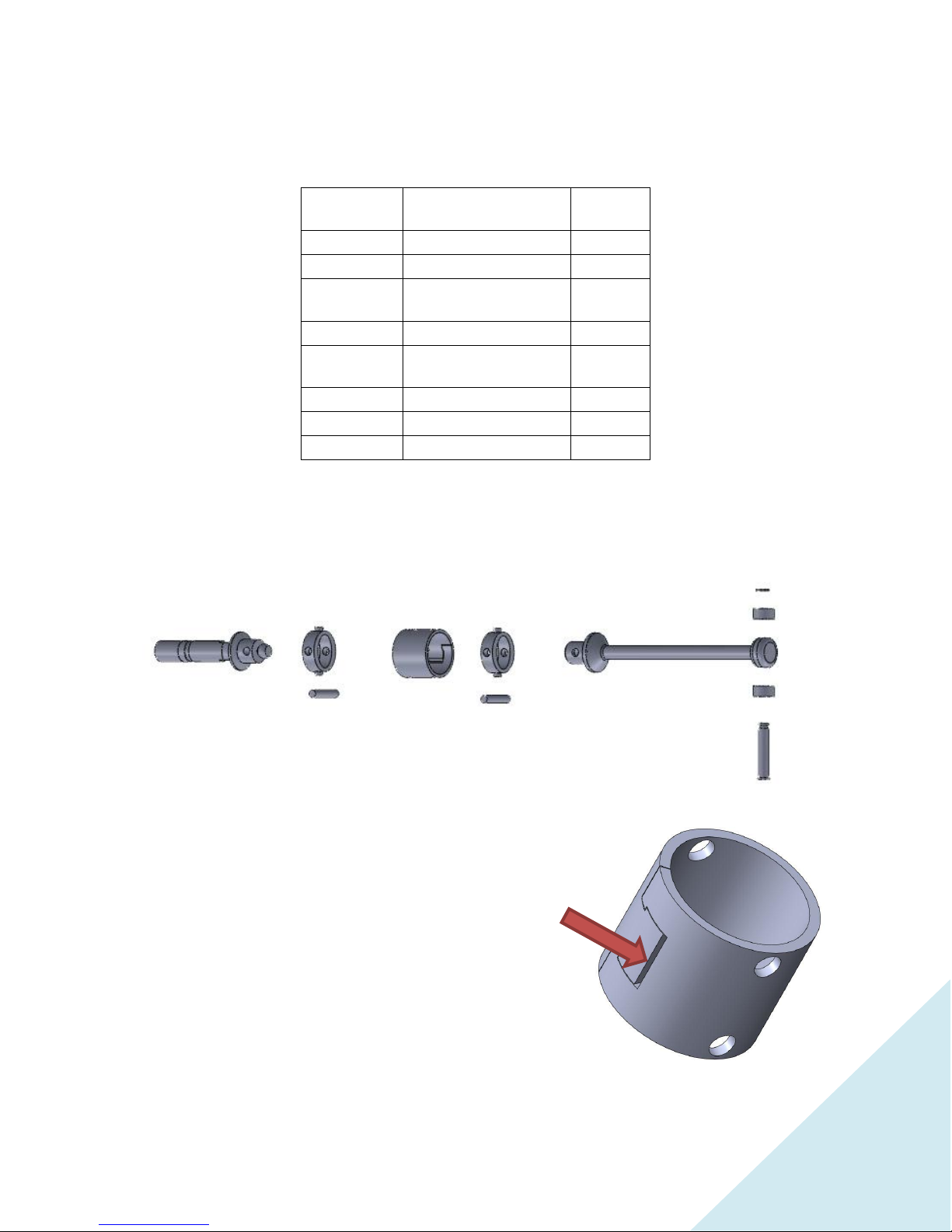

A.3.2 Arm Configuration

Repeat step A.3.1 for each of the four arms.

In the front, mount the square side of the shock mount to the outside on the arm. Use the most inward

position on the arm and the outward mounting hole on the mount for the set screw to mount the shock.

In the rear, use the round part of the shock mount to the outside. Use the second widest position on

the arm holes and the outer hole for the set screw for the shock.

NOTE: Finally, install one M3x3 set screw in the hole of the shock mount that is not being used. This will

fix the shock mount in position and prevent it from rotating.

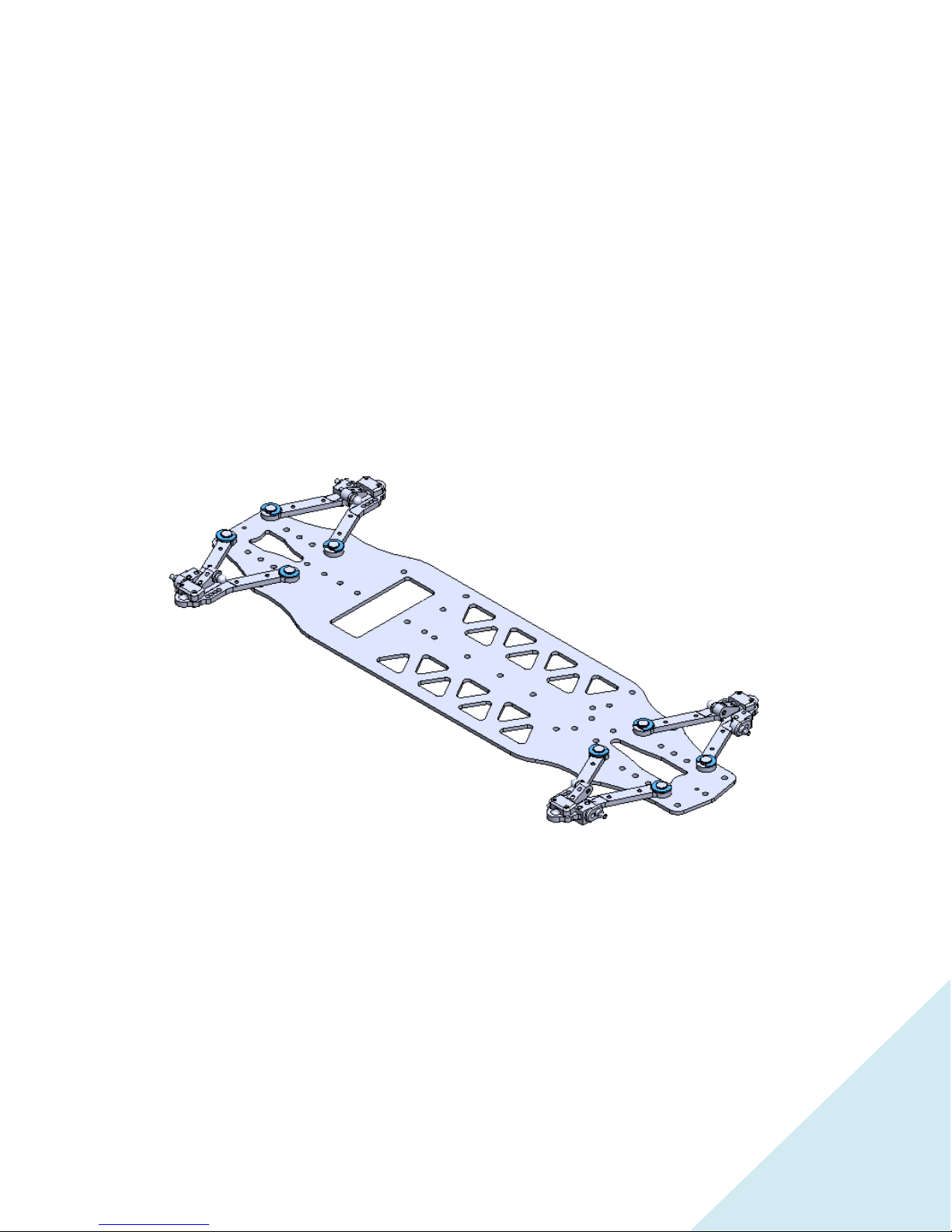

A.3.3 Arm Installation

Then, install each of the four lower arms and secure them with qty2 5050 C-Clip For Wishbones per each

lower arm, as seen above.