Gillison Forklift Manual

- SAFETY2

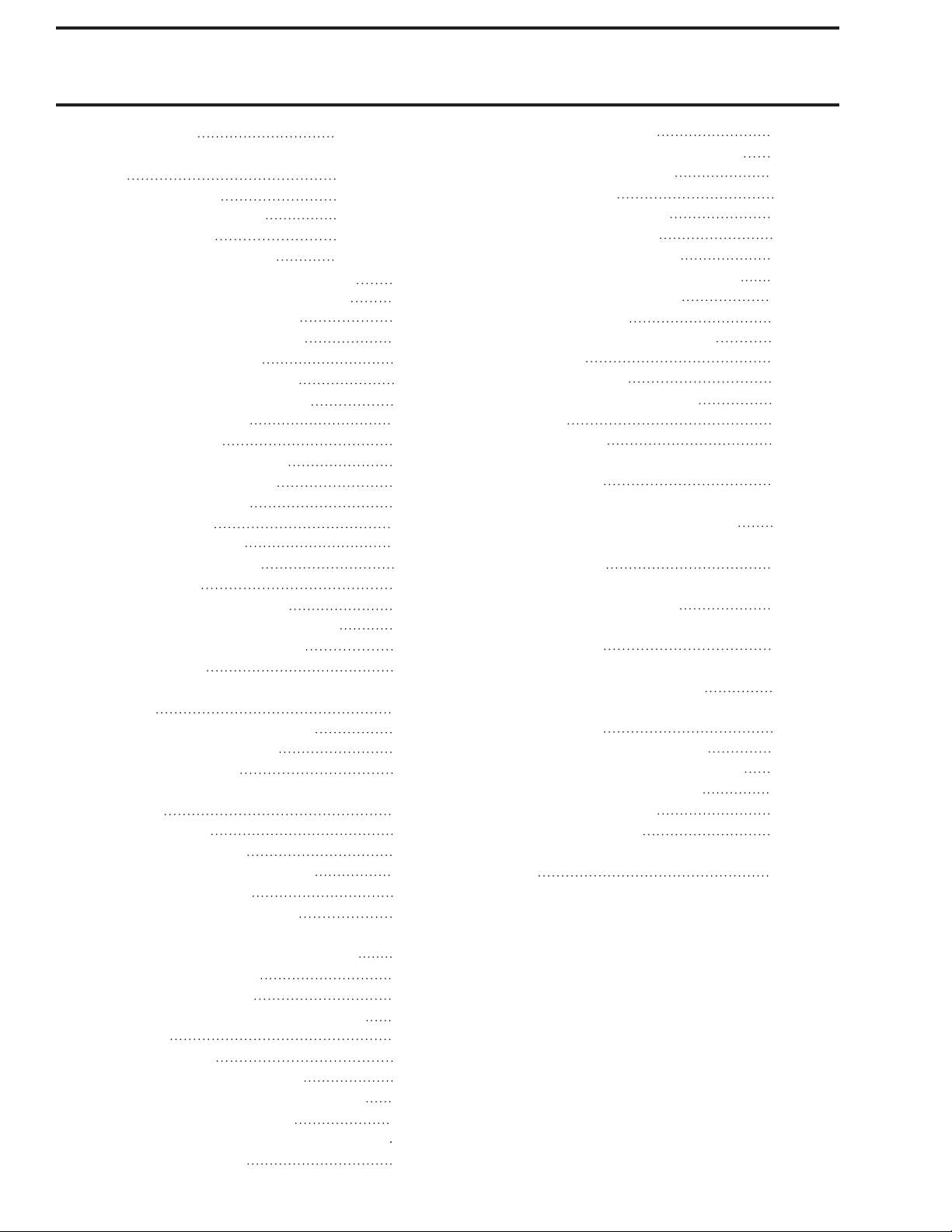

INTRO TO SAFETY

The safety of the operator is one of the main concerns

in designing a new piece of equipment. Designers build

in as many safety features as possible. However, ev-

ery year many accidents occur which could have been

avoided by a few seconds of thought and a more care-

ful approach to handling equipment. You, the operator,

can avoid many accidents by observing the following

precautions. To avoid personal injury, study the follow-

ing precautions and insist those working with you or for

you to follow them.

In order to provide a better view, certain photographs

or illustrations in this manual may show an assembly

with a safety shield removed. However, the equipment

should never be operated in this condition. Keep all

shields in place. If shield removal becomes necessary

for repairs, replace shield prior to further operation.

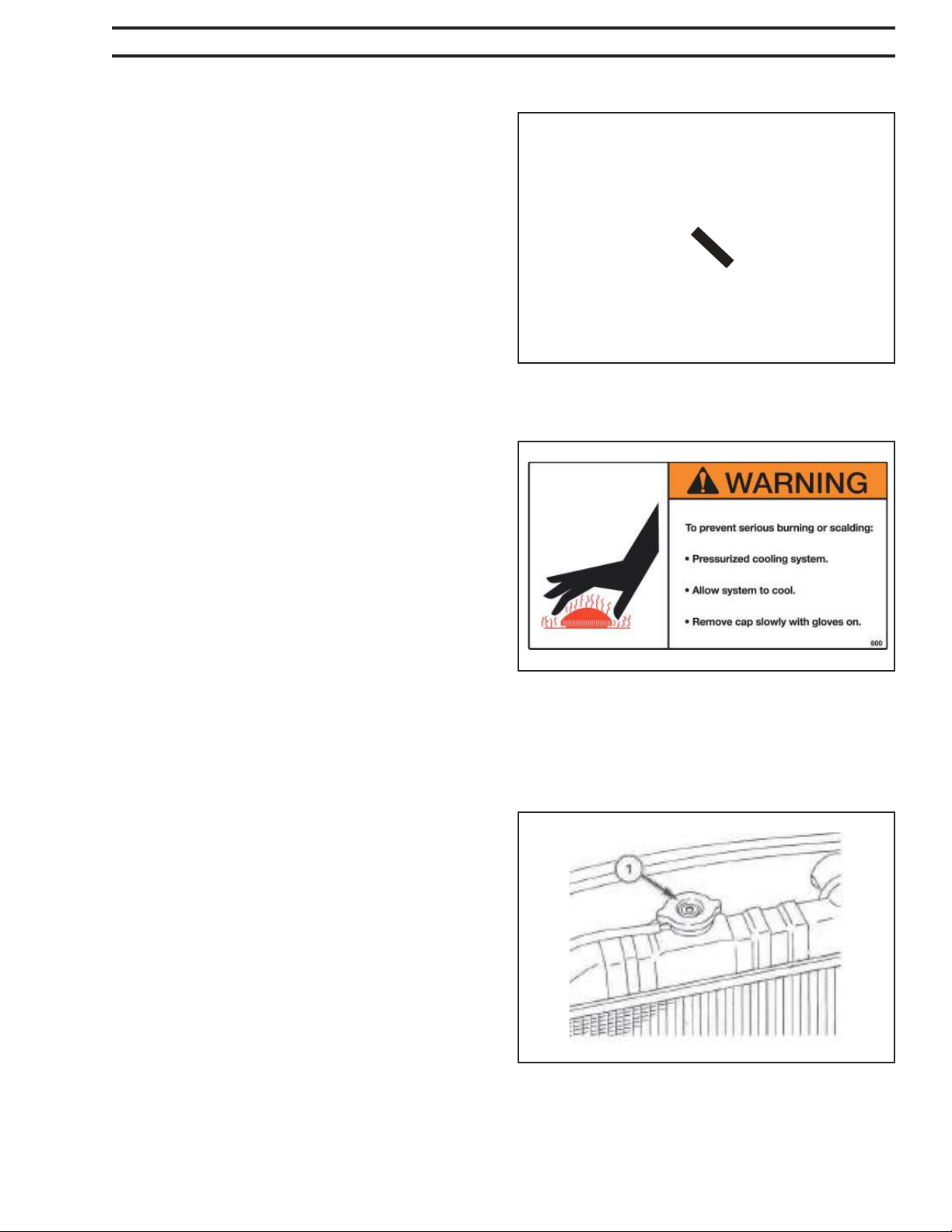

SAFETYALERT SYMBOL

FIG. 1: This is the safety alert symbol. It means AT-

TENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED! Look for it, both in this manual and on

safety decals on the equipment. It will direct your at-

tention to information that involves your safety and the

safety of others.

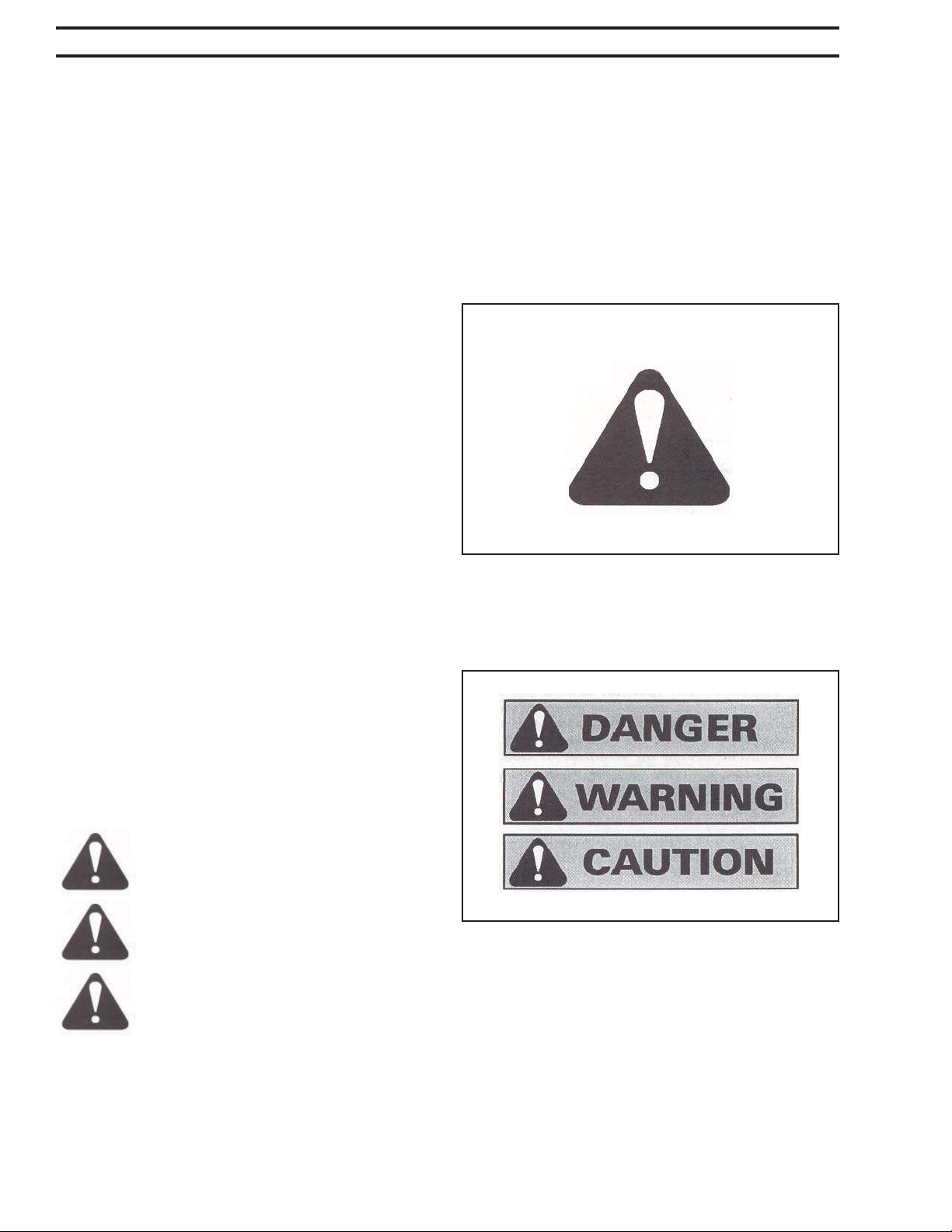

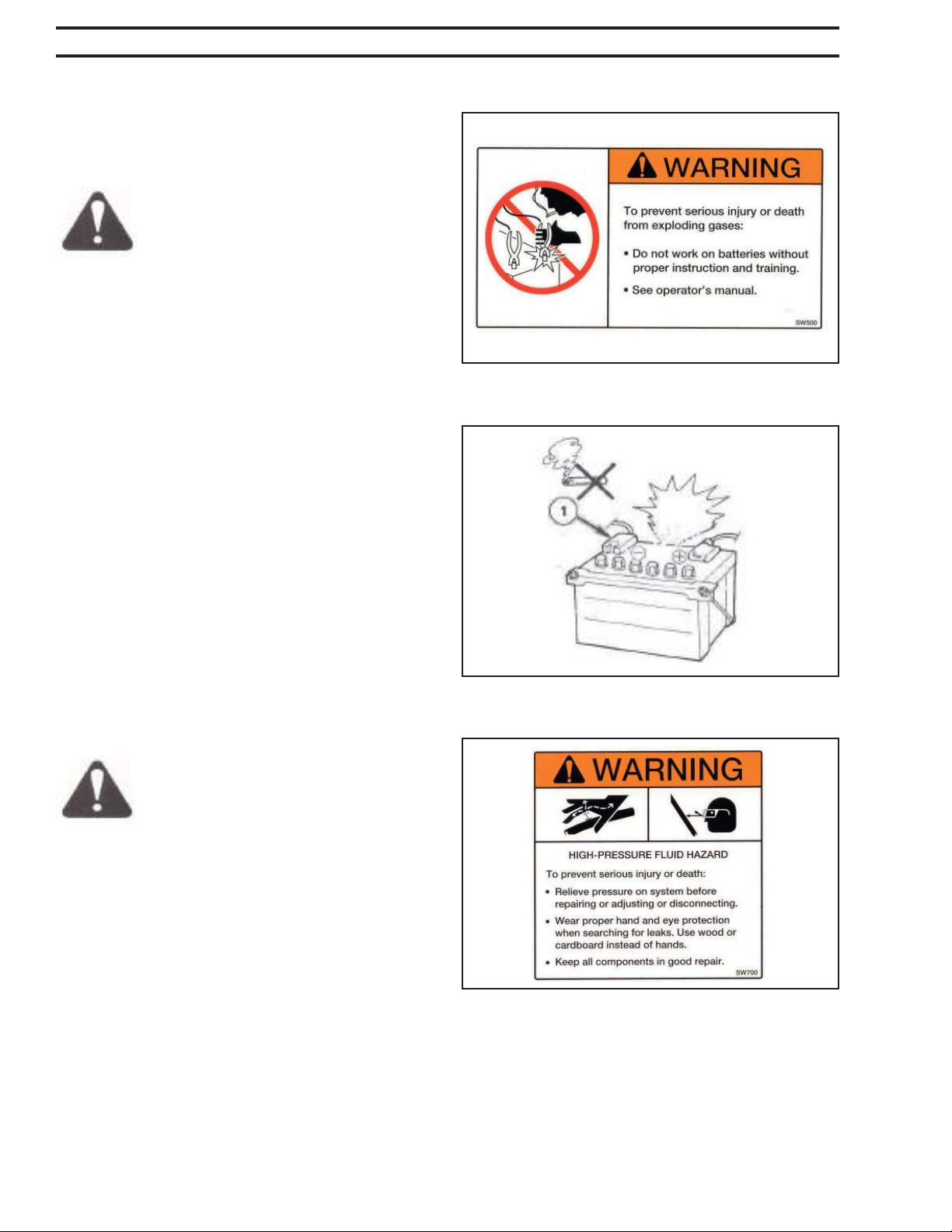

SIGNALWORDS

FIG. 2: The words DANGER, WARNING, or CAU-

TION are used with the safety alert symbol. Learn to

recognize these safety alerts, and follow the recom-

mended precautions and safe practices.

DANGER indicates an imminently haz-

ardous situation that, if not avoided, will

result in death or serious injury.

WARNING indicates an imminently

hazardous situation that, if not avoided,

could result in death or serious injury.

CAUTION indicates an imminently

hazardous situation that, if not avoided,

could result in minor or moderate inju-

ry.

Replace any DANGER, WARNING, CAUTION or in-

structional decal that is not readable or is missing. The

locations and part numbers of these decals are identified

later in this section of the manual.

FIG. 1

FIG. 2

SAFETY