Table of Contents

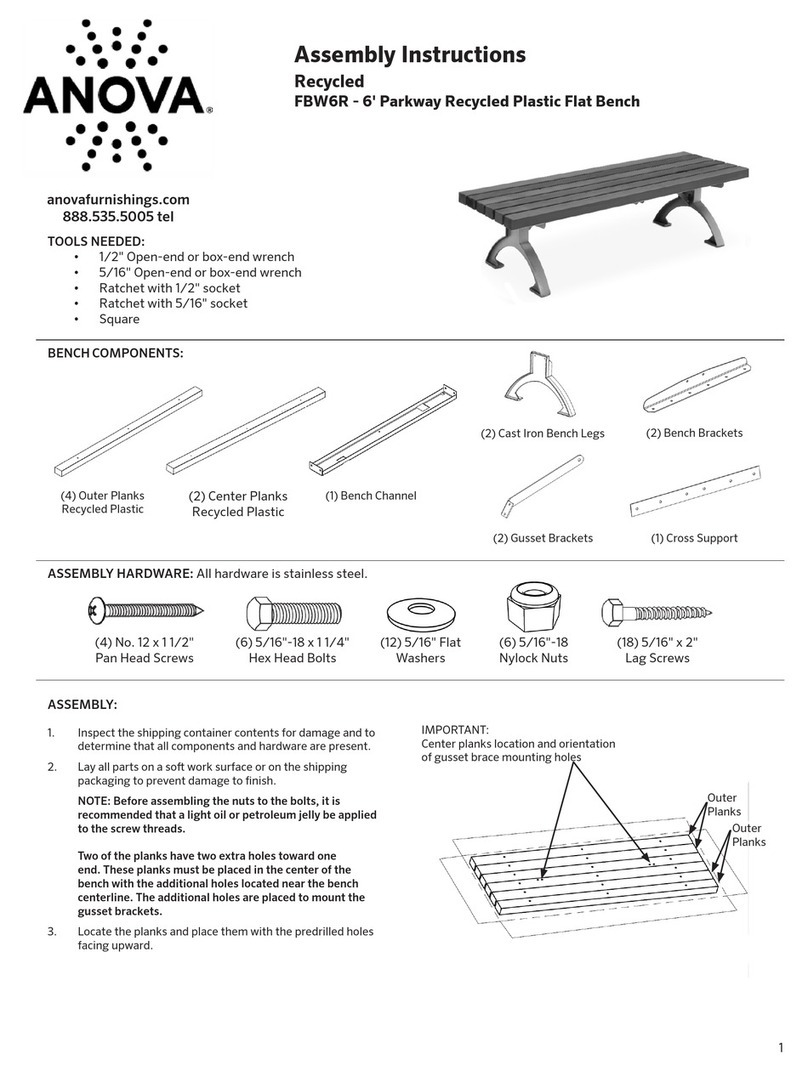

We do not provide the screws for fixing-anchoring to the wall and/or foundations. The fitter must choose the adequate rod/screw/plug/

nut/washer system for fixing and flushing to the foundations and/or wall based on the nature of these surfaces.

In any case, the screws must be in stainless steel.

1. Installation ..................................................................................................................................................................... 4

1.1 Installing the fixation for the column base................................................................................................................................4

1.2 Joining the surface manifolds ....................................................................................................................................................... 7

1.3 Fixing closing beams.........................................................................................................................................................................8

1.4 Assembling the sides .......................................................................................................................................................................9

1.5 Electric pre-installation...................................................................................................................................................................10

1.6 Side joints with closing beam ...................................................................................................................................................... 11

1.7 Joining with opening beam .......................................................................................................................................................... 12

1.8 Joining with central beam ............................................................................................................................................................ 13

1.9 Installing the slats ............................................................................................................................................................................ 15

1.10 Installing the transmission plate ...............................................................................................................................................17

1.11 Installing the “U” profile ................................................................................................................................................................. 18

1.12 Drainage channel closed column ........................................................................................................................................... 20

1.13 Motor installation ............................................................................................................................................................................. 21

2. Electrical connections ...........................................................................................................................................22

The connection of the electrical installation must be done adhering to the current regulations for low voltage (REBT).

2.1 Teleco documentation.................................................................................................................................................................... 22

2.2 Somfy documentation................................................................................................................................................................... 22

2.3 Installation of automatic devices on beams........................................................................................................................ 22

2.4 Perimeter LED installation........................................................................................................................................................... 23

3. Installing column cup .............................................................................................................................................24

4. Maintenance...............................................................................................................................................................25

Before assembling, please read the maximum tightening torque for each type of screw, as indicated in this section.

Annex I Disassembly and disposal of packaging and product components at the end of the product’s service life ..26

Annex II Warranty certificate .......................................................................................................................................... 30

Bioclimatic Pergola installation check sheet...............................................................................................................32