5. Recommendations

•Use a licensed plumber or qualified water professional to do the installation.

•Check the unit on a regular basis to see if the lamp is on (the green LED indicator will tell you if the lamp is working).

•When first installing the unit, you will need to make insure that all plumbing after the unit has been sanitized. This will

make sure that all microorganisms have been destroyed. Plumbers often fill the UV chamber with disinfectant and

flush out the pipes. They do this by opening all spigots and allowing the disinfectant to run its course through the

pipes. Professionals should do this because many disinfectants can be harmful or fatal if swallowed.

•Install carbon filters, softeners and reverse osmosis systems BEFORE the UV system. These types of filters can breed

microorganisms.

•Use a flow control device that is rated for your unit’s GPM flow rate.

6. Options

Your system may have come with optional equipment. If it did, instructions for these options are attached.

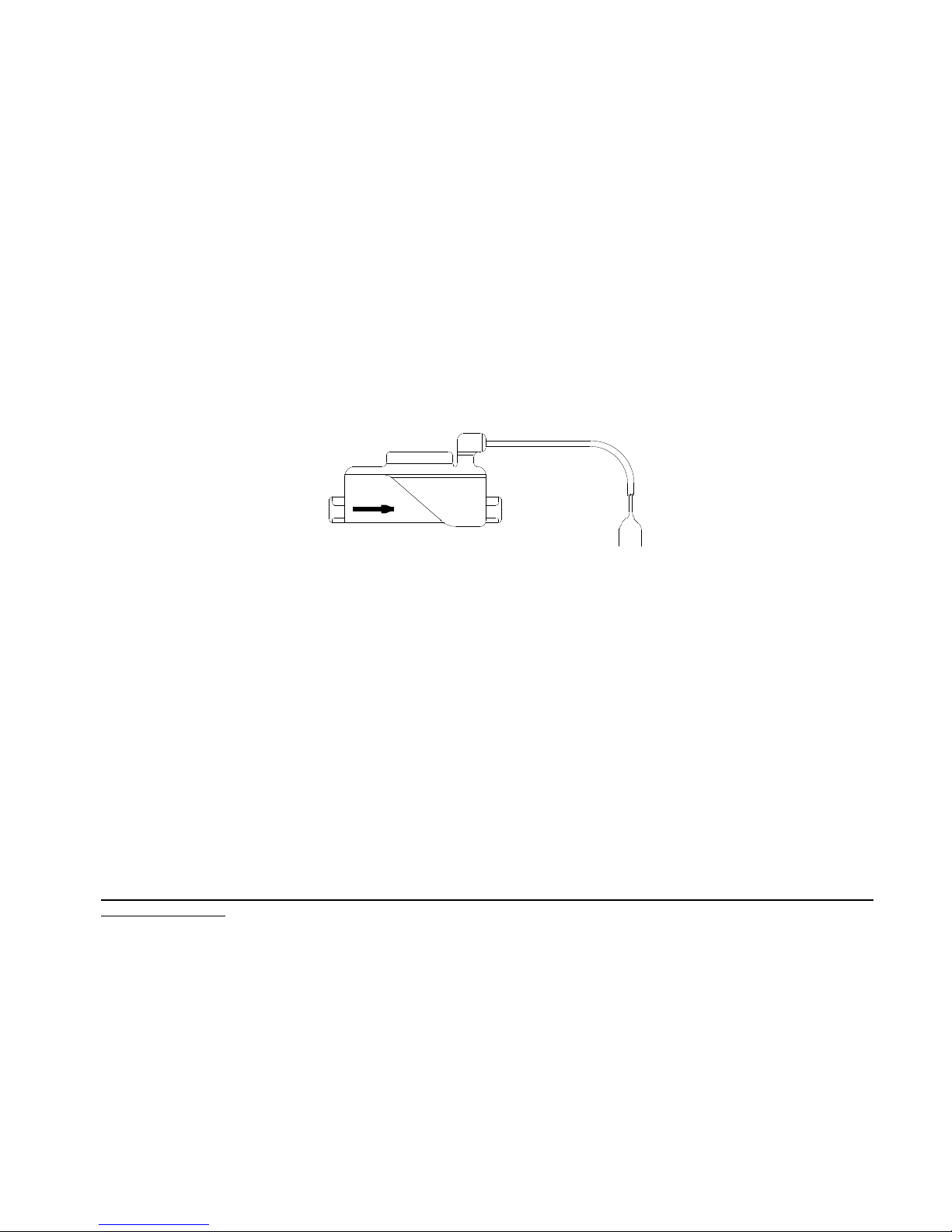

Automatic Shut-off Valve aka Normally Closed Solenoid

Your system may have come with an optional automatic solenoid valve.

This device will stop the water flow if the UV lamp goes out or if the UV intensity falls. It is considered a “normally

closed” valve. This means that when there is no power to it, it closes. This will occur during a power outage or lamp

failure.

The solenoid will work off of a signal from the ballast, which indicates lamp out. If lamp fails, then the solenoid will shut

off the water supply.

The solenoid will also work off of a signal from the UV monitor, when the UV intensity has fallen to an unsafe level. In

the event of water stoppage, you will need to correct the problems.

Reasons for stoppage include: Power failure, Lamp is out, Ballast is out, UV lamp is failing, Solenoid is damaged

There is a manual override on some of the valves. Call your water professional in case of an emergency. The manual

valve is a white toggle switch. In order to open the valve, it must have power. This is generally provided by the UV

system, but in emergencies, power can be brought directly to the valve.

The main power box control will have leads for attaching the solenoid. These leads will need to be connected to the

leads on the actual solenoid valve. The solenoid will have come with connectors.

The solenoid valve will have an arrow on it indicating flow direction. Please install it the solenoid so that the path of the water

goes with the arrow.

Manual Quartz Cleaning System

Your system may have come with an optional manual quartz cleaning system. This device will allow you to

clean the quartz sleeve without having to disassemble the disinfection chamber.

! WARNING ! The plunger may be forced out when water pressure builds up. When installing the unit, make

sure that you stand clear of the plunger when pressurizing the system.

In order for the system to work at optimum performance, you must clean the quartz on a periodic basis. To

clean quartz, pull the plunger toward you and then push it in again. Do this a few times a month.

You may need to change the o-rings on the wiper on a periodic basis. Please open the system once a year to

inspect the quartz and the wiper rings.