensor..................................................................... 2

1.1.2 Radiation Shield................................................................................................ 3

1.1.3 Temperature and Relative Humidity Sensor with Dewpoint Output.................... 3

1.1.4 Barometric Pressure.......................................................................................... 3

1.1.5 Rain Sensor (DIG1 Input)..................................................................................3

1.2 Abbreviations.................................................................................................................. 4

2. Installation...........................................................................................................5

2.1 Pre-Installation Checks...................................................................................................5

2.2 Installation....................................................................................................................... 6

2.2.1 Bench System Test........................................................................................... 6

2.2.2 Bench Test Equipment Required.......................................................................6

2.2.3 Cabling.............................................................................................................. 6

2.2.4 Communication and Power Connections........................................................... 9

2.2.5 Digital Rain Gauge Connections......................................................................13

2.2.6 Mounting MetPak RG...................................................................................... 14

2.2.7 Mounting the Rain Gauge................................................................................16

3. Operation...........................................................................................................19

3.1 Start Guide....................................................................................................................19

3.2 MetView........................................................................................................................ 21

3.2.1 Opening MetView............................................................................................ 21

3.2.2 Scanning for Devices....................................................................................... 22

3.2.3 The MetView Console ..................................................................................... 23

3.2.4 MetView Console Display Options................................................................... 25

3.2.5 MetView Gauge Ranges and Graphs.............................................................. 26

3.2.6 Data logging.................................................................................................... 28

3.3 MetPak RG Configuration ............................................................................................. 31

3.4 Configuring MetPak RG with MetSet............................................................................. 33

3.4.1 Opening MetSet .............................................................................................. 33

3.4.2 MetSet Editing Screen..................................................................................... 35

3.4.3 Monitoring MetPak RG Output Data Using HyperTerminal.............................. 40

3.4.4 Configuring MetPak RG for SDI-12.................................................................. 42

3.4.5 SDI-12 Commands.......................................................................................... 42

3.4.6 Safe Mode.......................................................................................................46