1

2

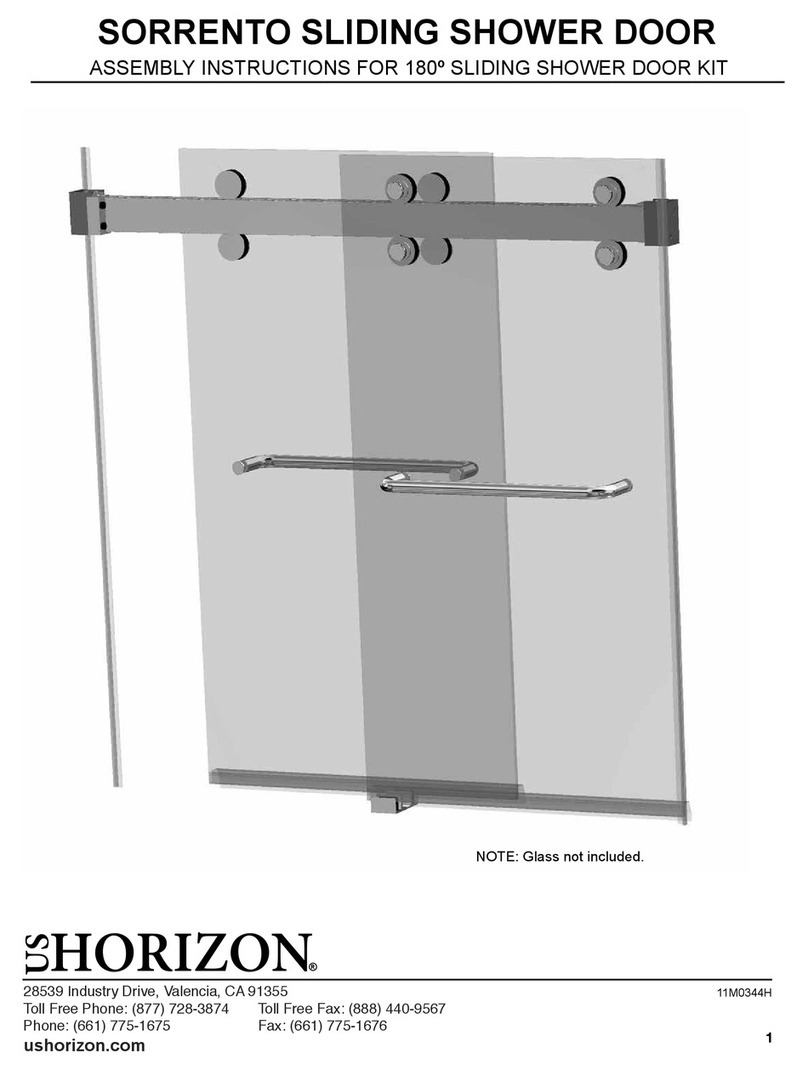

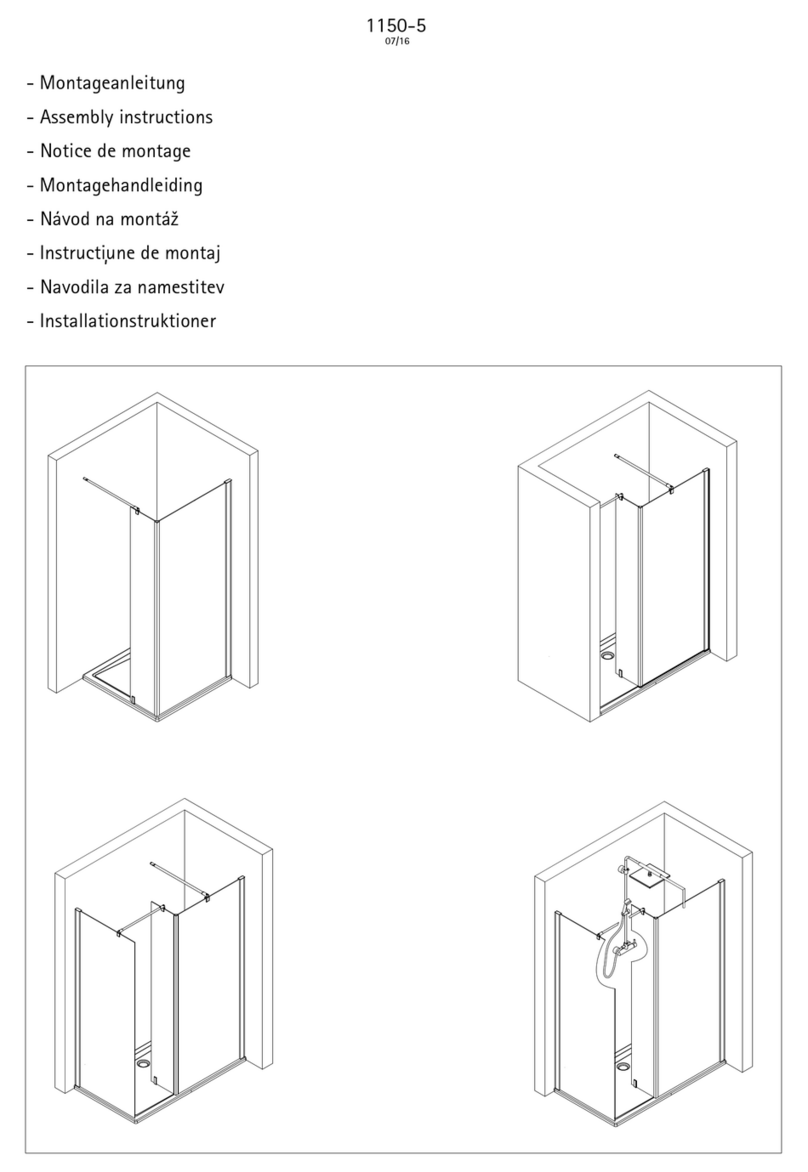

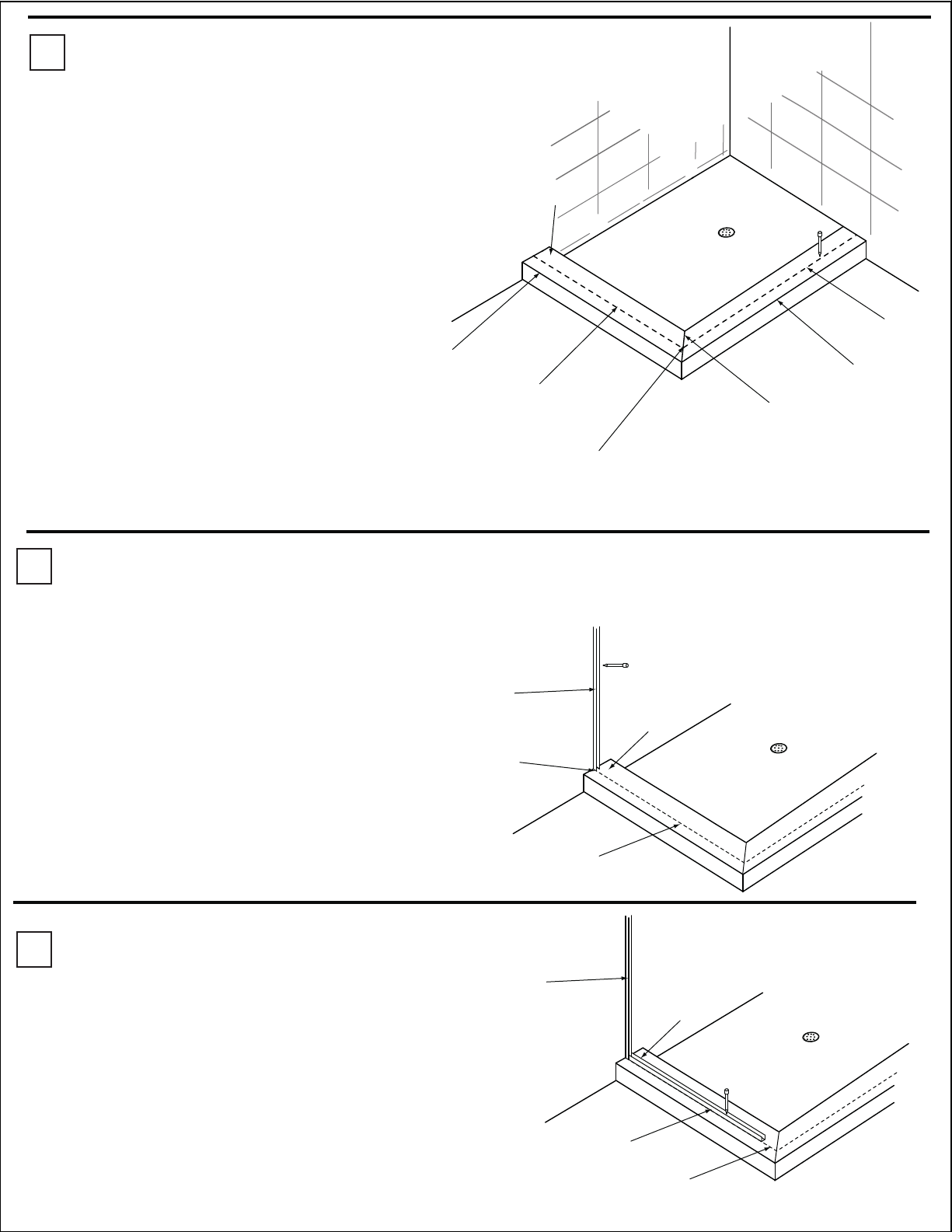

Sketch 1 A

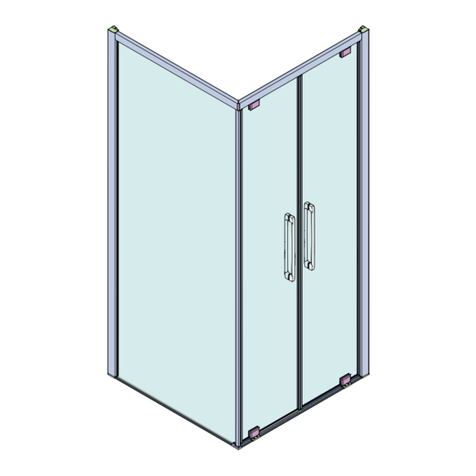

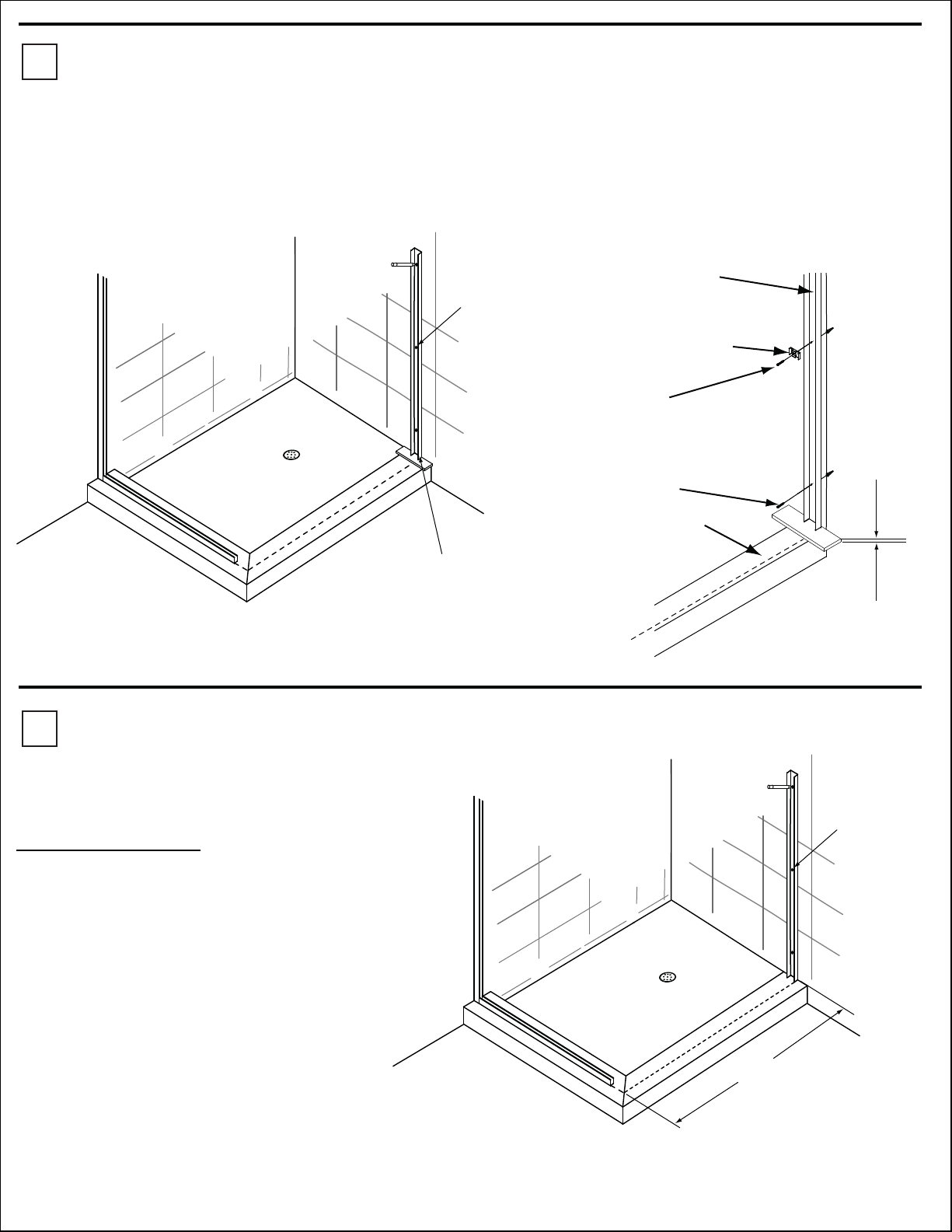

Sketch 2 A

“A”

Installation Instructions for GlassCrafters Epic By-Pass Shower Enclosure

IMPORTANT: Read all instructions carefully and become familiar with all parts before installation.

Cleaning: Never use scouring powder, pads or sharp instruments on metal work or glass panels.We recommend

the use of a squeegee after each shower to eliminate water spots on the inside of the glass panels.

An occasional wiping down of the glass panels and anodized aluminum parts with a mild detergent,diluted in water,is

all that is needed to keep your Shower /Tub Enclosure looking brand new.

Unpacking: Care should be taken unpacking your Shower Enclosure.Place the Glass Panels in an upright,

Safe location to avoid damage.Never place glass directly on hard surface.

A Box cutter should not be used to open box.

Please remove all staples from the box prior to unpacking metal and glass.

IMPORTANT:

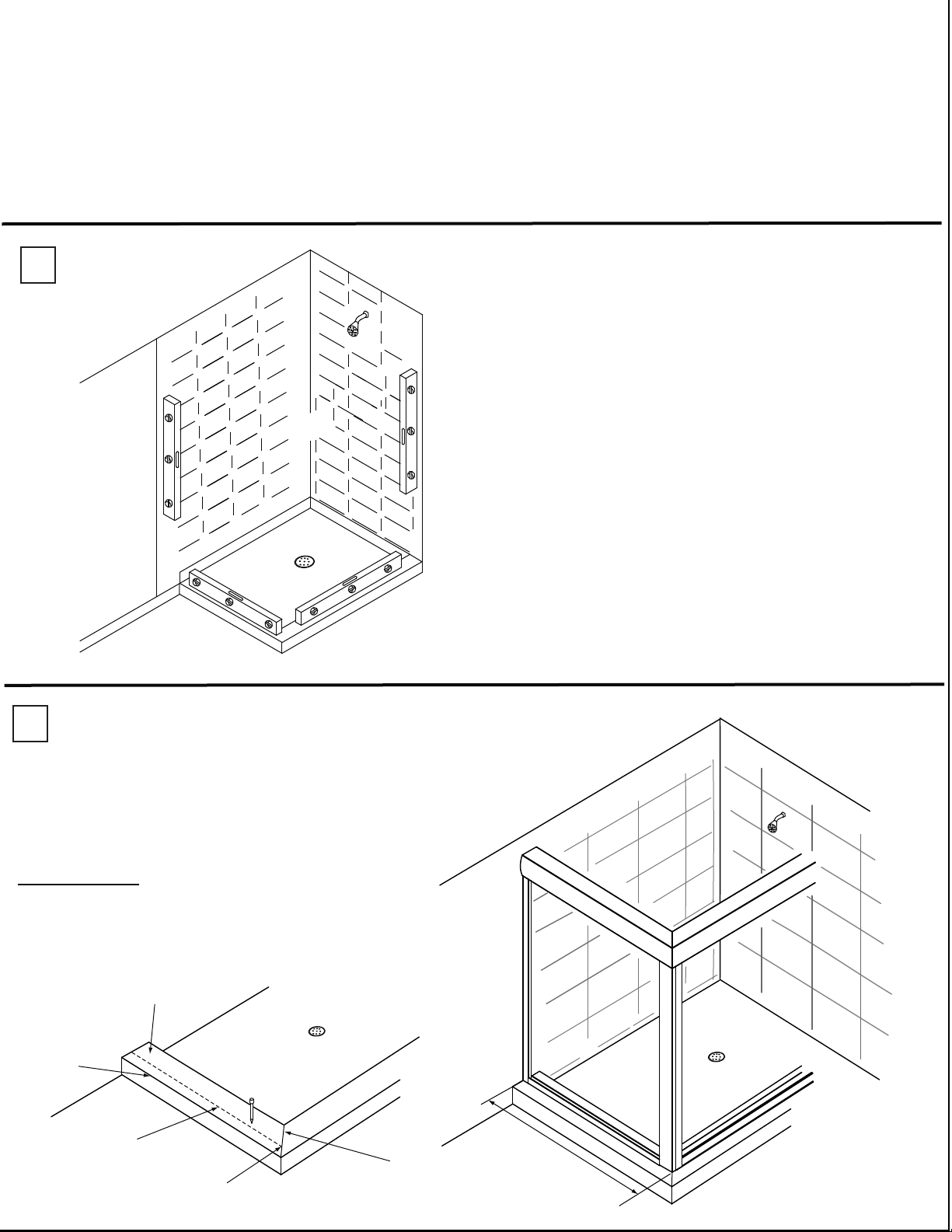

Determine if your Tub/Shower Stall Enclosure ledge is

Level and Wall are plumb as shown in Sketch 1A.

If they are out of Level/Plumb, by more than 1/4”, STOP!

and call Customer Service. The Phone number is

1-888-683-1362

A Base filler and /or Wall Jamb Filler are recommended

for obtaining proper adjustment;

both are available through Customer Service.

If they are Level/Plumb, or out of Level/Plumb for less than

1/4” proseed with installation.

The Base Channel # 22 for return panel is cut per size on factory.

Locate that channel among supplied parts and measure It .

Add 2 5/8”to the measurement. That is the size from return wall

to the front of unit. See Sketch 2A for detail.

“A” = BASE CHANNEL #22 + 2 5/8

Using pencil and ruler draw a line (OD Line) on the curb

equal to size ”A”. Make sure that Open-end

of the line (opposite to wall end) ends at

curb-break line. Also make sure that it

is parallel to curb’s front edge. See Sketch 2A for detail.

Curb

OD Line

Curb’s Front

Edge

Curb-Break

Line

Open-end of Line

ends at Curb-Break Line Pa

e 4 of 15 4/2/2010