2GIOVENZANA INTERNATIONAL B.V. - MT-FGR1-EN / 28.06.2021 - Rev. 4

INTRODUCTION

Terms of use

Special conditions for a safe usage

GIOVENZANA INTERNATIONAL B.V.

Terms of use

Special conditions for a safe usage

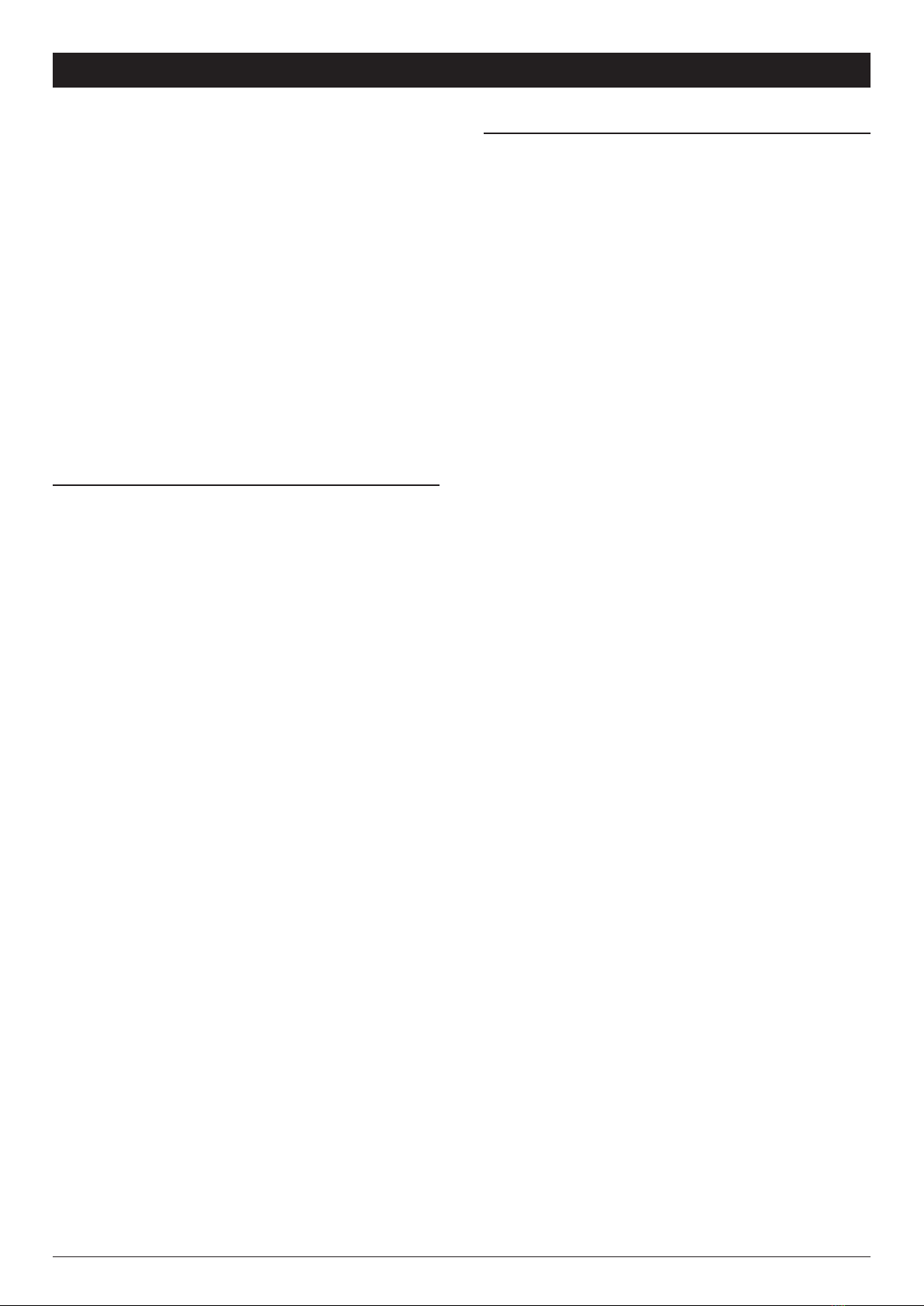

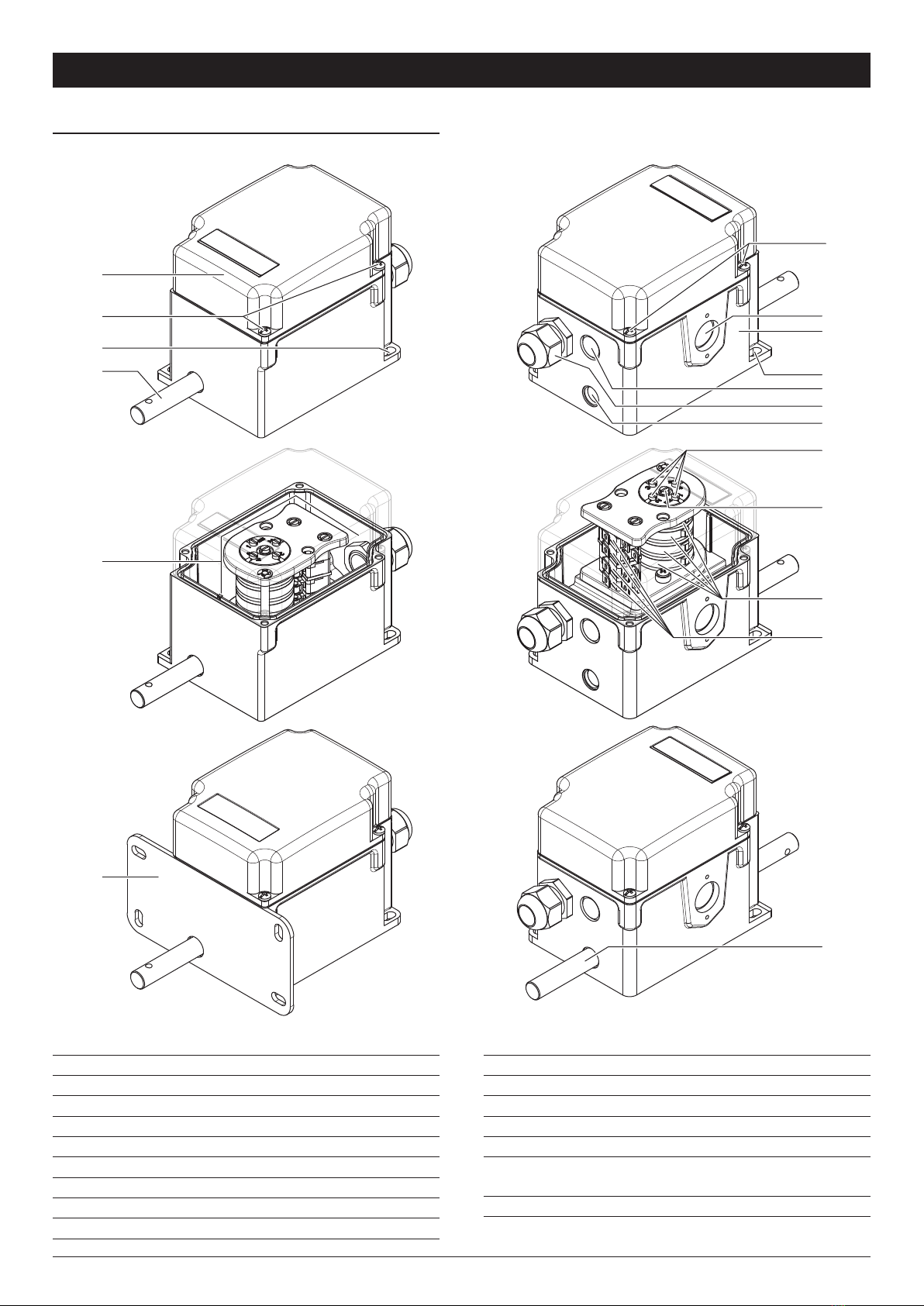

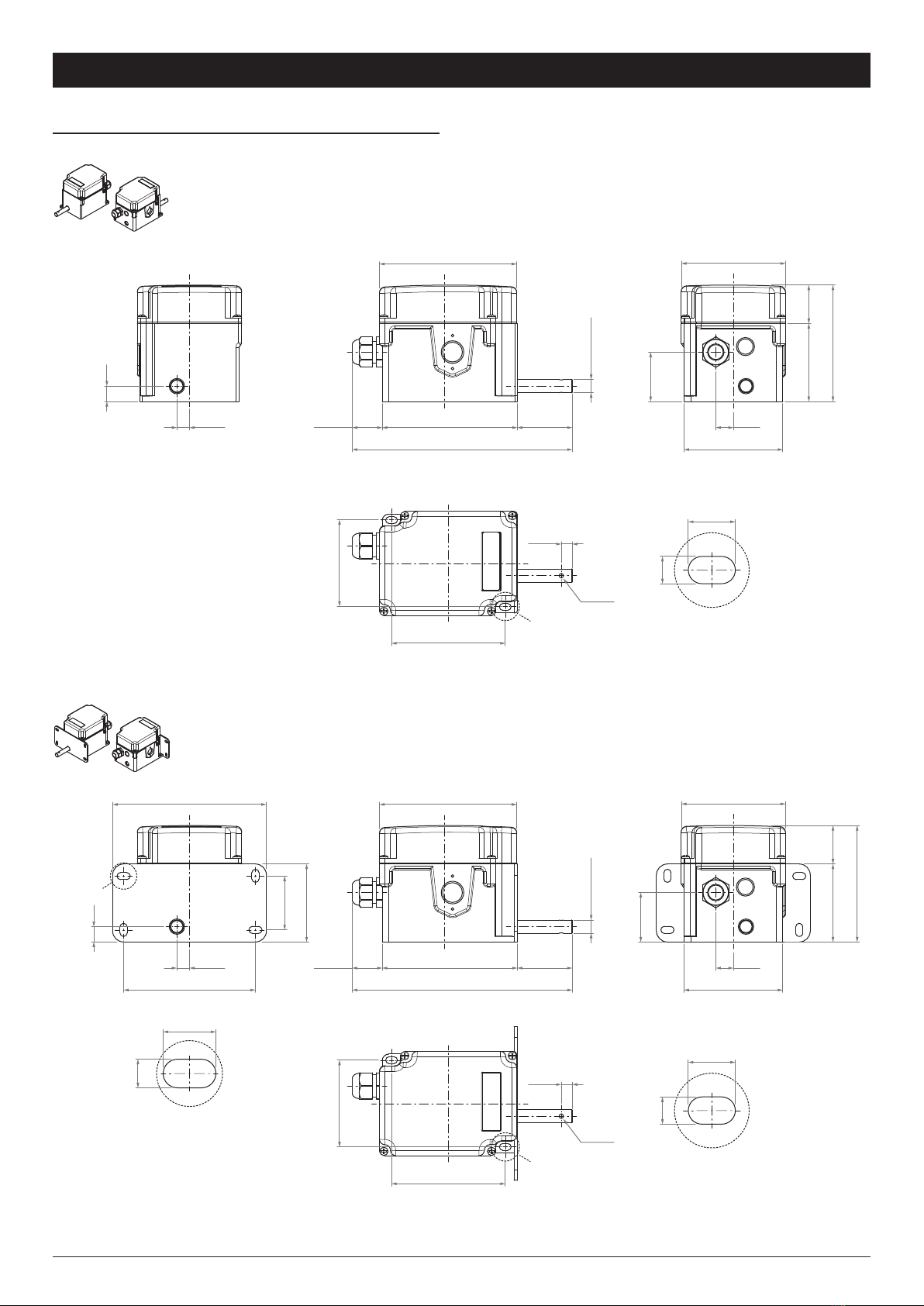

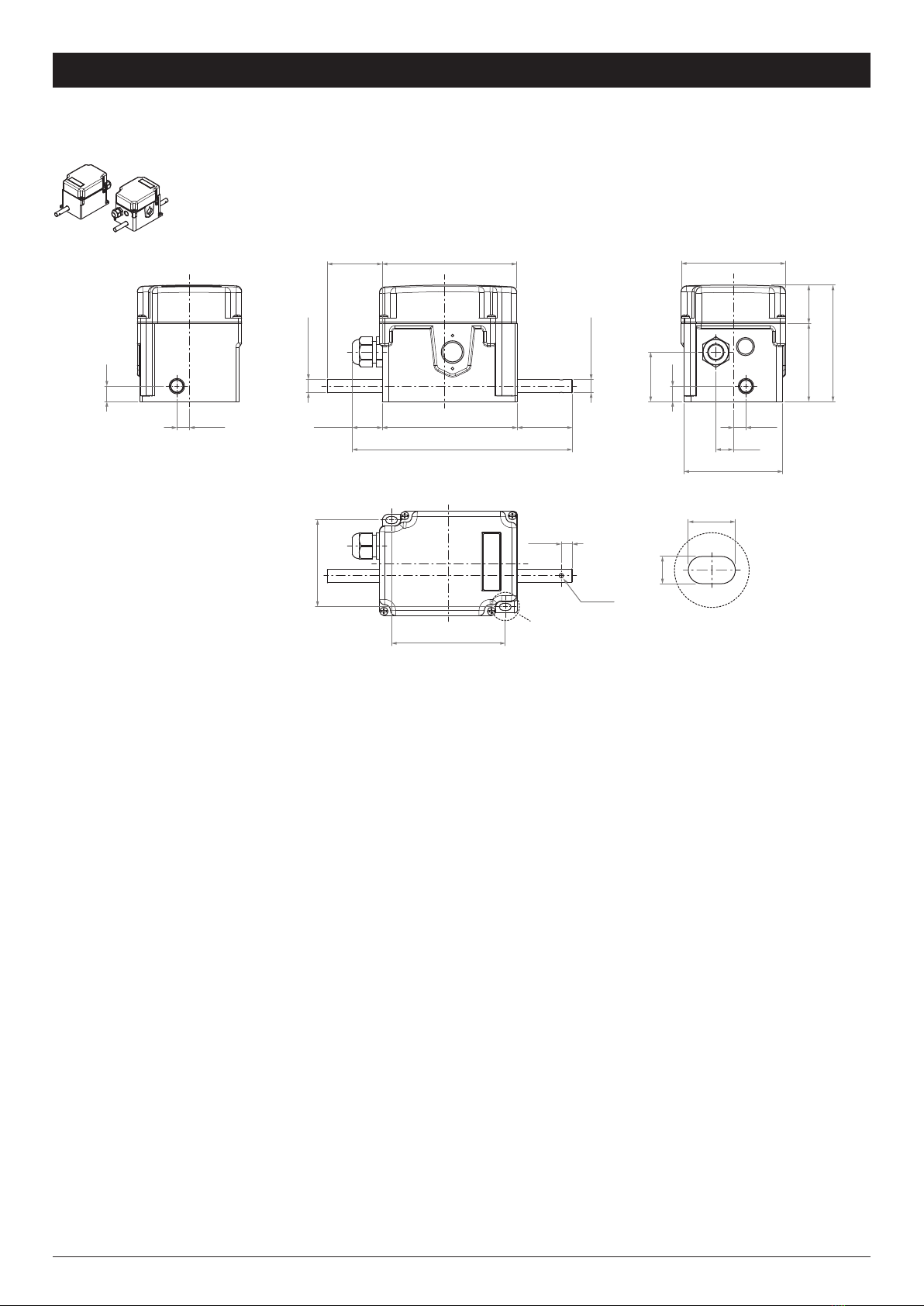

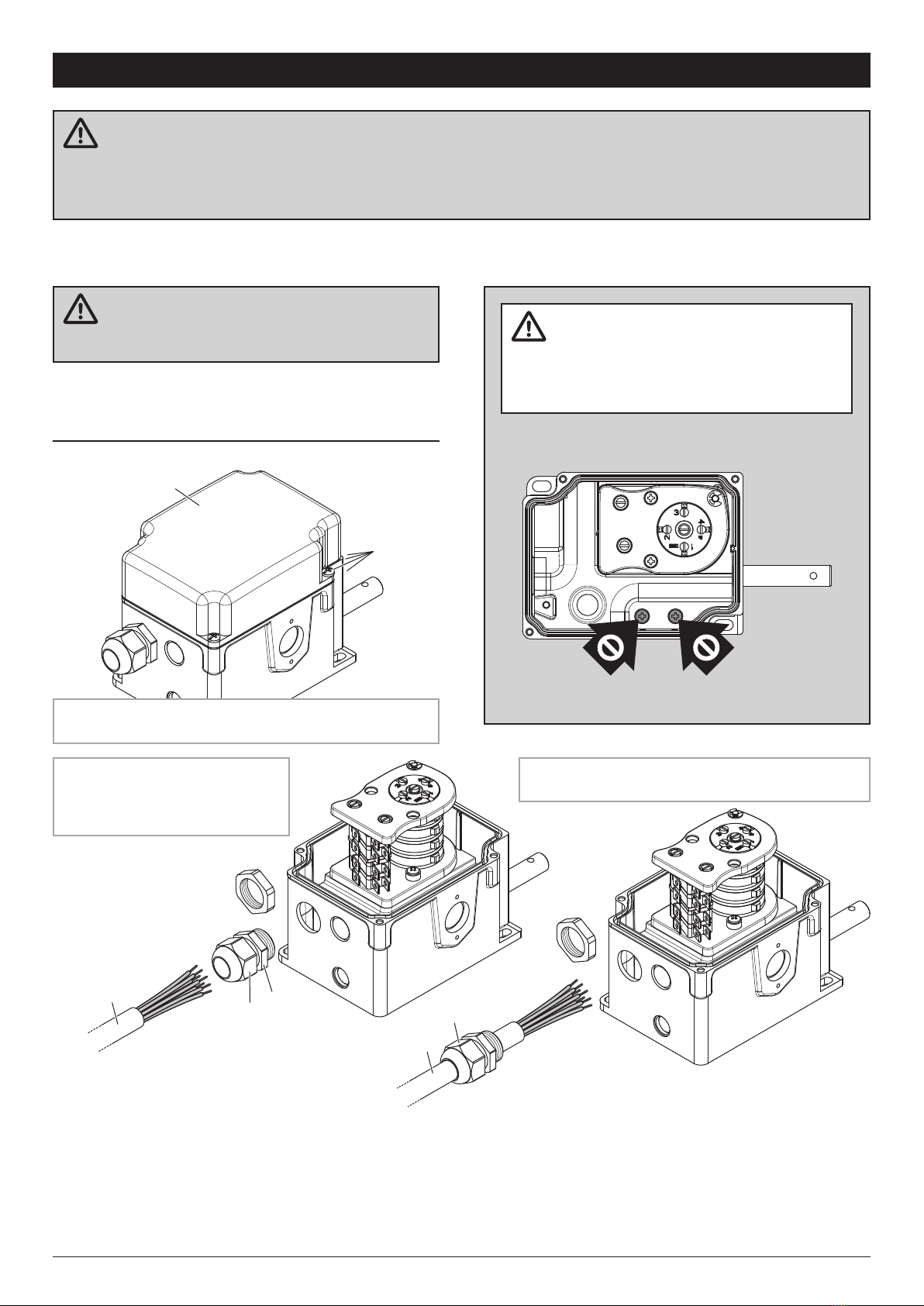

The FGR rotary gear limit switch is a device used to

control the number of turns or the rotation/direction

angle of industrial and building machines.

A typical application is the rolling shutter door,

overhead cranes or tackles etc. The unit, throught a

gear system and cams transmission, controls 2 or

more microswitches so, after a determined number of

revolutions, it can prepare the motor to start or stop run.

The microswitches have a calibration screw that

operates independently on each cam; so it can calibrate

the opening and closing of each micro according the

functional requirements needed.

The system gear transmission allows you to choose

different ratios with the main shaft.

The equipment must be installed only if it is completely

intact and unbroken. The product must be installed

according to the applicable code of practice, national

regulations and laws and / or international standards as

well as in compliance with the present instructions.

Do not change anything inside or outside the

equipment.

Low mechanical risk

The equipment is suitable for resisting impact energies

up to 4 J.

When impacts of energy are likely greater than 4 J,

additional mechanical protection is required around the

plastic case.

Potential electrostatic risk

The equipment is intended for fixed use and the user

must not frequently touch the equipment in service

(except for maintenance).

To avoid the potential electrostatic charge, it is

necessary to perform the following instructions during

the installation and service of the FGR:

• Do not install under direct air or other gas flow. If

these requirements cannot be met, additional external

direct flow protection is required.

• Install only when the relative humidity of the

environment is greater than 30% (stable, always or

for a long time) or in an environment with a humidity

control system.

• The metal parts of the casing must be connected

to the equipotential system in accordance with the

instructions in paragraph “Connection of earthing or

bonding conductors”.

• Do not rub the plastic cover insistently. If cleaning is

required (e.g. to remove dust) only manual operations

with wet materials are allowed.

Conditions

• The inner components (cam MFI micros, mounting

brackets, etc.) are mounted in order to guarantee the

type of protection.

• Any modification is forbidden.

• Do not remove any components or micro even if they

are not used.

Types of protection

• Every screw shall be tightened with the tightening

torque according to this document, to maintain the

degree of protection IP.

• Additional holes and/or entries into enclosure are

forbidden, the only entries in the enclosure shall be

made by Giovenzana (see the information reported in

clause 1 of this document).

• The type of protection and minimum degree of

protection (IP code) of the entries into enclosure

or cable glands shall be in accordance with the

equipment marking.

• Any entry of the enclosure, the mounting of the entries

into enclosure or cable glands shall be carried out to

maintain the level of protection of the equipment.

Connection of earthing or bonding conductors

The equipment shall be earthed in accordance with the

relevant code of practice. The equipment is provided by

internal connection terminal for earthing.

If the reference standards applicable for the installation

require an external equipotential connection or these

become necessary for other reasons, connect the

equipotential conductor to the external earth terminal,

identified with the earthing symbol.

The conductors used for the earth and equipotential

connection must be equipped with an eye lug. Install

each conductor according to the following instructions:

• Place the eyelet in contact with the threaded hole of

the internal or external earth terminal, positioned on

the metal box.

• Place a Grover washer or non-loosening washer

between the eye lug and the clamp screw.

• Tighten the ground terminal screw with a tightening

torque of 1.7 N×m (15 lb×in). On the internal earth

screw add some threadlocker. Tightening the screw

ensures electrical continuity.

INTRODUCTION

GIOVENZANA INTERNATIONAL B.V.

Terms of use

Special conditions for a safe usage

The FGR rotary gear limit switch is a device used to

control the number of turns or the rotation/direction

angle of industrial and building machines.

A typical application is the rolling shutter door,

overhead cranes or tackles etc. The unit, throught a

gear system and cams transmission, controls 2 or

more microswitches so, after a determined number of

revolutions, it can prepare the motor to start or stop run.

The microswitches have a calibration screw that

operates independently on each cam; so it can calibrate

the opening and closing of each micro according the

functional requirements needed.

The system gear transmission allows you to choose

different ratios with the main shaft.

The equipment must be installed only if it is completely

intact and unbroken. The product must be installed

according to the applicable code of practice, national

regulations and laws and / or international standards as

well as in compliance with the present instructions.

Do not change anything inside or outside the

equipment.

Low mechanical risk

The equipment is suitable for resisting impact energies

up to 4 J.

When impacts of energy are likely greater than 4 J,

additional mechanical protection is required around the

plastic case.

Potential electrostatic risk

The equipment is intended for fixed use and the user

must not frequently touch the equipment in service

(except for maintenance).

To avoid the potential electrostatic charge, it is

necessary to perform the following instructions during

the installation and service of the FGR:

• Do not install under direct air or other gas flow. If

these requirements cannot be met, additional external

direct flow protection is required.

• Install only when the relative humidity of the

environment is greater than 30% (stable, always or

for a long time) or in an environment with a humidity

control system.

• The metal parts of the casing must be connected

to the equipotential system in accordance with the

instructions in paragraph “Connection of earthing or

bonding conductors”.

• Do not rub the plastic cover insistently. If cleaning is

required (e.g. to remove dust) only manual operations

with wet materials are allowed.

Conditions

• The inner components (cam MFI micros, mounting

brackets, etc.) are mounted in order to guarantee the

type of protection.

• Any modification is forbidden.

• Do not remove any components or micro even if they

are not used.

Types of protection

• Every screw shall be tightened with the tightening

torque according to this document, to maintain the

degree of protection IP.

• Additional holes and/or entries into enclosure are

forbidden, the only entries in the enclosure shall be

made by Giovenzana (see the information reported in

clause 1 of this document).

• The type of protection and minimum degree of

protection (IP code) of the entries into enclosure

or cable glands shall be in accordance with the

equipment marking.

• Any entry of the enclosure, the mounting of the entries

into enclosure or cable glands shall be carried out to

maintain the level of protection of the equipment.

Connection of earthing or bonding conductors

The equipment shall be earthed in accordance with the

relevant code of practice. The equipment is provided by

internal connection terminal for earthing.

If the reference standards applicable for the installation

require an external equipotential connection or these

become necessary for other reasons, connect the

equipotential conductor to the external earth terminal,

identified with the earthing symbol.

The conductors used for the earth and equipotential

connection must be equipped with an eye lug. Install

each conductor according to the following instructions:

• Place the eyelet in contact with the threaded hole of

the internal or external earth terminal, positioned on

the metal box.

• Place a Grover washer or non-loosening washer

between the eye lug and the clamp screw.

• Tighten the ground terminal screw with a tightening

torque of 1.7 N×m (15 lb×in). On the internal earth

screw add some threadlocker. Tightening the screw

ensures electrical continuity.

INTRODUCTION

GIOVENZANA INTERNATIONAL B.V.

Terms of use

Special conditions for a safe usage

The FGR rotary gear limit switch is a device used to

control the number of turns or the rotation/direction

angle of industrial and building machines.

A typical application is the rolling shutter door,

overhead cranes or tackles etc. The unit, throught a

gear system and cams transmission, controls 2 or

more microswitches so, after a determined number of

revolutions, it can prepare the motor to start or stop run.

The microswitches have a calibration screw that

operates independently on each cam; so it can calibrate

the opening and closing of each micro according the

functional requirements needed.

The system gear transmission allows you to choose

different ratios with the main shaft.

The equipment must be installed only if it is completely

intact and unbroken. The product must be installed

according to the applicable code of practice, national

regulations and laws and / or international standards as

well as in compliance with the present instructions.

Do not change anything inside or outside the

equipment.

Low mechanical risk

The equipment is suitable for resisting impact energies

up to 4 J.

When impacts of energy are likely greater than 4 J,

additional mechanical protection is required around the

plastic case.

Potential electrostatic risk

The equipment is intended for fixed use and the user

must not frequently touch the equipment in service

(except for maintenance).

To avoid the potential electrostatic charge, it is

necessary to perform the following instructions during

the installation and service of the FGR:

• Do not install under direct air or other gas flow. If

these requirements cannot be met, additional external

direct flow protection is required.

• Install only when the relative humidity of the

environment is greater than 30% (stable, always or

for a long time) or in an environment with a humidity

control system.

• The metal parts of the casing must be connected

to the equipotential system in accordance with the

instructions in paragraph “Connection of earthing or

bonding conductors”.

• Do not rub the plastic cover insistently. If cleaning is

required (e.g. to remove dust) only manual operations

with wet materials are allowed.

Conditions

•

The inner components (cam MFI micros, mounting

brackets, etc.) are mounted in order to guarantee the

type of protection.

Any modification is forbidden.

Do not remove any components or micro even if they

are not used.

Every screw shall be tightened with the tightening

torque according to this document, to maintain the

degree of protection IP.

Additional holes and/or entries into enclosure are

forbidden, the only entries in the enclosure shall be

made by Giovenzana (see the information reported in

clause 1 of this document).

The type of protection and minimum degree of

protection (IP code) of the entries into enclosure

or cable glands shall be in accordance with the

equipment marking.

Any entry of the enclosure, the mounting of the entries

into enclosure or cable glands shall be carried out to

maintain the level of protection of the equipment.

Connection of earthing or bonding conductors

The equipment shall be earthed in accordance with the

relevant code of practice. The equipment is provided by

internal connection terminal for earthing.

If the reference standards applicable for the installation

require an external equipotential connection or these

become necessary for other reasons, connect the

equipotential conductor to the external earth terminal,

identified with the earthing symbol.

The conductors used for the earth and equipotential

connection must be equipped with an eye lug. Install

each conductor according to the following instructions:

• Place the eyelet in contact with the threaded hole of

the internal or external earth terminal, positioned on

the metal box.

• Place a Grover washer or non-loosening washer

between the eye lug and the clamp screw.

• Tighten the ground terminal screw with a tightening

torque of 1.7 N×m (15 lb×in). On the internal earth

screw add some threadlocker. Tightening the screw

ensures electrical continuity.

INTRODUCTION

GIOVENZANA INTERNATIONAL B.V.

Microswitch technical data

Operating temperature -25 ... +85°C

Minimum life expectancy mechanical

electrical

one million of cycles

half million of cycles

Rated thermal current Ith 8 A

Rated insulation voltage Ui 250 V

Rated impulse withstand voltage Uimp 1500 V

Rated operating current le resistive load

inductive load

8 A - 250 V

3 A - 250 V

Pollution degree 2

Protection against electric shock class II

Terminals

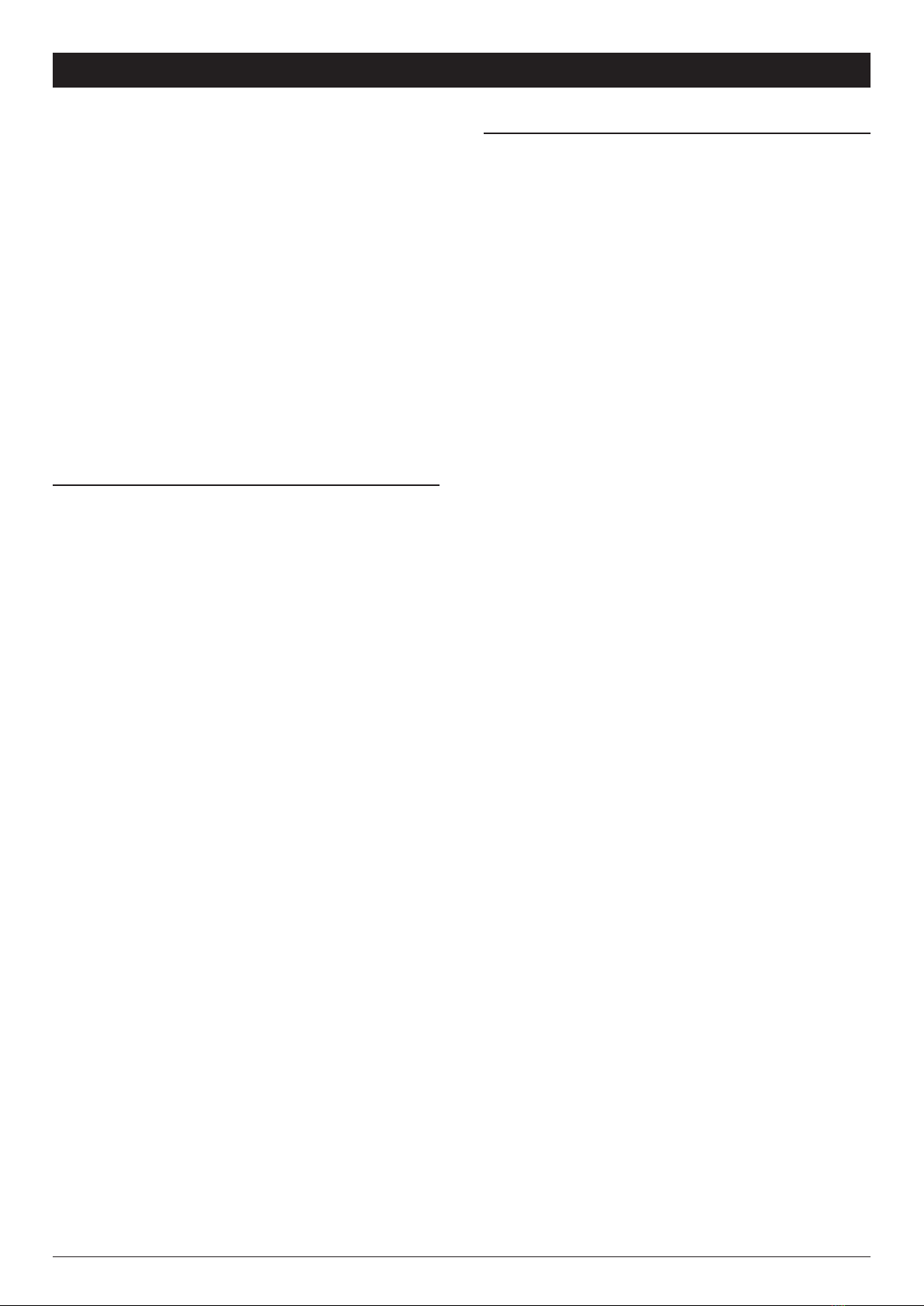

The microswitches installed can have one of the three types of terminals illustrated below:

6.3×0.8 faston screws M3 for wire 1.5 mm² screws M3 for wire 1.5 mm²

with plate protection